ACU-T: 5001 Blower - Transient (Sliding Mesh)

Prerequisites

This tutorial provides the instructions for setting up, solving, and viewing results for a transient simulation of a centrifugal air blower utilizing the sliding mesh approach. In order to run this tutorial, you should have already run through ACU-T: 5000 Blower - Steady (Rotating Frame) and kept the solution in your working directory. It is assumed that you have some familiarity with HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Prior to running through this tutorial, click here to download the tutorial models. Extract ACU-T5001_BlowerTransient.hm from HyperWorksCFD_tutorial_inputs.zip.

Since the HyperWorks CFD database (.hm file) uses the ACU-T:5000 Blower-Steady model, this tutorial skips the geometry clean-up and inlet boundary conditions as well as the mesh settings.

Problem Description

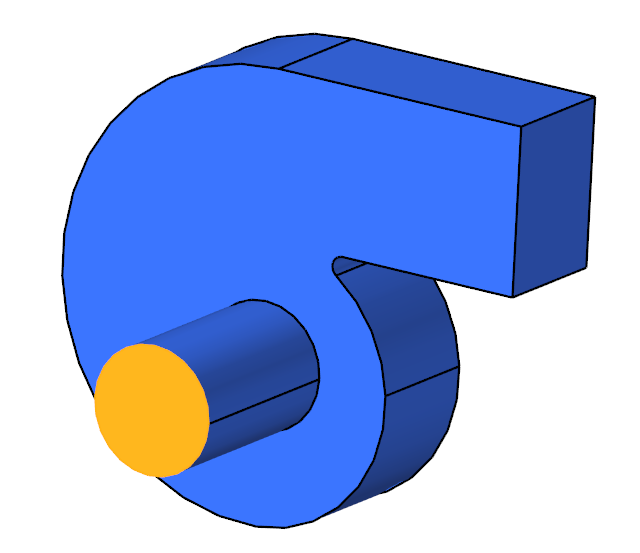

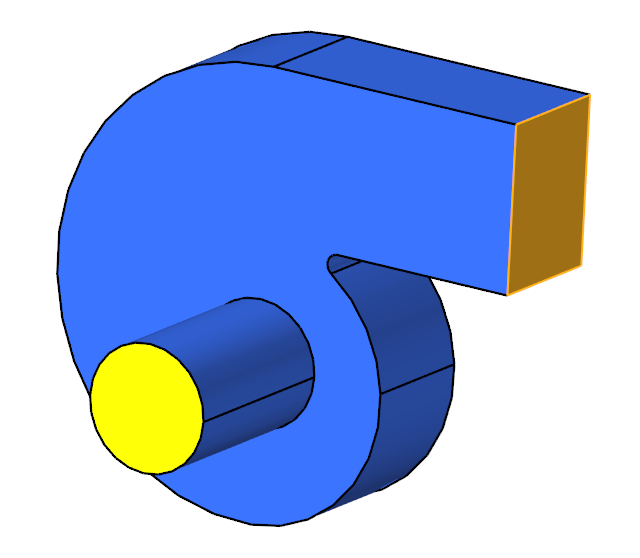

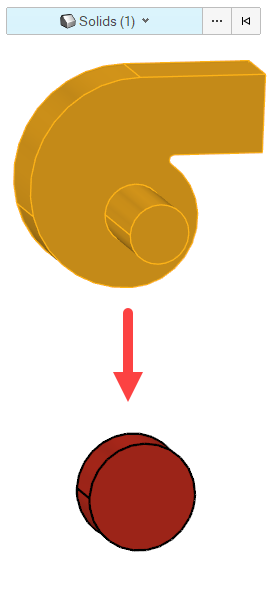

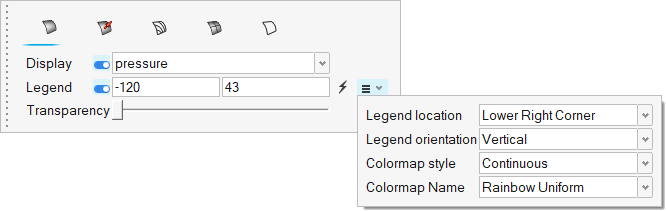

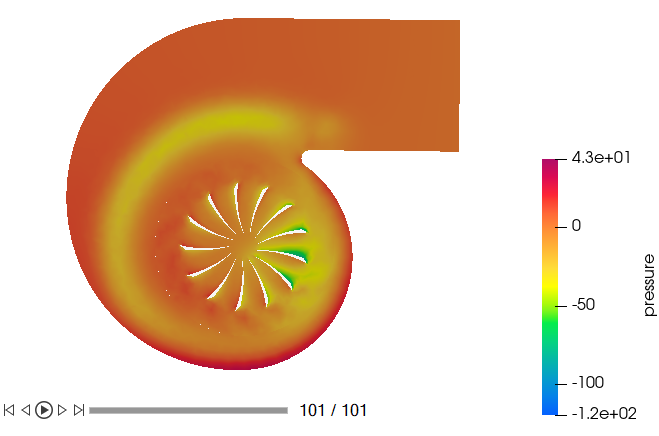

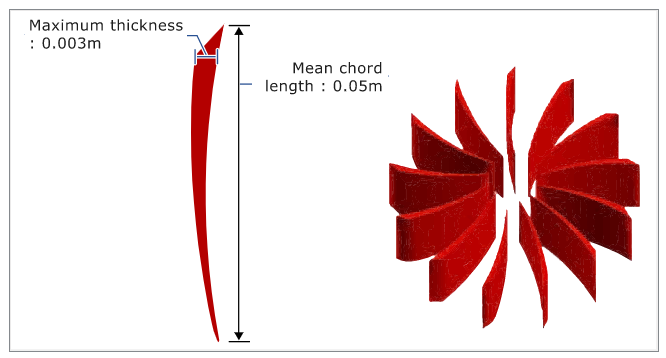

The problem to be addressed in this tutorial is shown schematically in Figure 1 and Figure 2. It consists of a centrifugal blower with forward curved blades. The fluid through the inlet plane enters the hub of the blade wheel, radially accelerates due to centrifugal force as it flows over the blades, and then exits the blower housing through the outlet plane.

