/PROP/TYPE45 (KJOINT2)

Block Format Keyword KJOINT2 is a penalty connection used to model joint connections between rigid or deformable bodies.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /PROP/TYPE45/prop_ID/unit_ID or /PROP/KJOINT2/prop_ID/unit_ID | |||||||||

| prop_title | |||||||||

| Type | Kn | ScF | Cr | sens_ID | Skew_ID1 | Skew_ID2 | |||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Kti | fct_Kti | SDi- | SDi+ | Icomb_ti | |||||

| Ct | fct_Cti | ||||||||

| Kfxi | FFi | fct_FFi | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Kri | fct_Kri | SAi- | SAi+ | Icomb_ri | |||||

| Cri | fct_Cri | ||||||||

| Kfri | FMi | fct_FMi | |||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| prop_ID | Property

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit Identifier. (Integer, maximum 10 digits) |

|

| prop_title | Property

title. (Character, maximum 100 characters) |

|

| Type | Joint type (Joint Types List).

(Integer) |

|

| Kn | Stiffness for blocked DOF.

4

Default = 0.0 (Real) |

|

| ScF | Scale factor for

Kn. 4 If Kn = 0: Scale factor on both translational and rotational stiffness. Default = 1.0 (Real) If Kn > 0: Scale factor on only the rotational stiffness. Default = 10.0 (Real) |

|

| Cr | Critical damping factor.

4 Default = 0.05 (Real) |

|

| sens_ID | Sensor identifier. 3 (Integer) |

|

| Skew_ID1 | First skew system identifier . 4 (Integer) |

|

| Skew_ID2 | Second skew

system identifier. 4

(Integer) |

|

| Kti | Translational stiffness of

non-blocked DOF. 4 If fct_Kti = 0: Constant translational stiffness value. If fct_Kti > 0: Translational stiffness scale factor. Default =1.0 (Real) |

or |

| fct_Kti | Translational force versus

displacement function identifier of non-blocked

DOF. (Integer) |

|

| SDi-, SDi+ | Negative and Positive

stopping displacement. 8 Default = 0.0 (Real) |

|

| Cti | Translational viscosity

coefficient of non-blocked DOF. 4 If fct_Cti = 0: Constant translational viscosity. If fct_Cti > 0: Translational viscosity scale factor. Default = 1.0 (Real) |

or |

| fct_Cti | Translational viscous

force versus displacement rate function

identifier. (Integer) |

|

| Kfti | Elastic stiffness for

friction and stop displacement. 5 Default = 0.0 (Real) |

|

| FFi | Frictional force value.

5

Default = 0.0 (Real) |

|

| fct_FFi | Frictional force versus

displacement function identifier. (Integer) |

|

| Icomb_ti | Combining stop

displacements flag. 10

(Integer) |

|

| Kri | Rotational stiffness

coefficient of non-blocked DOF. 4 If fct_Kri = 0: Constant rotational stiffness value. If fct_Kri > 0: Rotational stiffness scale factor. Default = 1.0 (Real) |

or |

| fct_Kri | Rotational moment versus

rotational angle function identifier. (Integer) |

|

| SAi-, SAi+ | Positive and Negative

stopping angles in radians. 8 Default = 0.0 (Real) |

|

| Cri | Rotational viscosity

coefficient of non-blocked DOF. If fct_Cri = 0: Constant rotational viscosity value. If fct_Cri > 0: Rotational viscosity scale factor. Default = 1.0 (Real) |

or |

| fct_Cri | Rotational viscosity

moment versus rotational angle rate function

identifier. (Integer) |

|

| Kfri | Elastic stiffness per

radian unit for friction and stop angle. 5 Default = 0.0 (Real) |

|

| FMi | Frictional moment value of

non-blocked DOF. 5 If fct_FMi = 0: Constant frictional moment value. If fct_FMi > 0: Frictional moment scale factor. Default = 0.0 (Real) |

|

| fct_FMi | Frictional moment versus

rotational angle function identifier. (Integer) |

|

| Icomb_ri | Combining stop angles.

