Standalone Run of FVM Airbag

FVM airbag should be run standalone to verify correct deployment behavior and airbag characteristics. The FV merging parameters and time step control can be modified to reduce simulation time while still providing realistic results.

/DT/FVMBAG/1

1.5 1.0e-05

/FVMBAG/MODIF

666000001

1 0.010 0.001 1Variation of time step scaling coefficient and global merging parameter may be necessary to provide proper time step and number of FV at the end of the simulation.

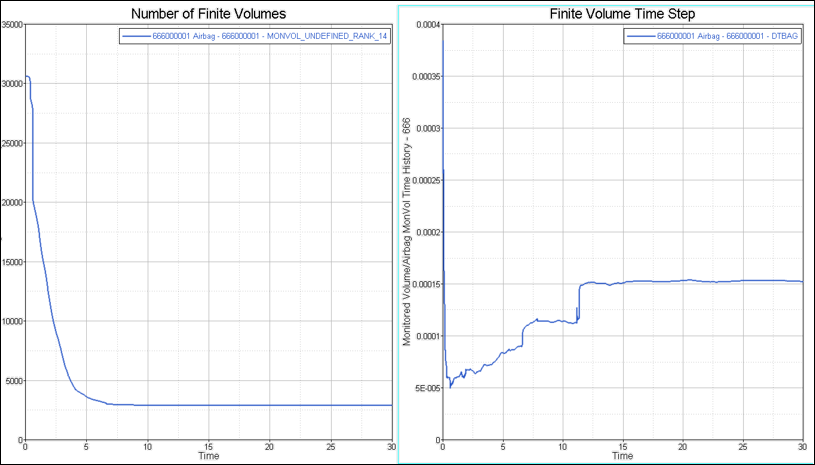

Figure 1.

The number of finite volumes should reduce smoothly to 2-10% of initial number of finite elements. The merging strategy should also provide a time step higher than the minimal time step required in crash simulations.

2 0.6688E-03 0.2863E-03 FVBAG 666000001 0.0% 2.739 0.1415E-14 0.000 -0.8103E-19 0.000

** MONITORED VOLUME ID: ********TIME STEP: 0.2878E-03 FINITE VOLUME: 21940

** MONITORED VOLUME ID: ******** - FINITE VOLUME MESH UPDATE **

NUMBER OF FINITE VOLUMES : 30605

SUM VOLUME FINITE VOLUMES : 155386.459 (VOLUME AIRBA 155386.459 )

SUM AREA SURFACE POLYGONS : 227440.887 (AREA AIRBAG 227440.887 )A reasonable number of finite volume are needed and finite volume merging should not cause the number to drop immediately to one finite volume.

The finite volume time step in the /DT/FVMBAG card should be less than the initial finite volume time step output in Starter output. Merging parameter Cgmerg in /FVMBAG/MODIF should not be very high to provide smooth FV merging history.

** MONITORED VOLUME ID: 1 - FINITE VOLUME MESH UPDATE **

NUMBER OF FINITE VOLUMES : 1565

SUM VOLUME FINITE VOLUMES : 298121.912 (VOLUME AIRBA 298121.912)

SUM AREA SURFACE POLYGONS : 230093.158 (AREA AIRBAG 230093.158)44 0.1320 0.2865E-02 FVBAG 1 1.0% 7.222 0.1104 0.000 0.4265E-01 0.000

** MONVOL ID 1 FINITE VOLUME MESH UPDATE - LOOPING - NUMBER OF FINITE VOLUMES : 1564

** MONVOL ID 1 FINITE VOLUME MESH UPDATE - LOOPING - NUMBER OF FINITE VOLUMES : 1563

** MONITORED VOLUME ID: 1TIME STEP: 0.4293E-02 FINITE VOLUME: 396

The gas motion inside the airbag should be reviewed by contour plotting the animation output of the temperature and velocity of the gas. The motion should clearly develop from the inflator into the airbag volume and account for the airbag topology (internal walls, baffles, vent holes, etc.).

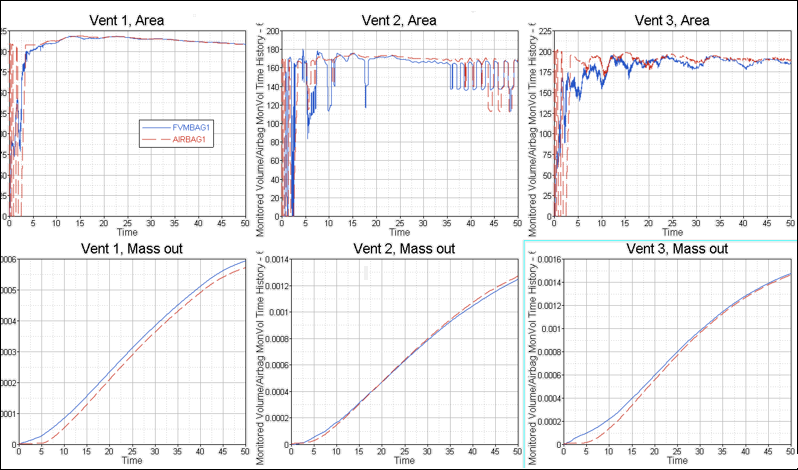

Figure 2. Comparison of airbag output for AIRBAG1 and FVMBAG1 simulations

Figure 3. Comparison of venting parameters for AIRBAG1 and FVMBAG1 simulations

The vent area and vent outflow should be plotted for each vent and controlled and compared to uniform pressure run.