Allows for the study of fatigue performance of spot welds in structures.

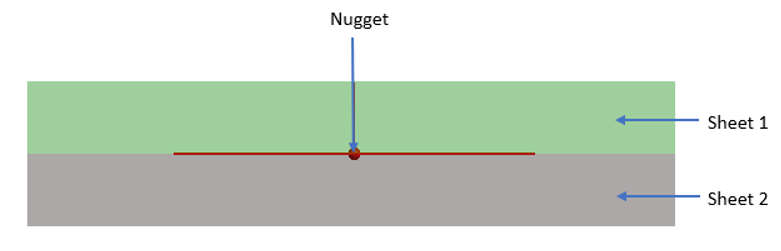

Currently, only stress-life (SN) based spot weld fatigue analysis is supported. The

spot weld location is defined by three attributes, sheet 1, sheet 2, and the nugget.

Figure 1. Spot Weld Fatigue

Implementation

Fatigue analysis for spot welds involves examining the weld at three distinct

locations, the sheets and nugget, and is based on a paper by Rupp et al. The

cross-sectional forces and moments at the nugget location are determined and used to

calculate corresponding stresses at the sheets and the nugget. These stresses are

then used to calculate Fatigue Damage using Rainflow counting and the SN

approach.

The following sections illustrate how stresses and subsequently damage are calculated

at each of the three locations.

Sheet Location (1 or 2)

Figure 2. Forces and Moments of Interest at Sheet Locations

Radial stresses are calculated at the sheet by considering forces and moments at the

nugget. The radial stresses

σ

(

θ

)

are calculated as a function of

θ

for each point in the load-time history as:

(1)

σ ( θ ) = −

σ

max

(

f

y

) cos θ −

σ

max

(

f

z

) sin θ + σ (

f

x

) +

σ

max

(

m

y

) sin θ −

σ

max

(

m

z

) cos θ

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4WdmNaai

ikaiabeI7aXjaacMcacqGH9aqpcqGHsislcqaHdpWCdaWgaaWcbaGa

ciyBaiaacggacaGG4baabeaakiaacIcacaWGMbWaaSbaaSqaaiaadM

haaeqaaOGaaiykaiGacogacaGGVbGaai4CaiabeI7aXjabgkHiTiab

eo8aZnaaBaaaleaaciGGTbGaaiyyaiaacIhaaeqaaOGaaiikaiaadA

gadaWgaaWcbaGaamOEaaqabaGccaGGPaGaci4CaiaacMgacaGGUbGa

eqiUdeNaey4kaSIaeq4WdmNaaiikaiaadAgadaWgaaWcbaGaamiEaa

qabaGccaGGPaGaey4kaSIaeq4Wdm3aaSbaaSqaaiGac2gacaGGHbGa

aiiEaaqabaGccaGGOaGaamyBamaaBaaaleaacaWG5baabeaakiaacM

caciGGZbGaaiyAaiaac6gacqaH4oqCcqGHsislcqaHdpWCdaWgaaWc

baGaciyBaiaacggacaGG4baabeaakiaacIcacaWGTbWaaSbaaSqaai

aadQhaaeqaaOGaaiykaiGacogacaGGVbGaai4CaiabeI7aXbaa@78E3@

Where,

(2)

σ

max

(

f

y

)

=

f

y

π

D

T

×

C

f

y

z

×

D

d

e

f

y

z

×

T

t

e

f

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiGac2gacaGGHbGaaiiEaaqabaGccaGGOaGaamOzamaaBaaa

leaacaWG5baabeaakiaacMcacqGH9aqpdaWcaaqaaiaadAgadaWgaa

WcbaGaamyEaaqabaaakeaacqaHapaCcaWGebGaamivaaaacaaMc8Ua

ey41aqRaaGPaVlaadoeadaWgaaWcbaGaamOzaiaadMhacaWG6baabe

aakiaaykW7cqGHxdaTcaaMc8UaamiramaaCaaaleqabaGaamizaiaa

dwgacaWGMbGaamyEaiaadQhaaaGccaaMc8Uaey41aqRaaGPaVlaads

fadaahaaWcbeqaaiaadshacaWGLbGaamOzaiaadMhacaWG6baaaaaa @63C6@

(3)

