可以将螺栓力施加于 SimSolid 中的螺栓和螺母几何体。.

螺栓和螺母

在

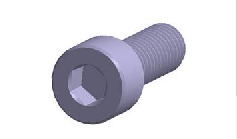

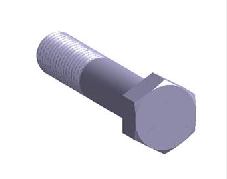

SimSolid 中,螺栓会由其几何属性自动标识。螺栓必须有圆柱形的主体和基于六面体的头部。六角形可以位于螺栓头部的外径或内径上。可以使用类似的基于六角的几何特征来识别螺母。

Figure 1.

Figure 2.

在

SimSolid 中,预紧力载荷可以施加于以下各种几何体,包括:

- 盲螺栓

- 螺栓和螺母

- 螺纹杆上的螺栓

- 通用杆或手柄上的螺母

扭矩 M 与轴向力 F 的关系

M 是预紧结束时实现的最大力矩,它由螺母与结构之间的摩擦力所产生的力矩平衡。

为简单起见,假设接触中的法向力均匀分布,因此接触压力如下:

(1)

(2)

R0 和 R1是接触载荷点的内半径和外半径。摩擦力分布力将是

,其中 f 是摩擦系数。

在极坐标系中,摩擦力相对于螺栓轴的基本力矩为:

其中,r 是到轴的距离,而 dR 和 dTet 分别是半径和角度差。

对接触区域上的基本力矩进行积分,以获得以下结果:

该方程式将施加的扭矩、M 和轴向力联系了起来。

轴向力

轴向力取决于结构和螺栓刚度,以及螺母相对于螺栓的位置:

(3)

K 为结构刚度系数,D 为相对位移。

相对位移可以用以下表达式表示:

这里,N 是螺母圈数,H 是螺距。因此,

(方程式 A)

假设在第一次分析过程中描述了一个螺母转动 (N(1)=1),并从分析中找到了对应的轴向力 F(1)。这种情况下的结构刚度系数可以定义为:

(4)

这意味着:

。

现在,您可以将扭矩与转数相关联:

(5)

因此,为了实现规定扭矩 M,在 N=1 的情况下进行第一次分析之后,必须使用以下公式进行第二次分析(第二次收敛迭代):

(6)

一般来说,在迭代 (i+1) 时,施加的转数如下:

(7)

这里,N(i) 是在前一次迭代时施加的转数,F (i) 是在前一次迭代时评估的结果轴向力。这些对所施加的转数的修正很重要,因为在迭代过程中,求解得到了细化,这改变了上面公式 A 中的结构刚度因子 K。所以,K 不是常数,而是依赖于传递 K(i)。