Solution Sequences

OptiStruct can be use different solution sequences for aircraft analysis.

- Type

- Description

- STATICS

- Linear Static or Nonlinear Static Gap Analysis

- MODES

- Normal Modes Analysis

- BUCK

- Linear Buckling Analysis

- DFREQ

- Direct Frequency Response Analysis

- LGDISP

- Large Displacement Nonlinear Static Analysis (available as PARM card entry)

- HEAT

- Linear Steady-state or Transient Heat Transfer Analysis

- FATIGUE

- Fatigue Analysis

Static Analysis

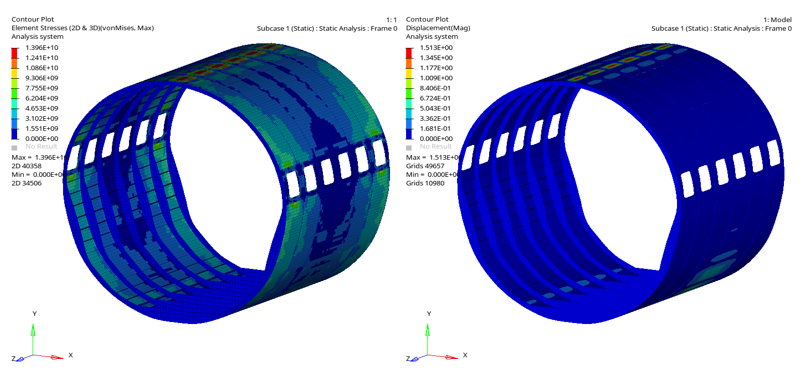

Figure 1. Stress and Displacement Contours for Static Analysis of a Fuselage Section

For further information, refer to Linear Static Analysis.

Nonlinear Static Analysis

- Material nonlinearities

- Geometric nonlinearities

- Presence of nonlinear forces

- Contact nonlinearities

Inertial Relief Analysis

- PARAM, INREL, -1 is used when certain boundary conditions are specified.

- PARAM, INREL, -2 is used when no boundary conditions are specified.

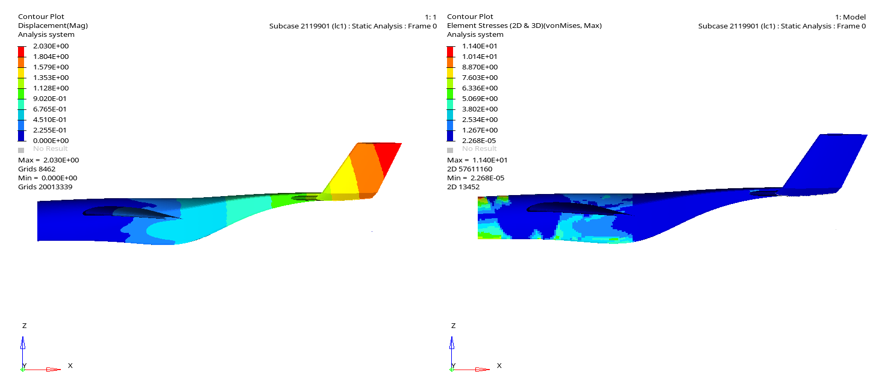

Figure 2. Displacement and Stress Contours for Inertia Relief Analysis

Figure 2 shows the results from an Inertia Relief Analysis performed on a fuselage model.

Normal Modes Analysis

- Under constrained and loose components

- The rotating speed which matches the natural frequencies in case of the analysis of a blade or a rotor

- The areas to be constrained or loaded.

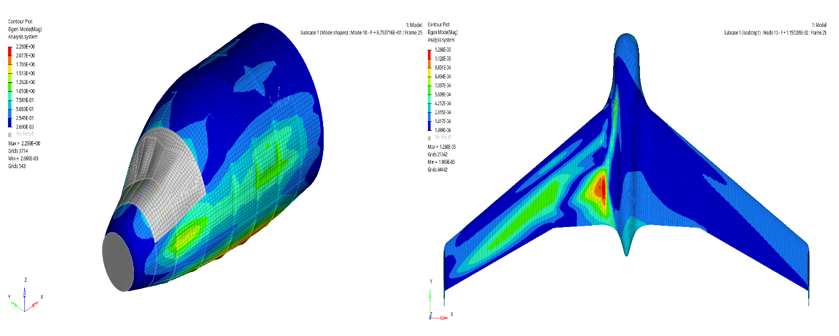

Figure 3. Normal Modes Analysis of a Fuselage and Drone

Figure 3 shows the results from the Normal Modes Analysis for a fuselage and a drone. Both models have free-free boundary conditions.

Frequency Response Analysis

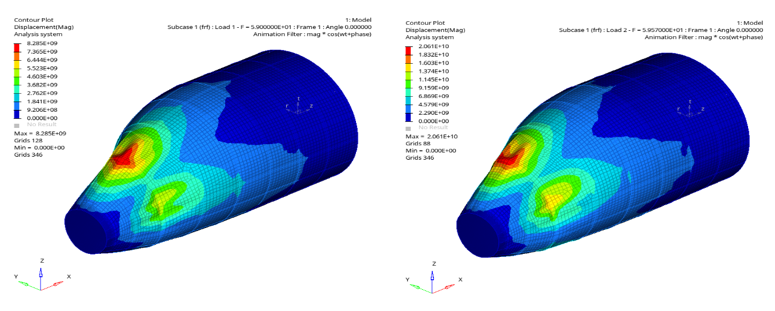

Figure 4. Frequency Response Analysis of a Fuselage Section

Model File

Refer to Access the Model Files to download the required model file(s).

The model file used here includes:

Fixedwing_modal.fem