σ

max

(

f

z

)

=

f

z

π

D

T

×

C

f

y

z

×

D

d

e

f

y

z

×

T

t

e

f

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiGac2gacaGGHbGaaiiEaaqabaGccaGGOaGaamOzamaaBaaa

leaacaWG6baabeaakiaacMcacqGH9aqpdaWcaaqaaiaadAgadaWgaa

WcbaGaamOEaaqabaaakeaacqaHapaCcaWGebGaamivaaaacaaMc8Ua

ey41aqRaaGPaVlaadoeadaWgaaWcbaGaamOzaiaadMhacaWG6baabe

aakiaaykW7cqGHxdaTcaaMc8UaamiramaaCaaaleqabaGaamizaiaa

dwgacaWGMbGaamyEaiaadQhaaaGccaaMc8Uaey41aqRaaGPaVlaads

fadaahaaWcbeqaaiaadshacaWGLbGaamOzaiaadMhacaWG6baaaaaa @63C8@

(4)

σ

(

f

x

)

=

1.744

f

x

T

2

×

C

f

x

×

D

d

e

f

x

×

T

t

e

f

x

for

f

x

>

0.0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4WdmNaai

ikaiaadAgadaWgaaWcbaGaamiEaaqabaGccaGGPaGaeyypa0ZaaeWa

aeaadaWcaaqaaiaaigdacaGGUaGaaG4naiaaisdacaaI0aGaamOzam

aaBaaaleaacaWG4baabeaaaOqaaiaadsfadaahaaWcbeqaaiaaikda

aaaaaaGccaGLOaGaayzkaaGaaGPaVlabgEna0kaaykW7caWGdbWaaS

baaSqaaiaadAgacaWG4baabeaakiaaykW7cqGHxdaTcaaMc8Uaamir

amaaCaaaleqabaGaamizaiaadwgacaWGMbGaamiEaaaakiaaykW7cq

GHxdaTcaaMc8UaamivamaaCaaaleqabaGaamiDaiaadwgacaWGMbGa

amiEaaaakiaaywW7caqGMbGaae4BaiaabkhacaaMf8UaamOzamaaBa

aaleaacaWG4baabeaakiaaysW7cqGH+aGpcaaMe8UaaGimaiaac6ca

caaIWaaaaa@6FB5@

(5)

f

x

=

0.0

for

f

x

≥

0.0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaWaaeWaaeaaqa

aaaaaaaaWdbiaadAgadaWgaaWcbaGaamiEaaqabaaak8aacaGLOaGa

ayzkaaWdbiaabccacqGH9aqpcaqGGaGaaGimaiaac6cacaaIWaGaaG

zbVlaabAgacaqGVbGaaeOCaiaaywW7caWGMbWaaSbaaSqaaiaadIha

aeqaaOGaaGjbVlabgwMiZkaaysW7caaIWaGaaiOlaiaaicdaaaa@4D5B@

(6)

σ

max

(

m

y

)

=

1.872

m

y

D

T

2

×

C

m

y

z

×

D

d

e

m

y

z

×

T

t

e

m

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiGac2gacaGGHbGaaiiEaaqabaGccaGGOaGaamyBamaaBaaa

leaacaWG5baabeaakiaacMcacqGH9aqpdaqadaqaamaalaaabaGaaG

ymaiaac6cacaaI4aGaaG4naiaaikdacaWGTbWaaSbaaSqaaiaadMha

aeqaaaGcbaGaamiraiaadsfadaahaaWcbeqaaiaaikdaaaaaaaGcca

GLOaGaayzkaaGaaGPaVlabgEna0kaaykW7caWGdbWaaSbaaSqaaiaa

d2gacaWG5bGaamOEaaqabaGccaaMc8Uaey41aqRaaGPaVlaadseada

ahaaWcbeqaaiaadsgacaWGLbGaamyBaiaadMhacaWG6baaaOGaaGPa

VlabgEna0kaaykW7caWGubWaaWbaaSqabeaacaWG0bGaamyzaiaad2

gacaWG5bGaamOEaaaaaaa@6854@

(7)