10

(Integer) |

Joint Types List

| Type No. | Joint Type | dx | dy | dz | |||

|---|---|---|---|---|---|---|---|

| 1 | Spherical | x | x | x | 0 | 0 | 0 |

| 2 | Revolute | x | x | x | 0 | x | x |

| 3 | Cylindrical | 0 | x | x | 0 | x | x |

| 4 | Planar | x | 0 | 0 | 0 | x | x |

| 5 | Universal | x | x | x | x | 0 | 0 |

| 6 | Translational | 0 | x | x | x | x | x |

| 7 | Oldham | x | 0 | 0 | x | x | x |

| 8 | Rigid | x | x | x | x | x | x |

| 9 | Free | 0 | 0 | 0 | 0 | 0 | 0 |

- x

- Denotes a blocked DOF

- 0

- Denotes a free (user-defined) DOF

Example (Rotational)

#RADIOSS STARTER

/UNIT/2

unit for prop

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE45/2/2

Revolute

### - Define angle limit < 0.52rad

### - And define friction moment 100GPa to block angle (if it reached the limit)

# Type KN SCF CR SENSORID

2 0 0 0 0

# KR1Func_ID_Kr SA1- SA1+ Icomb_r1

0 0 0 .52 0

# CR1Func_ID_Cr

0 0

# KFR1 FM1 FCT_FM1

0 100 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATAExample (Translational)

#RADIOSS STARTER

/UNIT/2

unit for prop

kg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/TYPE45/12/2

Translational

### - define displacement limit: -100mm ~ 100 mm

# Type KN SCF CR SENSORID

6 0 0 .2 0

# KX1Func_ID_Kx SD1- SD1+ Icomb_t1

0 0 -100 100 0

# CX1Func_ID_Cx

0 0

# KFX1 FF1 FCT_FF1

1000 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATAComments

- The KJOINT2 spring is typically used to connect rigid bodies, but can also be used to connect nodes of deformable elements. When connecting nodes of deformable elements, the moment is not transferred if the node of the element does not have any rotatinal degees of freedom (DOF). This includes the following cases: all rotational DOF for nodes of solid and truss element, the drilling DOF of shell elements with the shell property Idril=2 (default), and some DOF for nodes of beam and spring elements.

- Spring element:

- The identifier must be unique in each element family, but it is advised to have a unique element identifier in the global model for each element type.

- More than one spring block can be used to define a part.

- Spring DOF:

- Joint properties are defined in a local coordinate system of the joint element.

- The total number of joint DOF computed in the local coordinate system

frame is six:

- Blocked and free DOF are distinguished for each joint type.

- The blocked DOF are characterized by a constant stiffness. By default, if no stiffness value is entered, the value of the stiffness is automatically computed to preserve the time step.

- The translational and rotational DOF are defined as:

(1) Where, and are total displacements of two joint nodes in the local coordinate system.(2) Where, and are total relative rotations of two connected body axes, with respect to the local coordinate system of the joint.

- If sens_ID is defined, then the joint becomes fully blocked (all degrees of freedom) when the sensor is activated.

- Forces and moments

calculation:

- The force in direction

is computed as:Linear spring:

(3) : translational stiffness

: translational viscosity

Nonlinear spring:(4) - The moment in

direction is computed as:Linear spring:

(5) : rotational stiffness ( )

: rotational viscosity ( )

Nonlinear spring:(6) - The joint length may be, but is not necessarily equal to 0. It is recommended to use a 0 length spring to define a spherical joint or a universal joint.

- To satisfy the global balance of moments in a general case, correction

terms in the rotational DOF are calculated as:

(7) (8) (9) Joints do not have user-defined mass or inertia, so the nodal time step is always used. The nodal time step is based on entities that the joint connects. If attached to a main node of a rigid body, the rigid body time step is used. If attached to the nodes of a deformable element, the nodal time is calculated based on the deformable element.

- The force in direction

is computed as:

- Stiffness of spring

- Coefficients and are used as constant stiffness, if there are no user-defined functions. If a function is defined, the corresponding stiffness coefficient becomes a scale factor for the function.

- If Kn = 0, the blocking stiffness is automatically computed at the beginning of the computation for both translational and rotational blocked DOF, in order to preserve the time step. These values are also selected according to the model physics and must be higher than the stiffness of the neighboring elements.

- If Kn = 0, then Scf is a scaling factor applied to both translational and rotational blocking stiffness. If Kn > 0, then Scf is applied only on blocking rotational stiffness. This parameter can be used to manually adjust the blocking stiffness in rotation.

- Viscosity of spring

- Coefficients and are used as linear viscosity coefficients, if there are no user-defined functions. If a function is defined, the corresponding coefficient becomes a scale factor for the function.

- There are two ways to introduce viscous damping:

- Defining a critical damping (for blocked DOF only):

Viscous damping is defined in terms of the critical damping factor. The critical damping coefficient is calculated using the blocking stiffness value of the element and the reduced mass (half of the harmonic mean of mass of the connected nodes). The same critical damping is applied to all blocked DOF.