Figure 1. Schematic of Centrifugal Blower

Figure 2. Schematic of Fan Blades

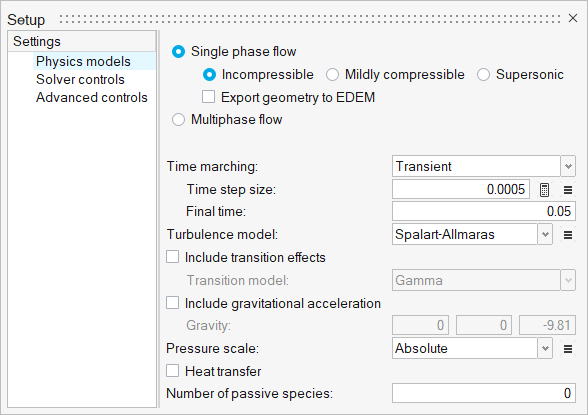

To capture the dynamic motion of the impeller blades, the simulation must be transient. The time step size is determined by:

where ω is the blower rotational speed. It should be noted that a time step size sensitivity study should always be performed to establish appropriate time step size when analyzing a new application.

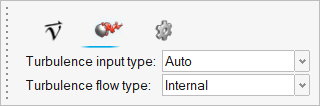

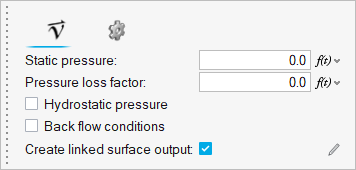

The CFD analysis of this problem offers detailed information about the flow through a centrifugal blower. To investigate this behavior, it is necessary to select an appropriate set of boundary conditions to use. There are two different methods that are commonly used. One approach is to specify the mass flow rate at the inlet of the blower and allow AcuSolve to compute the pressure drop, that is, flow forces simulation. Another option is to specify the stagnation pressure at the inlet and allow AcuSolve to compute the flow rate that results from this specified pressure change between the inlet and outlet. The boundary conditions used in this example are the latter. That is, the inlet is taken as stagnation pressure rather than mass flow rate so that AcuSolve calculates mass flow rates and pressure rise based on impeller rotation.

The fluid in this problem is air, which has a density of 1.225 kg/m3 and a viscosity of 1.781 X 10-5 kg/m-s.

