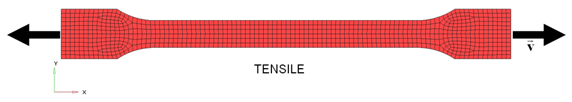

RD-T: 3000 Tensile Test Setup

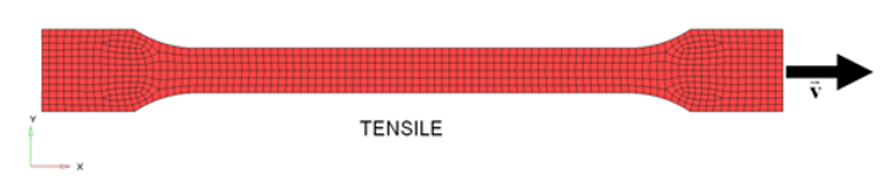

This tutorial demonstrates how to simulate a uniaxial tensile test using a quarter size mesh with symmetric boundary conditions.

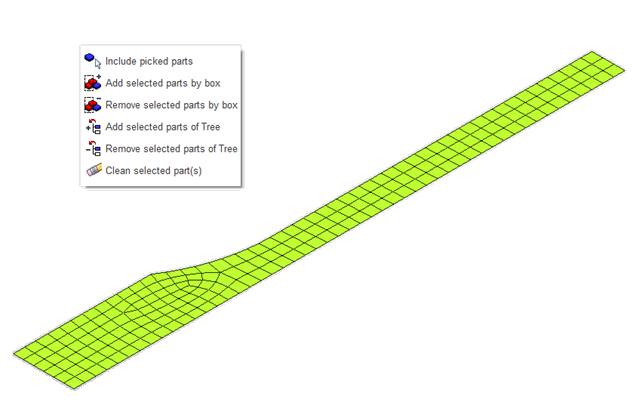

図 1.

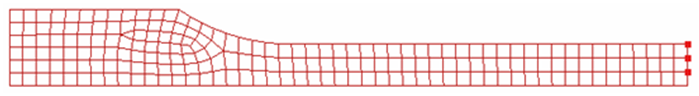

図 2.

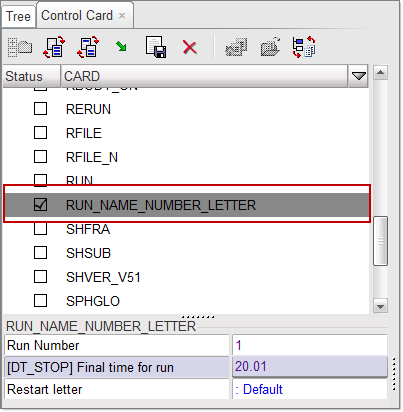

- UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa)

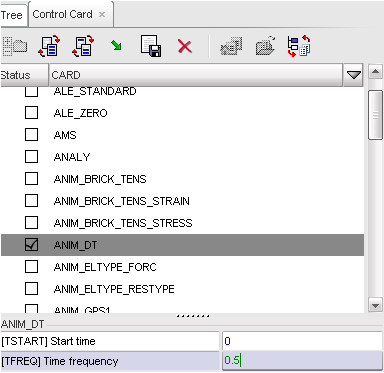

- Simulation time Rootname_0001.rad [0 - 10.]

- Boundary Conditions:

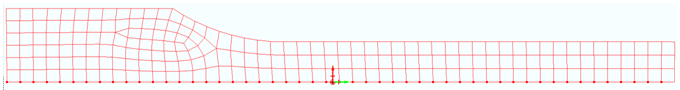

- The 3 upper right nodes (TX, RY, and RZ)

- A symmetry boundary condition on all bottom nodes (TY, RX, and RZ)

- At the left side is applied a constant velocity = 1 mm/ms on -X direction.

- Tensile test object dimensions = 11 x 100 with a uniform thickness = 1.7 mm

Johnson-Cook Elastic Plastic Material /MAT/PLAS_JOHNS (Aluminum 6063 T7)

[Rho_I] Initial density = 2.7e-6 Kg/mm3

[E] Young's modulus = 60.4 GPa

[nu] Poisson's ratio = 0.33

[a] Plasticity yield stress = 0.09026 GPa

[b] Plasticity hardening parameter = 0.22313 GPa

[n] Plasticity hardening exponent = 0.374618

[EPS_p_max] Failure plastic strain = 0.75

[SIG_max0] Plasticity maximum stress = 0.175 GPa

Model Files

必要なモデルファイルのダウンロードについては、モデルファイルへのアクセスを参照してください。

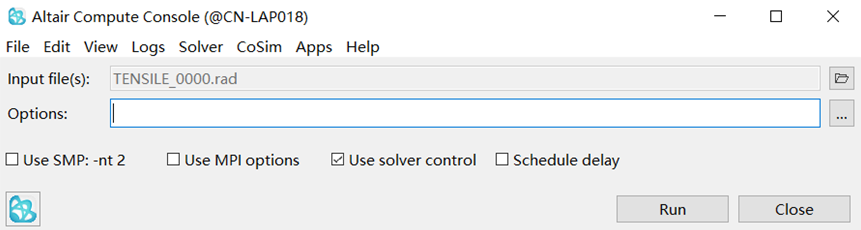

Input file for this tutorial: TENSILE_0000.rad

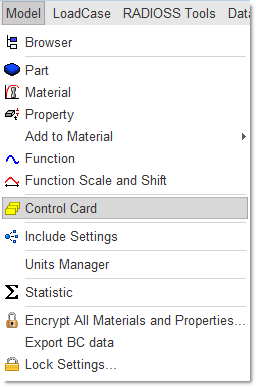

Start HyperCrash

- Open HyperCrash.

