/MAT/LAW43 (HILL_TAB)

Block Format Keyword This law describes the Hill orthotropic material and is applicable only to shell elements. This law differs from LAW32 (HILL) only in the input of yield stress (here it is defined by a user function).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW43/mat_ID/unit_ID or /MAT/HILL_TAB/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| fct_IDE | Einf | CE | |||||||

| r00 | r45 | r90 | Chard | Iyield0 | |||||

| Fcut | Fsmooth | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDi | Fscalei | ||||||||

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material title. (Character, maximum 100 characters) |

|

| Initial density. (Real) |

||

| E | Young's modulus. (Real) |

|

| Poisson's ratio. (Real) |

||

| fct_IDE | Function identifier for the scale factor

of Young's modulus, when Young's modulus is function of the plastic strain. 12 Default = 0: in this case the evolution of Young's modulus depends on Einf and CE. (Integer) |

|

| Einf | Saturated Young's modulus for infinitive

plastic strain. (Real) |

|

| CE | Parameter for Young's modulus evolution.

12 (Real) |

|

| r00 | Lankford parameter 0 degree. 3 Default = 1.0 (Real) |

|

| r45 | Lankford parameter 45 degrees. Default = 1.0 (Real) |

|

| r90 | Lankford parameter 90 degrees. Default = 1.0 (Real) |

|

| Chard | Hardening coefficient.

(Real) |

|

| Iyield0 | Yield stress flag.

(Integer) |

|

| Failure plastic strain. Default = 1.0 × 1030 (Real) |

||

| Tensile failure strain at which stress

starts to reduce. Default = 1.0 × 1030 (Real) |

||

| Maximum tensile failure strain at which

the stress in element is set to zero. Default = 2.0 × 1030 (Real) |

||

| Fcut | Cutoff frequency for strain rate

filtering. (Real) |

|

| Fsmooth | Smooth strain rate option flag.

(Integer) |

|

| fct_IDi | Plasticity curves

.ith function identifier. (Integer) |

|

| Fscalei | Scale factor for

ith function. Default set to 1.0 (Real) |

|

| Strain rate for

ith function. (Real) |

Example (Metal)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/HILL_TAB/1/1

metal

# RHO_I

7.8E-09

# E NU

206000 .3

#FUNCT_IDE EINF CE

0 0 0

# r00 r45 r90 C_hard Iyield0

1.73 1.34 2.24 0 0

# EPSP_max EPS_t1 EPS_m Fcut Fsmooth

0 0 0 15000 1

# func_IDi Fscale_i EPS_dot_i

5 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 3. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/5

metal

# X Y

0 260

.002 270

.005 280

.01 297

.02 322

.05 370

.1 422

.15 457

.2 485

.3 528

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- This material law must be used with property set /PROP/TYPE9 (SH_ORTH) or /PROP/TYPE10 (SH_COMP).

- The yield stress is defined by a

user function and the yield stress is compared to equivalent stress:

(1) - Angles for Lankford parameters are

defined with respect to orthotropic direction 1.

(2) The Lankford parameters ra is the ratio of plastic strain in plane and plastic strain in thickness direction .

(3) Where, α is the angle to the orthotropic direction 1.

This Lankford parameters ra could be determined from a simple tensile test at an angle α.

A higher value of R means better formability.

- If the last point of the first (static) function equals 0 in stress, default value of is set to the corresponding value of .

- Element deletion:

- Once (plastic strain) reaches , in one integration point, the element is deleted.

- If

reaches

, the stress is reduced using the following relation:

(4) - If (largest principal strain) reaches ( ), the stress in element is reduced to 0 (but the element is not deleted).

- Once (largest principal strain) reaches (maximum tensile failure strain), the element is deleted.

- The maximum number of curves that can be input is 10.

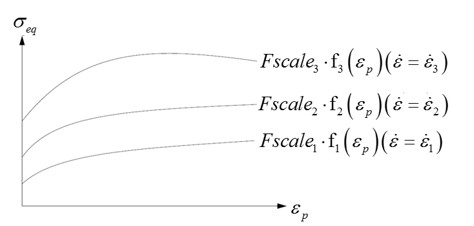

- If , the yield is interpolated between and .

- If , function is used.

- Above

, yield is extrapolated.

Figure 1. - Radial return is not available (only iterative plasticity).

- If the yield stresses have been obtained in the orthotropic direction 1, define Iyield0 =1; otherwise Iyield0 =0.

- The evolution of Young's

modulus:

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain

, which means the Young's modulus is scaled by the

function

:

(5) The initial value of the scale factor should be equal to 1 and it decreases.

- If fct_IDE = 0, the Young's modulus is calculated as:

(6) Where, and are respectively the initial and asymptotic value of Young's modulus, and is the accumulated equivalent plastic strain.

Note:If fct_IDE = 0 and CE = 0, Young's modulus E is kept constant.

- If fct_IDE > 0, the curve defines a scale factor for Young's modulus

evolution with equivalent plastic strain

, which means the Young's modulus is scaled by the

function

:

- The parameters Fsmooth and Fcut

allow you to enable strain-rate filtering. Three cases can be set:

- If Fsmooth = 0 + Fcut = 0.0, the strain-rate filtering is turned off.

- If Fsmooth = 1 + Fcut = 0.0, the strain-rate filtering uses a default cutoff frequency of 10 kHz.

- If Fcut ≠ 0, Fsmooth is automatically set to 1 and the strain-rate filtering uses the cutoff frequency provided by you.