Shell To Solid Conversion

The Shell To Solid Conversion tool provides functionality to generate solid elements and material orientations from a ply based shell model.

Restriction: Only available in the Nastran,

Abaqus, and OptiStruct solvers.

- From the menu bar, click Aerospace > Composites > Shell To Solid Conversion.

-

In the Select entities field, select entities on which to perform shell to

solid conversion.

- Laminates

- Plies

-

In the Solid Elems field, select an option that controls the number of solid

elements generated through thickness.

- Create solids for each layer – generate single solid elements for each input ply layer.

- Create single solids for all layers – generate single layered solid element through thickness. Output is either continuum shell of layered solid depending on the solver profile, element type setting (can be changed from 2D or 3D > elem types > 2D & 3D panel under penta6 and hexa8) and template property.

- Create multiple solids using dummy ply separation – generate multiple layered solid elements through thickness. The number of layered solid elements is determined by the number of “Dummy Plies” in the laminate. Output is either continuum shell or layered solid depending on the solver profile, element type setting (can be changed from 2D or 3D > elem types > 2D & 3D panel under penta6 and hexa8) and template property.

-

In the Component field, select the method for controlling solid elements

generated in conversion:

- Create comp for each ply – a new component is created for each input ply

- Current collector – all solid elements created are placed in the current component

- Create single comp for all plies – a single new component is created

- Use existing shell component – solid elements are placed in the component containing the shell element from which they are generated

- Select Fill gaps to create pyra and penta elements to fill voids created by ply drops.

- Select Delete Shells to delete shell elements of ply-based model after solid elements are created.

-

Select Create Props to create solid composite properties

assigned to created solid elements.

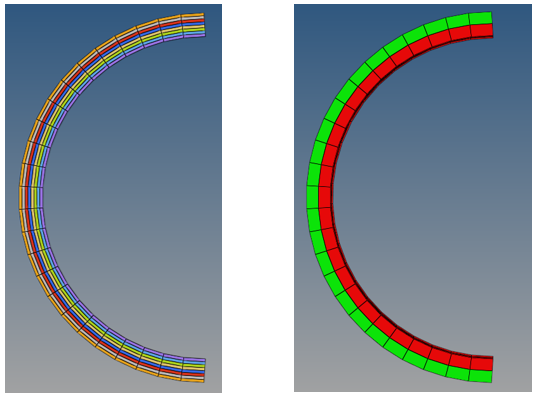

Figure 1.

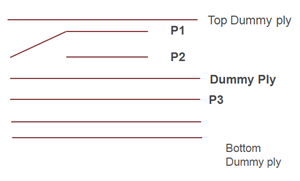

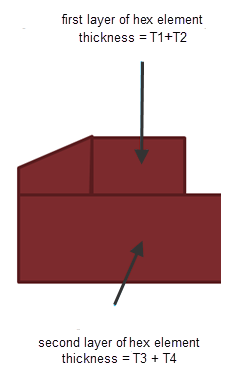

Figure 2. Dummy Ply for Create Multiple Solids Using Dummy Ply Separation

Convert the Shell Composite Model to the Variable Thickness Solid Layer Composite Model

- Develop a composite shell model with Shell_section_composite property. Stop the procedure with ply realization. Do not convert the ply to a zone based model using laminate realize.

-

Change the 3D element type to SC8R and SC6R in the 3D subpanel on the Element

Types panel.

This will assign continuum shell properties to the newly created solids.

- Use the Shell to Solid Conversion dialog to select either Create solids for each layer or Create single solids for all layers.

- Select Current Collector from the Component drop down.

- Check the Fill gaps option for Create solids for each layer.

- Check the Delete Shells option.

- Check the Create Props option.

-

Select all of the plies and click Convert.

This creates a solid composite. You can see the ply direction, even on the new solid elements.Note: If you create single solids for all layers, discontinuous elements may be created near the ply drop off areas. These nodes should be equivalenced to pass the solver runs.

Create Multiple Solids Using Dummy Ply Separation

- Develop a composite shell model with Shell_section_composite property. Stop the procedure with ply realization. Do not convert the ply to a zone based model using laminate realize.

-

Change the 3D element type to SC8R and SC6R in the 3D subpanel on the Element

Types panel.

This will assign continuum shell properties to the newly created solids.

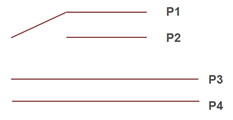

- Create dummy plies (zero thickness, zero ply angle) to separate the plies into a group. You are also required to create top and bottom dummy plies in addition to the separation dummy plies. Dummy plies can be created using the Edit Ply dialog and assigning all the elements in the model to that dummy ply so that it runs through the entire model.

- Next, the dummy plies need to be assigned to the laminate. It is required to add top and bottom dummy plies in addition to inserting separation dummy plies. This is accomplished using the Edit Laminate dialog.

- Select Shell To Solid Conversion from the Aerospace menu to open the Shell to Solid Conversion dialog. For Solid Elems select Create multiple solids using dummy ply separation. The Fill gaps checkbox is automatically selected as long as you define the top and bottom extra dummy plies in the laminate in addition to the separation dummy plies.

-

Select the laminate that is required to be converted and then click

Convert.

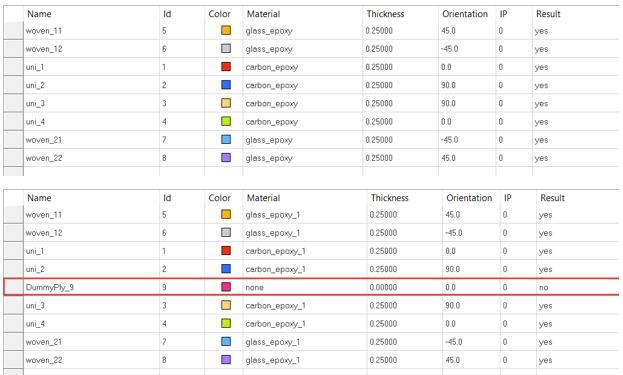

Figure 3. Original Shell Model Ply

Figure 4. Original Shell Model Ply

Figure 5. Updated Shell Model Plies