Start HyperWorks CFD and Open the HyperMesh Database

Set Up Flow

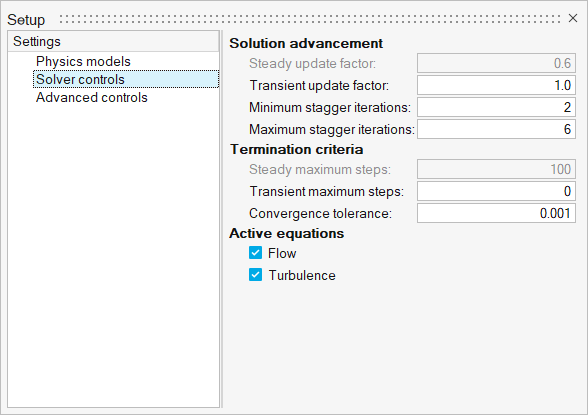

Set Up the Simulation Parameters and Solver Settings

Define Flow Boundary Conditions

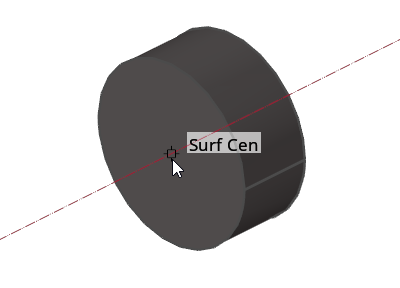

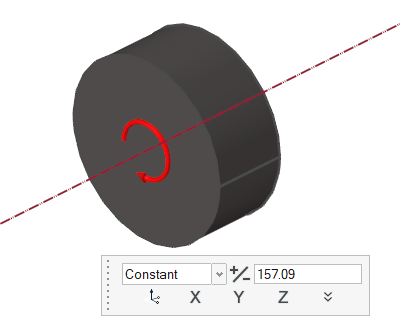

Set Up Mesh Motion

Define the Mesh Motion Type

Define the Rotating Mesh Motion

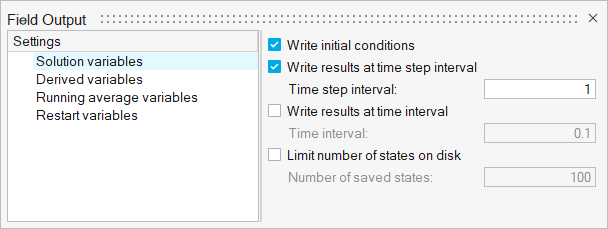

Define Nodal Output Frequency

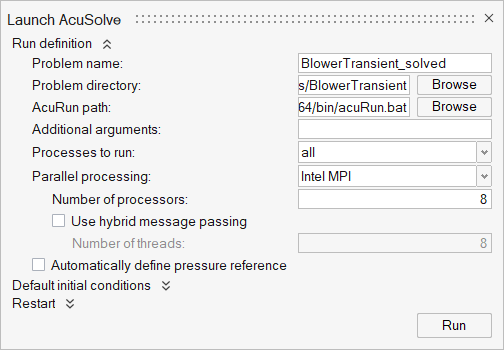

Run AcuSolve

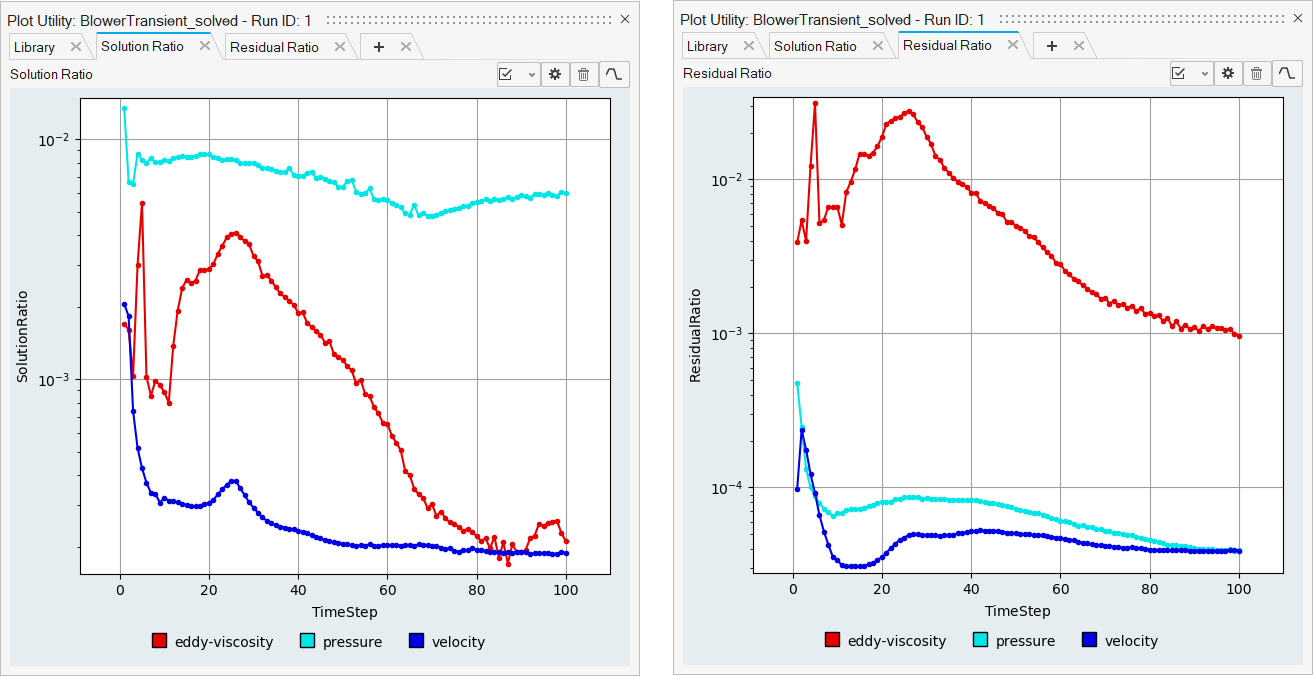

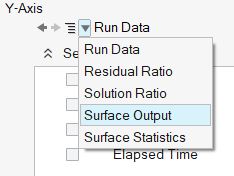

