SS-V: 5080 Rigid Punch Plasticity

Test No. VNL09 Find out reactions at the punch pressed on large block for perfectly plastic and isotropic hardening materials.

Definition

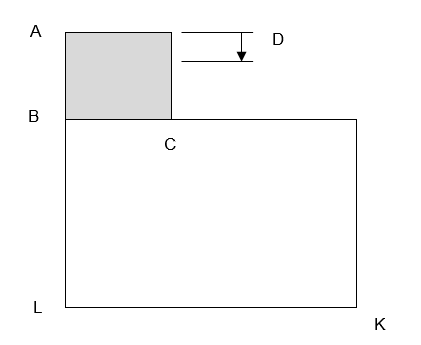

Figure 1.

Dimensions: AB = 40 mm, BC = 80 mm, BL = 160 mm, LK = 200 mm

- Properties

- Value

- Modulus of Elasticity

- 1.e+3 MPa

- Poisson's Ratio

- 0.3

- Elastic perfectly plastic with yield stress 1 MPa

- Isotropic hardening with tangent modulus 0.1e+3 MPa

Results

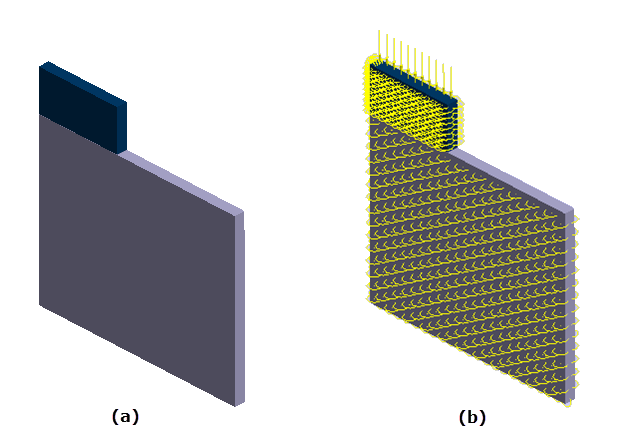

Figure 2.

| SimSolid Reaction, N | Reference Reaction, N | |||

|---|---|---|---|---|

| D, mm | Perfect Plasticity | Hardening | Perfect Plasticity | Hardening |

| 0.04 | 29.57 | 29.57 | 30 | 30 |

| 0.12 | 86.95 | 87.27 | 86 | 87 |

| 0.14 | 99.93 | 100.65 | 99 | 100 |

| 0.16 | 108.22 | 111.17 | 109 | 113 |

| 0.18 | 108.87 | 113.03 | 110 | 114 |

| 0.24 | 111.75 | 122.20 | 111 | 125 |

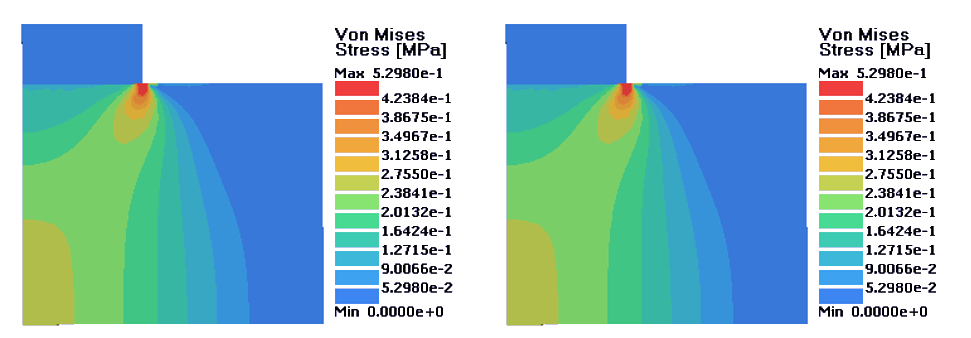

Figure 3. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.04 mm

Figure 4. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.12 mm

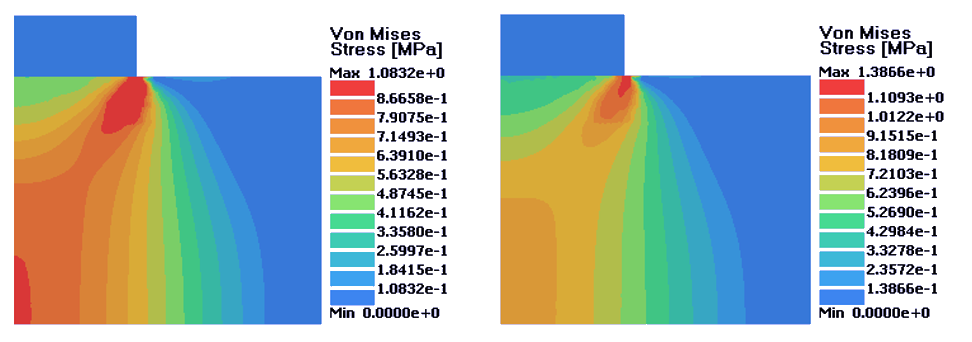

Figure 5. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.14 mm

Figure 6. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.16 mm

Figure 7. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.18 mm

Figure 8. Left: Perfectly Plastic Material; Right: Isotropic Hardening Material. D = 0.24 mm