RD-T: 3030 Buckling of a Tube Using Half Tube Mesh

This tutorial simulates buckling of a tube using half tube mesh with symmetric boundary conditions.

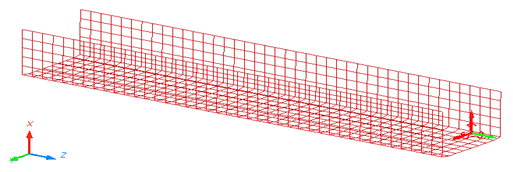

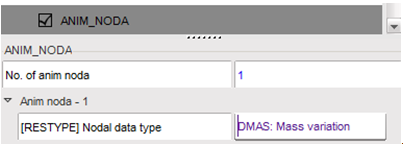

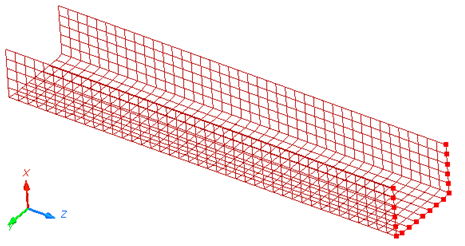

図 1. Model

The model description is as follows:

- UNITS: Length (mm), Time (ms), Mass (kg), Force (kN) and Stress (GPa)

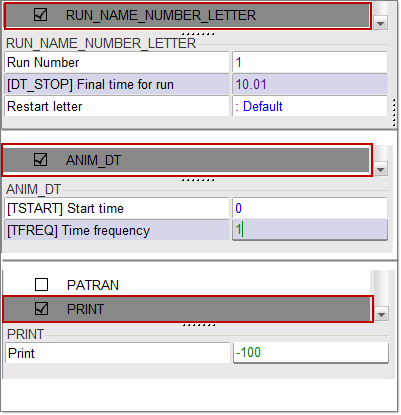

- Simulation time: Engine [0 - 10 ms]

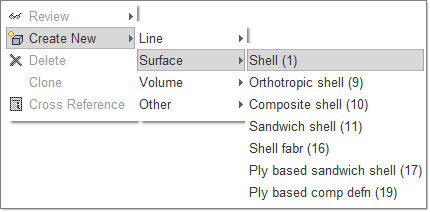

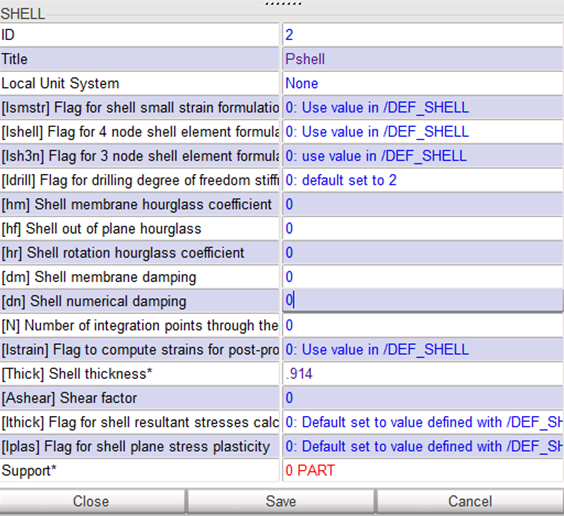

- The tube thickness is 0.914 mm.

- An imposed velocity of 13.3 mm/ms (~30 MPH) is applied to the right end of the tube

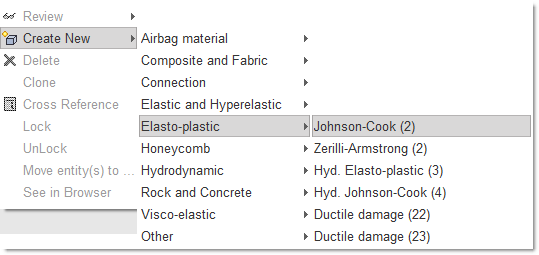

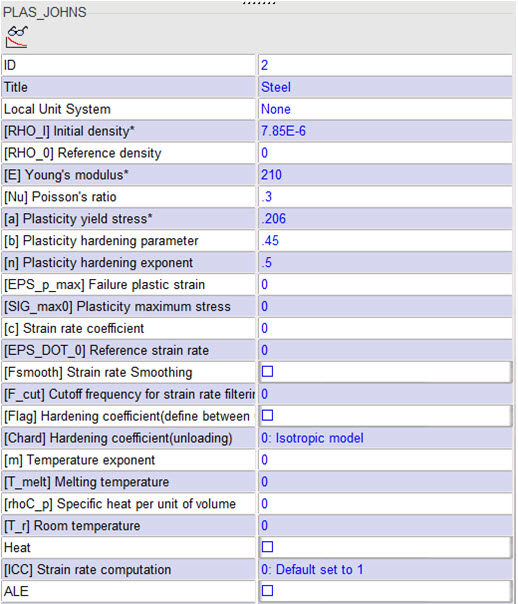

- Elasto plastic material using Johnson-Cook law /MAT/PLAS_JOHNS (STEEL).

