SS-T: 3000 Non-linear Separating Contact and Bolt Pretensioning, Hanger Beam

Perform non-linear separating contact analysis and setup bolt/nut tightening loads.

- Prerequisites

- Some features used in this tutorial are only available in SimSolid Advanced version. Please switch to Advanced to complete this tutorial.

- Purpose

- SimSolid performs meshless structural

analysis that works on full featured parts and assemblies, is tolerant of

geometric imperfections, and runs in seconds to minutes. In this tutorial,

you will do the following:

- Perform assembly analysis

- Perform non-linear separating contact analysis

- Use SimSolid bolt tensioning functions

- Compare SimSolid results with those obtained in traditional FEA.

- Model Description

- The hanger beam model in this tutorial has 70 parts, 16 bolts/nuts, and 32 washers.

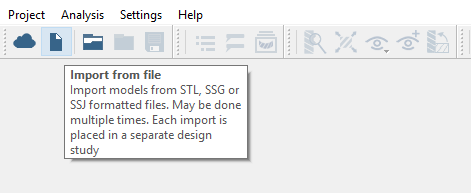

Import Geometry

Create Connections

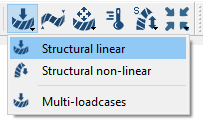

Create Structural Linear Analysis

Create Immovable Supports

Create Force

Change Max Number of Adaptive Solutions

- In the Project Tree, double-click on Solution settings.

- In the dialog, set the objective to Custom and increase the number of adaptive solutions to 4.

- Select the Adapt to features check box.

- Click OK.

Assign Materials

Run Analysis

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

Open Project

Create Non-linear Separating Contact Analysis

Edit Contact Conditions

Run Analysis

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).

Compare Results

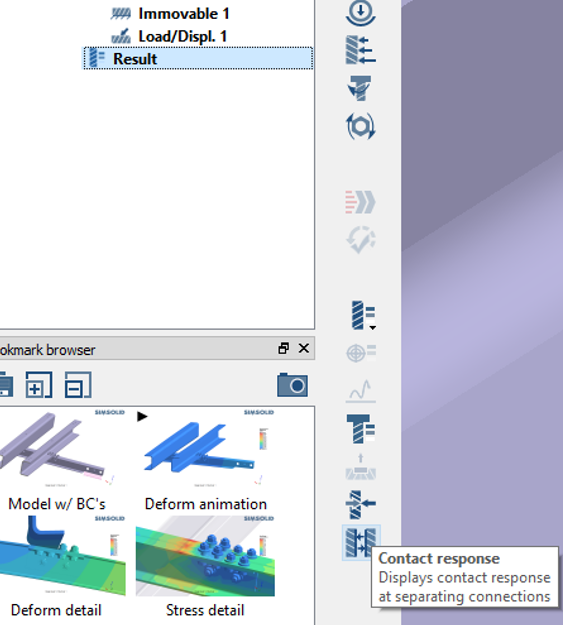

View Separation and Contact Forces

Setup Bolt/Nut Tightening

Run Analysis

- In the Project Tree, open the Analysis Workbench.

-

Click

(Solve).

(Solve).