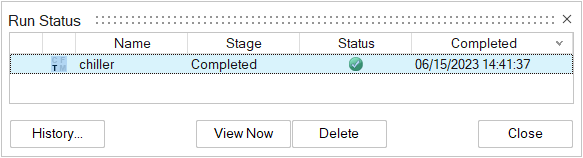

Tutorial: Adding a Chiller and Mold

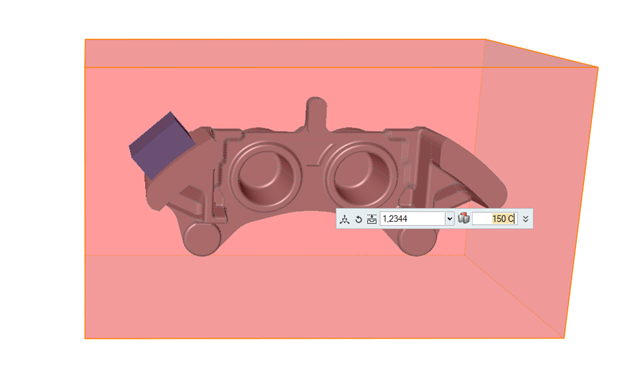

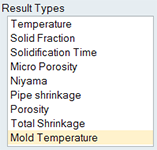

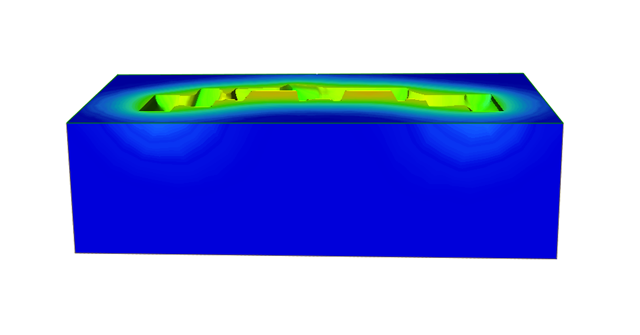

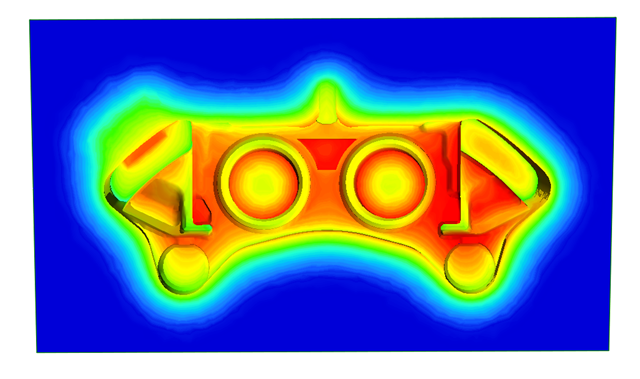

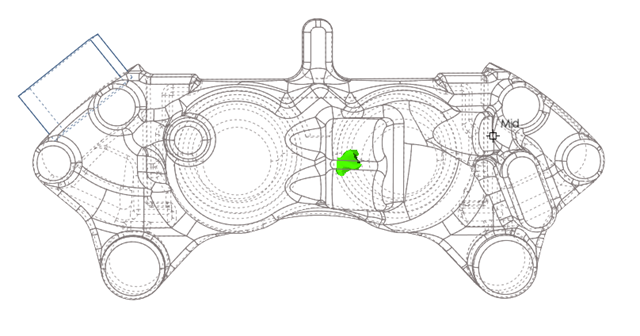

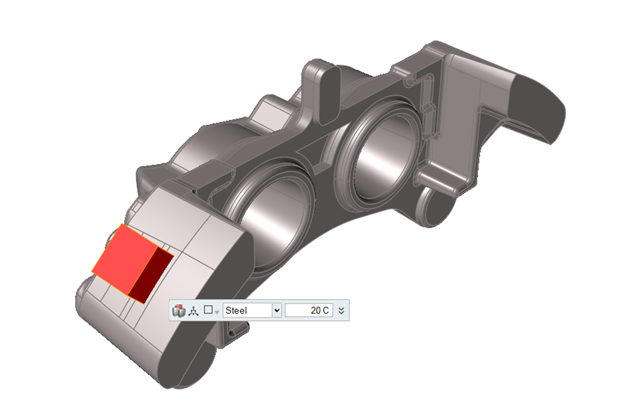

See how the two halves of a reflectionally symmetric part solidify when a chiller is added to one side.

In this exercise, you will learn how to analyze the effect a chiller has on casting.

Model file is available in the tutorial_models folder in the installation directory in Program Files\Altair\2022.3\InspireCast2022.3\tutorial_models\chiller.x_b.

Import Geometry

Designate a Casting Part

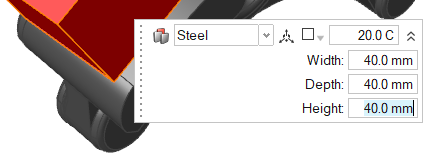

to enter dimensions of 40 mm for

the

to enter dimensions of 40 mm for

the