[Rho_Initial] Initial density = 7.85e-6 Kg/mm3

[E] Young's modulus = 210 GPa

[nu] Poisson coefficient = 0.3

[a] Yield Stress = 0.206 GPa

[b] Hardening Parameter = 0.450 GPa

[n] Hardening Exponent = 0.5

Model Files

必要なモデルファイルのダウンロードについては、モデルファイルへのアクセスを参照してください。

Input file for this tutorial: BOXTUBE_0000.rad

Start HyperCrash

- Open HyperCrash.

- Set the User profile to RadiossV2022 and the Unit system to kN mm ms.kg.

- Set User Interface style as New.

- Set your working directory to where the downloaded file is located.

- Click Run.

- Click .

- In the input window, select BOXTUBE_0000.rad.

- Click OK.

Create and Assign a Material

Create and Assign a Property

Define the Rigid Body

Define Boundary Conditions

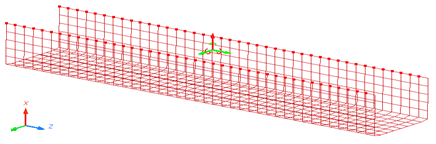

Define Boundary Conditions Representing Symmetry

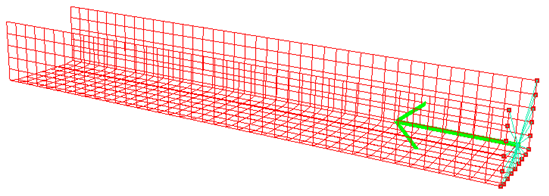

Define the Imposed Velocity

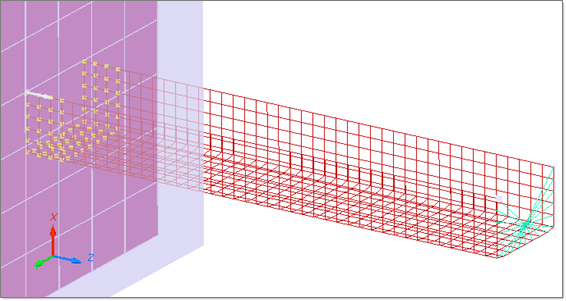

Define a Rigid Wall

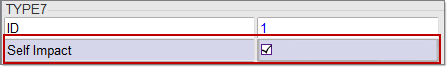

Create a Self Contact for the Tube

Export the Model

Open Compute Console from the Windows Start Menu

図 17.

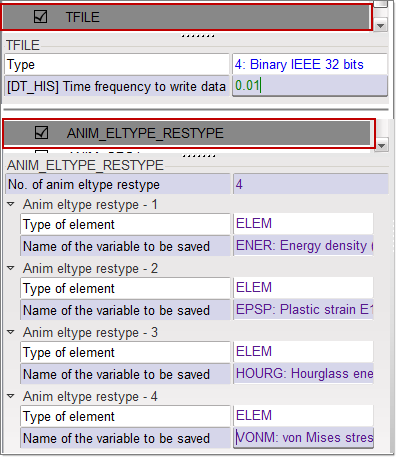

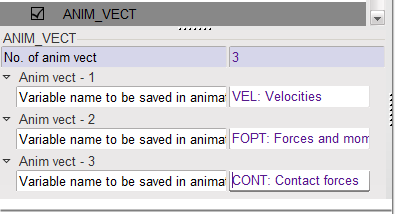

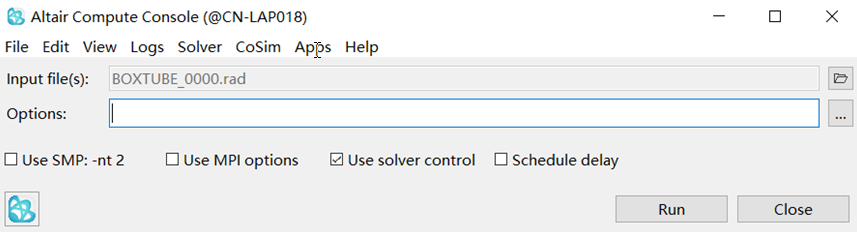

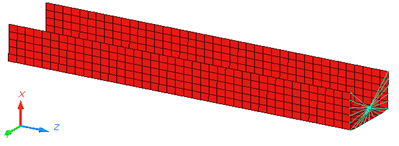

Review the Results

図 18.

and select boxtube

in the

and select boxtube

in the

to select the nodes in the

to select the nodes in the

in the toolbar, and select the rigid body main node

in the

in the toolbar, and select the rigid body main node

in the