- User-defined constant or nonlinear damping:

It is possible to define independent damping parameters for each free DOF.

For more information about stiffness and damping, refer to Spring Joint TYPE45 (/PROP/KJOINT2) in the User Guide.

- Defining a critical damping (for blocked DOF only):

- Friction

- Friction is not activated, if Kfti or Kfri are not defined.

- FFi and FMi are used as constant friction force and moment, if there are no user defined functions. If the friction function number is not 0, FMi and FFi become a scale factor for the functions (default = 1.0).

- Spring limit

- If a non-zero value is specified for SDi- or SDi+, then an additional penalty force is applied to prevent the displacement exceeding SDi+ for positive displacement and SDi- for negative displacement. This penalty force is computed using Kfti.

- If a non-zero value is specified for SAi- or SAi+, then an additional penalty moment is applied to prevent the angle exceeding SAi+ for positive rotation or SAi- for negative rotation. This penalty moment is computed using Kfri

- Skew of spring

- If Skew_ID1 is defined, the initial local coordinate system is defined by Skew_ID1. If Skew_ID1 = 0, the local coordinate system is computed according to the additional nodes of the spring. Refer to /SPRING for more information.

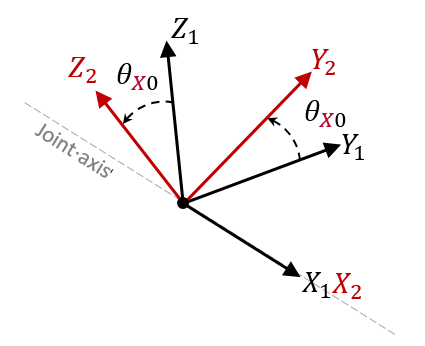

- If Skew_ID2 is defined, rotation angles of

the joint are initialized according the rotation between Skew_ID1 and

Skew_ID2.

Values of the initial angles can be check in the Starter output file.

For revolute (TYPE2), cylindrical (TYPE3) and planar (TYPE4) joints only

can be initialized. The first axis of

Skew_ID1 and

Skew_ID2 must

be parallel.

Figure 1. Computation of Initial Rotation Angle for Revolute Joint (TYPE2) - If Skew_ID2 is non-zero and Skew_ID1 =0, then Skew_ID1 is the global coordinate system.

- The local coordinate system orientation is updated according to node_ID1 (/SPRING) rotation.

- Combined stop

displacements/angles:

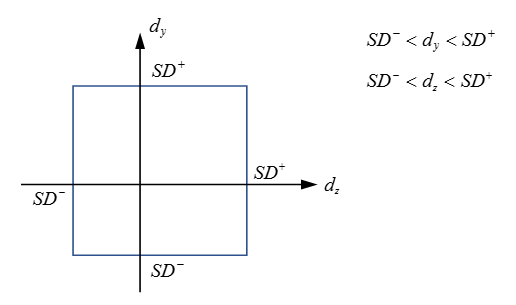

- If Icomb_ti = 0: the stop displacements are independent (default) as shown in Figure 2. Stop displacement will be checked separately in each direction.

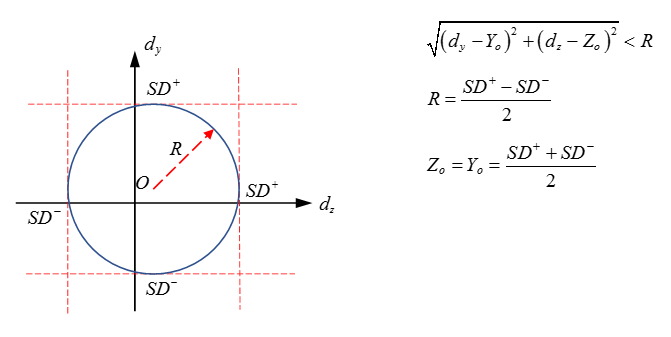

- If Icomb_ti = 1: the stop displacements of all the free translational DOF are combined. The stopping criteria is no longer applied on the displacement but on the normal of the combined displacements see Figure 3.

- 2 or 3 stop displacements can be combined

- If stop displacements are combined, the same value of SDi- and SDi+ must be used for each DOF.

- The above descriptions for stop displacements also apply for stop angles

defined using

Icomb_ri.

Figure 2. Planar Joint with Independent Stop Displacements, Icomb_ti=0

Figure 3. Planar Joint with 2 Combined Stopping Displacements, Icomb_ti=1