σ

max

(

m

z

)

=

1.872

m

z

D

T

2

×

C

m

y

z

×

D

d

e

m

y

z

×

T

t

e

m

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aaS

baaSqaaiGac2gacaGGHbGaaiiEaaqabaGccaGGOaGaamyBamaaBaaa

leaacaWG6baabeaakiaacMcacqGH9aqpdaqadaqaamaalaaabaGaaG

ymaiaac6cacaaI4aGaaG4naiaaikdacaWGTbWaaSbaaSqaaiaadQha

aeqaaaGcbaGaamiraiaadsfadaahaaWcbeqaaiaaikdaaaaaaaGcca

GLOaGaayzkaaGaaGPaVlabgEna0kaaykW7caWGdbWaaSbaaSqaaiaa

d2gacaWG5bGaamOEaaqabaGccaaMc8Uaey41aqRaaGPaVlaadseada

ahaaWcbeqaaiaadsgacaWGLbGaamyBaiaadMhacaWG6baaaOGaaGPa

VlabgEna0kaaykW7caWGubWaaWbaaSqabeaacaWG0bGaamyzaiaad2

gacaWG5bGaamOEaaaaaaa@6856@

D

Diameter of the weld element

T

Thickness of the sheet under consideration for damage calculation

C

f

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGMbGaamyEaiaadQhaaeqaaaaa@39D0@

,

C

m

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGTbGaamyEaiaadQhaaeqaaaaa@39D7@

,

C

f

x

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGMbGaamiEaaqabaaaaa@38D0@

Scale factors

d

e

f

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamizaiaadw

gacaWGMbGaamyEaiaadQhaaaa@3AB0@

,

d

e

m

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamizaiaadw

gacaWGTbGaamyEaiaadQhaaaa@3AB7@

,

d

e

f

x

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamizaiaadw

gacaWGMbGaamiEaaaa@39B0@

Diameter exponents

t

e

f

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamiDaiaadw

gacaWGMbGaamyEaiaadQhaaaa@3AC0@

,

t

e

m

y

z

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamiDaiaadw

gacaWGTbGaamyEaiaadQhaaaa@3AC7@

,

t

e

f

x

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaWcbaGaamiDaiaadw

gacaWGMbGaamiEaaaa@39C0@

Thickness exponents

To be equivalent to the Rupp method:

C

f

y

z

=

1

,

d

e

f

y

z

=

0

,

t

e

f

y

z

=

0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGMbGaamyEaiaadQhaaeqaaOGaaGPaVlabg2da9iaaykW7

caaIXaGaaiilaiaaykW7caaMf8UaamizaiaadwgacaWGMbGaamyEai

aadQhacaaMc8Uaeyypa0JaaGPaVlaaicdacaGGSaGaaGzbVlaadsha

caWGLbGaamOzaiaadMhacaWG6bGaaGPaVlabg2da9iaaykW7caaIWa

aaaa@57E9@

C

m

y

z

=

0.6

,

d

e

m

y

z

=

0

,

t

e

m

y

z

=

0.5

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGTbGaamyEaiaadQhaaeqaaOGaaGPaVlabg2da9iaaykW7

caaIWaGaaiOlaiaaiAdacaGGSaGaaGPaVlaaywW7caWGKbGaamyzai

aad2gacaWG5bGaamOEaiaaykW7cqGH9aqpcaaMc8UaaGimaiaacYca

caaMf8UaamiDaiaadwgacaWGTbGaamyEaiaadQhacaaMc8Uaeyypa0

JaaGPaVlaaicdacaGGUaGaaGynaaaa@5AE0@

C

f x

= 0.6 , d e f x = 0 , t e f x = 0.5

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaWGMbGaamiEaaqabaGccaaMc8Uaeyypa0JaaGPaVlaaicda

