Stiffener

Check rules of stiffener.

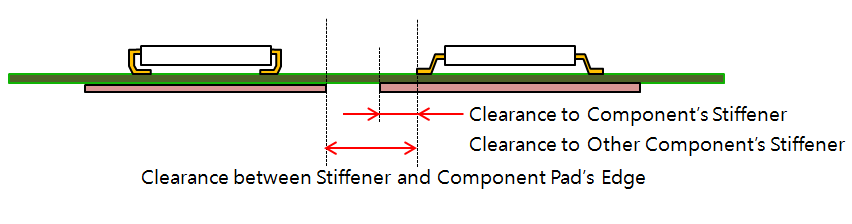

Components disposed on FPCB use the reinforcement plate, stiffener, in order to compensate for the thickness of the component or to protect the component as safe in SMT process.

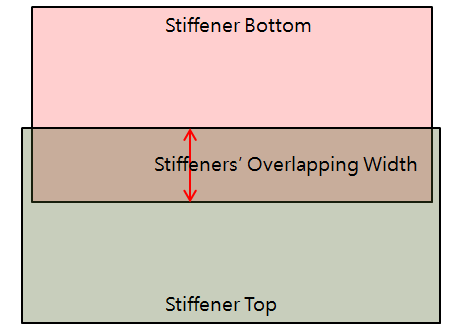

Stiffener Layer Definition

Define stiffener layer.

- For Stiffener Top Layer, select the stiffener top layer from layer list.

- For Stiffener Bottom Layer, select the stiffener bottom layer from layer list.

Target Component Definition

Define target components.

Checking

Define checking items.

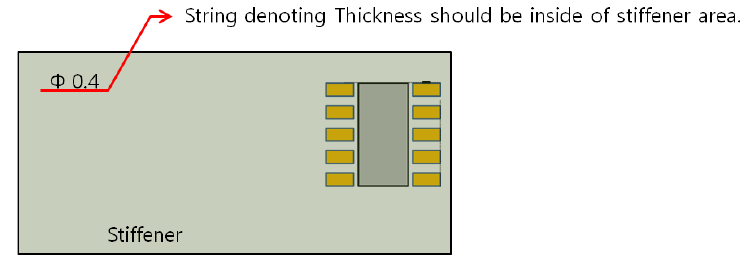

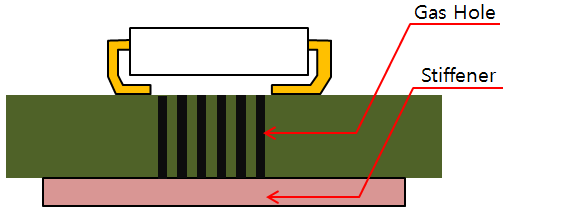

Gas Hole Stiffener

If there are gas-holes under components, you can make rules for gas holes.

Figure 5.

- For Gas Hole Layer Selection, define gas-hole layer by selecting layer from layer list.

- Select Minimum Gas Hole Size, set minimum gas hole size.

- Select Check Existence of Gas Hole in Stiffener to check if there are gas hole in stiffener area.

- Select Clearance between Gas Hole and Stiffener to set the clearance value between gas hole and stiffener.