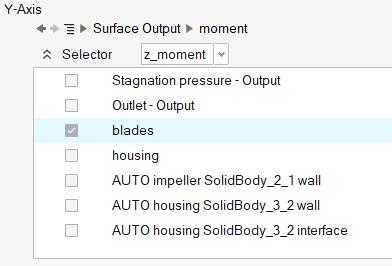

Plot Surface Output

Post-Process the Results with HW-CFD Post

Summary

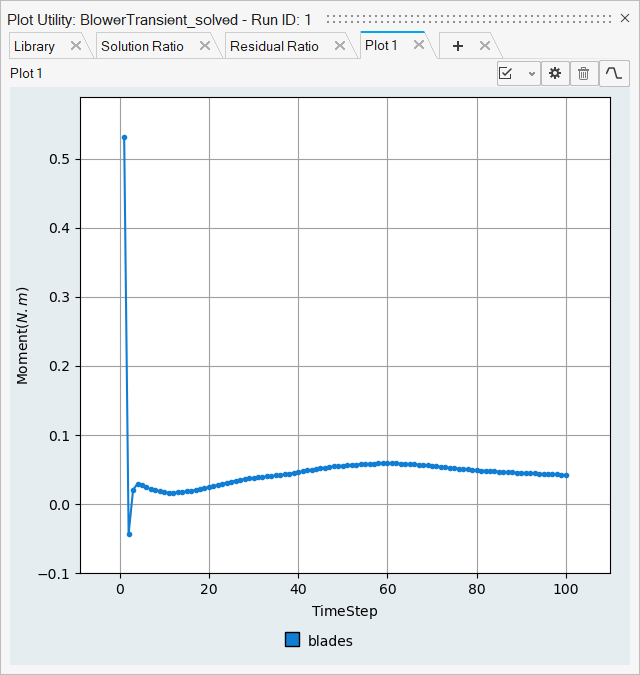

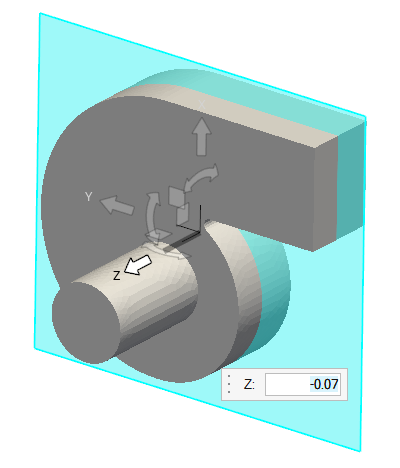

In this tutorial, you worked through a basic workflow to set up a transient simulation with a sliding mesh in a centrifugal blower. You started by importing the mesh; once the case was set up, you generated a solution using AcuSolve. Then, you computed the blower momentum using the Plot tool and created a contour plot for pressure on a cut plane using HyperWorks CFD post.