Biasing

Biasing allows you to control the shape of a mesh when applying handle perturbations.

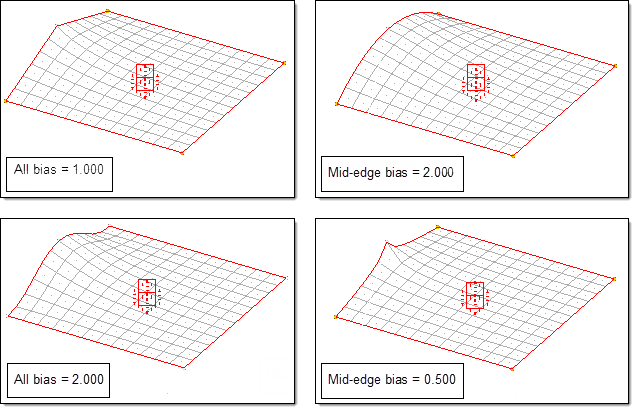

Figure 1. Biasing for a 2D Domain. The model at the upper left has all five handles with the default biasing value of 1.000. The model at the upper right shows the four corner handles with a biasing value of 1.000, and the mid-edge handle with a biasing value of 2.000. The model at the lower left has all five handles with the default biasing value of 2.000. The model at the upper right shows the four corner handles with a biasing value of 1.000 and the mid-edge handle with a biasing value of 0.500.

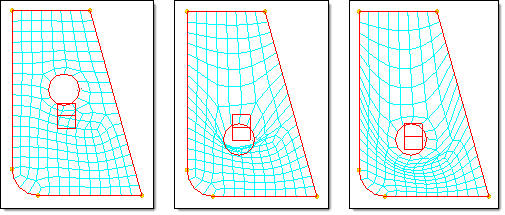

Figure 2. Biasing to Reduce Mesh Distortion. When the hole is moved downward with a biasing factor of 1.000 for the handle at the hole, the mesh folds over due to the influences of the other handles (middle frame). When the biasing value of the handle at the hole is increased to 3.000, the mesh unfolds (right frame).

Biasing can be applied retroactively after a morphing operation. After applying a morph, you can change the biasing value by selecting the make retroactive checkbox, and have the current list of applied morphs updated to reflect the new biasing values. This is useful in selecting a good biasing value to apply for a given morph. Apply the morphs and change the biasing values retroactively until you get the shape that you want.