RD-HWX-T: 1000 Tensile Test Setup

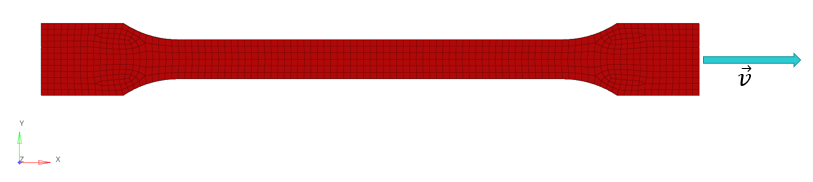

This tutorial demonstrates how to simulate an uniaxial tensile test using a standardized specimen with a defined cross-sectional area which is stretched until fracture.

Figure 1.

- Step1: Load the Radioss (Block) interface and load initial solver deck

- Step 2: Define material

- Step 3: Define property

- Step 4: Create rigid body

- Step 5: Create boundary conditions

- Step 6: Create imposed velocity

- Step 7: Create output (time history / anim)

- Step 8: Create Engine setup and export the model

- Step 9: Run the model using Compute Console

- Step 10: Post-process with HyperView and HyperGraph

Model Description

- UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa)

- Simulation time D01 [0 – 40.]

- At the right side, a constant velocity is applied = 1 mm/ms on -X direction.

- Tensile test object dimensions = 12 x 200 with a uniform thickness = 1.7 mm

- Material

- Value

- Initial density, [Rho_I]

- 2.7e-6Kg/mm3

- Young's modulus, [E]

- 60.4 GPa

- Poisson's ratio, [nu]

- 0.33

- Yield stress, [SIGMA_Y]

- 0.09026 GPa

- Ultimate tensile stress, [UTS]

- 0.175 GPa

- Engineering strain at UTS, [E_UTS]

- 0.24

- Failure plastic strain, [EPS_max]

- 0.75

Prerequisites

To run this simulation, you will need access to a licensed version of Radioss. You will need an internet connection to watch the video tutorials and download the files.