- Set the User profile to RadiossV2022 and the Unit system to kN mm ms.kg.

- Set User Interface style as New.

- Set your working directory to where the downloaded file is located.

- Click Run.

- Click .

- In the input window, select TENSILE.rad.

- Click OK.

Create and Assign a Material

Create and Assign a Property

- From the menu bar, select .

- In the Property tab, right-click and select .

- For Title, enter Pshell.

- For Shell Thickness, enter 1.7.

-

In the bottom of the property window, right-click in the

Support entry box and select the Include

picked parts icon

.

.

- Select the part in the モデリングウィンドウ.

- Right-click to validate the selection.

- Click .

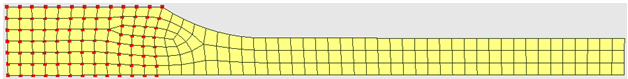

Define Boundary Conditions Representing Symmetry

Define Imposed Velocity

Define a Time History Node

Export the Model

Open Compute Console from the Windows Start Menu

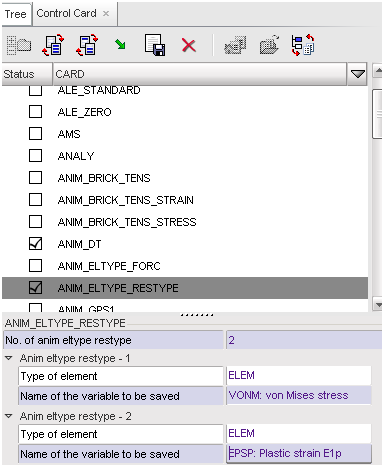

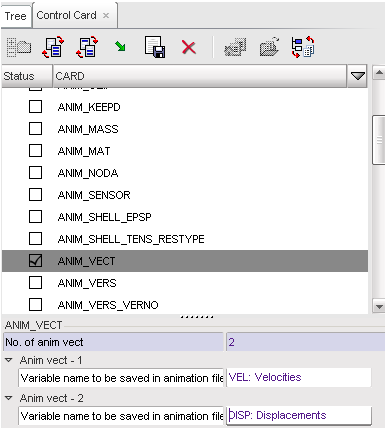

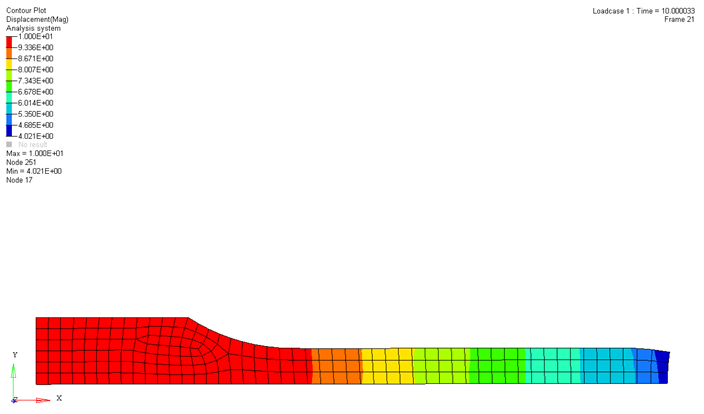

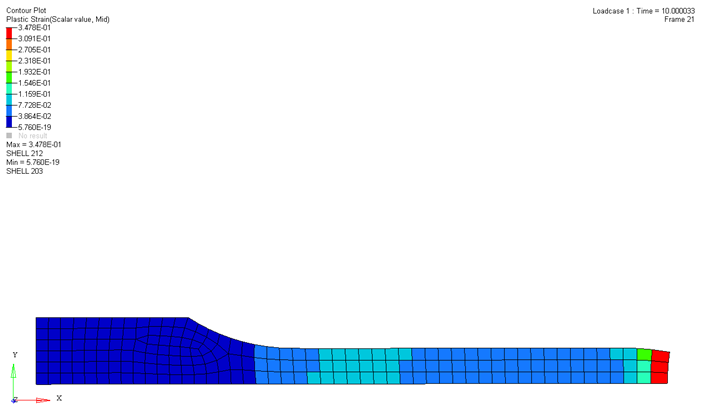

Expected Results

図 16. Total Displacement Contour (mm)

図 17. Plastic Strain Contour

to select the

nodes in the

to select the

nodes in the

, to select the nodes in the

, to select the nodes in the

to

add a new row.

to

add a new row.