caGGUaGaaGOnaiaacYcacaaMc8UaaGzbVlaadsgacaWGLbGaamOzai

aadIhacaaMc8Uaeyypa0JaaGPaVlaaicdacaGGSaGaaGzbVlaadsha

caWGLbGaamOzaiaadIhacaaMc8Uaeyypa0JaaGPaVlaaicdacaGGUa

GaaGynaaaa@57CB@

The equivalent radial stresses are calculated at intervals of

θ

(Default =18 degrees). The value of

θ

can be modified by varying the Number of angles field in the spot weld solution

settings. Subsequently, Rainflow cycle counting is used to calculate fatigue life

and damage at each angle (

θ

). The worst damage value is then picked for output. A

similar approach is conducted for the other sheet.

Nugget Location

Figure 3. Forces and Moments of Interest at Nugget Cross-Section

The absolute maximum principal stresses are calculated using the shear stress and

bending stress of the beam element as a function of

θ

for each point in the load-time history as:

(8)

τ

(

θ

)

=

τ

max

(

f

y

)

sin

θ

+

τ

max

(

f

z

)

cos

θ

(9)

σ ( θ ) = σ (

f

x

) +

σ

max

(

m

y

) sin θ −

σ

max

(

m

z

) cos θ

MathType@MTEF@5@5@+=

feaahqart1ev3aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4WdmNaai

ikaiabeI7aXjaacMcacqGH9aqpcqaHdpWCcaGGOaGaamOzamaaBaaa

leaacaWG4baabeaakiaacMcacqGHRaWkcqaHdpWCdaWgaaWcbaGaci

yBaiaacggacaGG4baabeaakiaacIcacaWGTbWaaSbaaSqaaiaadMha

aeqaaOGaaiykaiGacohacaGGPbGaaiOBaiabeI7aXjabgkHiTiabeo

8aZnaaBaaaleaaciGGTbGaaiyyaiaacIhaaeqaaOGaaiikaiaad2ga

daWgaaWcbaGaamOEaaqabaGccaGGPaGaci4yaiaac+gacaGGZbGaeq

iUdehaaa@5C85@

Where,

(10)

τ

max

(

f

y

)

=

16

f

y

3

π

D

2

(11)

τ

max

(

f

z

)

=

16

f

z

3

π

D

2

(12)

σ

f

x

=

4

f

x

π

D

2

for

f

x

>

0.0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aae

WaaeaacaWGMbWaaSbaaSqaaiaadIhaaeqaaaGccaGLOaGaayzkaaGa

aGjbVlabg2da9iaaysW7daWcaaqaaiaaisdacaWGMbWaaSbaaSqaai

aadIhaaeqaaaGcbaGaeqiWdaNaamiramaaCaaaleqabaGaaGOmaaaa

aaGccaaMf8UaaeOzaiaab+gacaqGYbGaaGzbVlaadAgadaWgaaWcba

GaamiEaaqabaGccaaMc8UaeyOpa4JaaGPaVlaaicdacaGGUaGaaGim

aaaa@5430@

(13)

σ

f

x

=

0.0

for

f

x

≤

0.0

MathType@MTEF@5@5@+=

feaahqart1ev3aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeq4Wdm3aae

WaaeaacaWGMbWaaSbaaSqaaiaadIhaaeqaaaGccaGLOaGaayzkaaGa

aGjbVlabg2da9iaaysW7caaIWaGaaiOlaiaaicdacaaMf8UaaeOzai

aab+gacaqGYbGaaGzbVlaadAgadaWgaaWcbaGaamiEaaqabaGccaaM

c8UaeyizImQaaGPaVlaaicdacaGGUaGaaGimaaaa@509E@

(14)

σ

max

(

m

y

)

=

32

m

y

π

D

3

(15)

σ

max

(

m

z

)

=

32

m

z

π

D

3

D

Diameter of the weld element

T

Thickness of the sheet under consideration for damage calculation

The equivalent maximum absolute principal stresses are calculated for each

θ

from

τ

(

θ

)

and

σ

(

θ

)

. These stresses are used for subsequent fatigue

analysis. Rainflow cycle counting is used to calculate fatigue life and damage at

each angle (

θ

). The worst damage value is then picked for output.