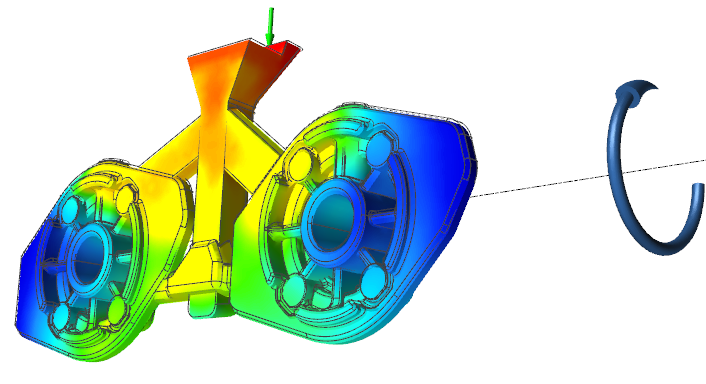

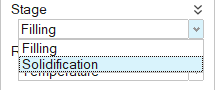

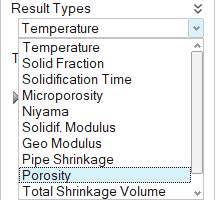

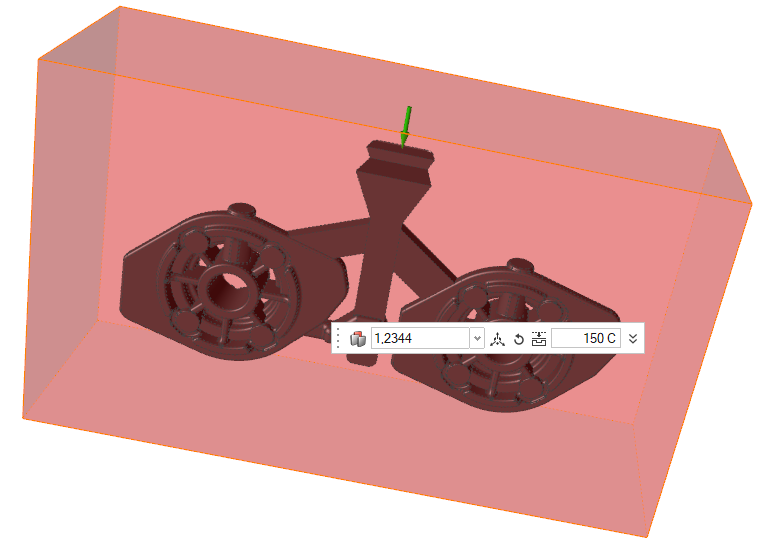

Tutorial: Gravity Tilt Pouring Casting

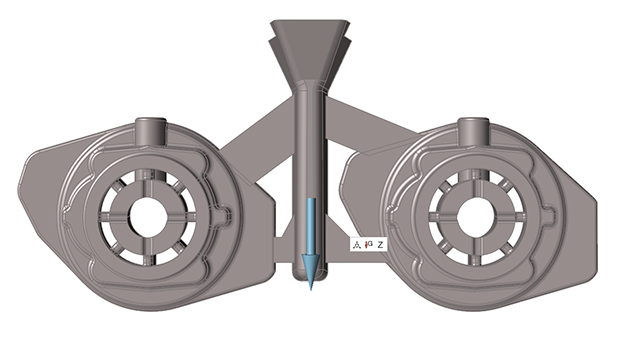

Step through setup and defining the rotation for a gravity tilt pouring casting simulation.

Model file is available in the tutorial_models folder in the installation directory in Program Files\Altair\2022.3\InspireCast2022.3\tutorial_models\Tilt-Pour.x_b.

Import Geometry

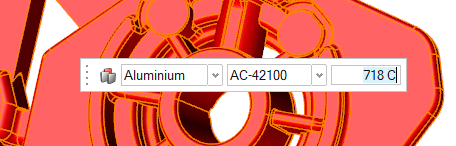

Designate a Casting Part

icon next

to the

icon next

to the

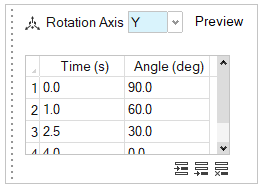

icon to add rows to the table.

icon to add rows to the table.