Quality Index Calculations

The Quality Index value is a function of twelve criteria with user-defined weight factors. Each criterion has five rating levels.

- element Q.I.

- (weighted average of penalties that pass) + (weighted sum of penalties that fail)

- criteria Q.I.

- (weighted average of penalties of elements that pass) + (weighted sum of penalties of elements that fail)

- compound Q.I

- (weighted average of criteria Q.I. that pass) + (weighted sum of criteria Q.I. that fail)

All of this means that higher compound Q.I. values indicate worse quality.

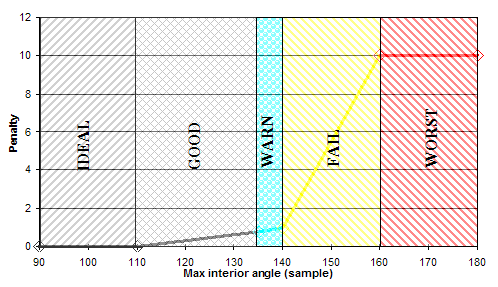

Figure 1. Criterion Levels

- Ideal

- The absolute best/ideal value that an element can achieve. For example, an ideal element would have an aspect ratio of 1.0, warpage of 0.0, jacobian of 1.0, and so on. Some criteria may not have an ideal, for example the ideal minimum element size is the same as average element size. Similarly, for simulations that require all triangular mesh, "% of trias" is not applicable. Thus, the ideal "% of trias" depends on the analysis type, and should be set by you. Elements that fall in this level are drawn in their default color, not highlighted. Ideal elements have no penalty assigned to them.

- Good

- This level is slightly worse than ideal but is still considered good for the required analysis. All elements whose criteria are equal to or better than this level are considered good and no penalty is assigned to them. You set all the good level thresholds. Elements that fall in this level, between good and warn, are drawn in their default color, not highlighted. The elements that fall between good and warn are assigned a penalty between 0-0.79.

- Warn

- An intermediate level between good and fail. This level is used to highlight the elements that have not failed the criteria but are close to it. Engineering Solutions sets these values at 80 percent between good and fail levels. The elements that are in this level, that is, falling between warn and fail, are drawn in cyan by default and are assigned a penalty value between 0.8 – 0.99.

- Fail

- Determines the elements that are considered to be unacceptable for analysis, thus failed. It is recommended that you fix these elements before performing the analysis. You can specify the fail levels. All the elements that fail are given a penalty greater than 1.0. The penalty value is calculated depending on the severity of the failure. The elements that have failed, between fail and worst, are drawn in yellow by default and are given a penalty value between 1.0-10.0. Therefore, elements that passed all criteria have a penalty less than 1.0.

- Worst

- Highlights elements that failed the criteria by a large margin, and which require immediate attention. The worst levels are set by Engineering Solutions as a factor of good and fail values. The elements that fall in and beyond this worst level are drawn in red and given a flat penalty value of 10.0.