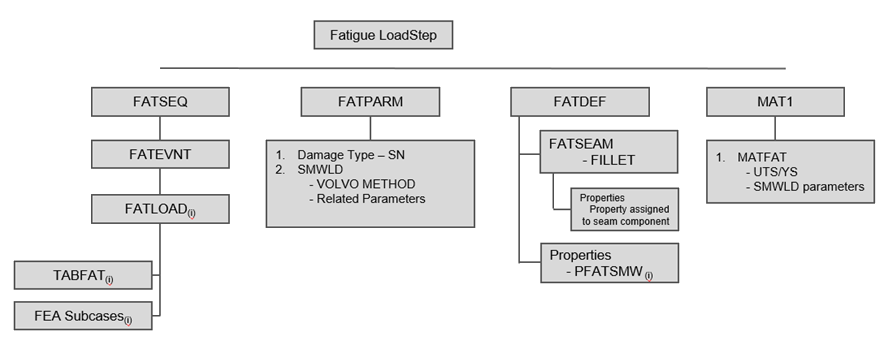

Seam Weld Fatigue using S-N Method

The method is a hot-spot stress approach applicable to thin metal sheets.

Hot-spot stress is calculated from grid point forces at the weld line. The method showed a good agreement with laboratory test results for sheet thickness between 1.0 mm and 3.0 mm. The method typically requires two SN curves. One is a bending SN curve which is dominated by bending stress, and the other is a membrane SN curve which dominated by membrane stress.

The following file found in the optistruct.zip file is needed to perform this tutorial. Refer to Access the Model Files.

SeamWeld_frame.fem

or

A copy of the model files used in this tutorial are available on <install_directory>/tutorials/hwsolvers/optistruct.

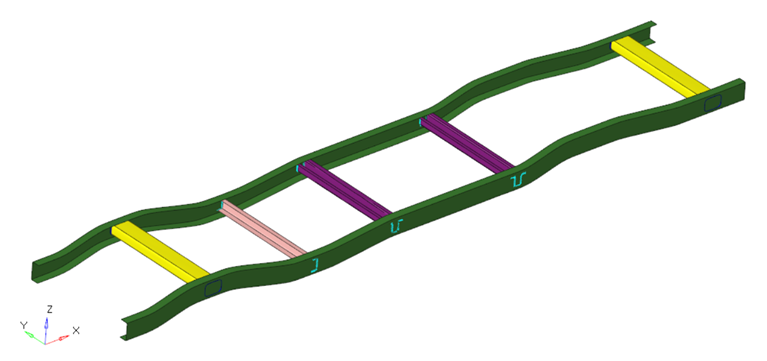

Figure 1. Automotive Frame

Launch HyperMesh and Set the OptiStruct User Profile

The model being used for this exercise is that of an automotive frame (Figure 1). The input file consists of 3 static loadsteps to which the frame is subjected to – Frontal torsion, Rear torsion and the Vertical bending.

Import the Model

Set Up the Model

Define TABFAT Load Collector

Define FATLOAD Load Collector

Create a fatload each for the loadcases present.

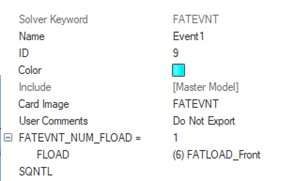

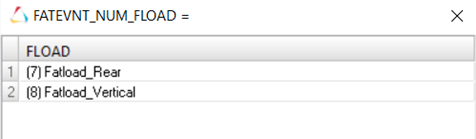

Define FATEVNT Load Collector

Create an event to assign the fatloads created.

Define FATSEQ Load Collector

Define Fatigue Parameters

Define Fatigue Material Properties

The material curve for the fatigue analysis can be defined on the MAT1 card.

Define PFATSMW Property

BRATIO helps understand if the Bending Moments or if the Membrane Forces dominates the maximum stresses based on which the interpolated SN curve is created.

Similarly, TREF and TREF_N help in accounting for thickness correction

- In the Model Browser, right-click and select .

- For Name, enter PFATSMW_7.

- For Card Image, select PFATSMW.

- Set BRATIO to 0.6.

- Set TREF to 1.1.

- Set TREF_N to 0.1.

- Click Close.

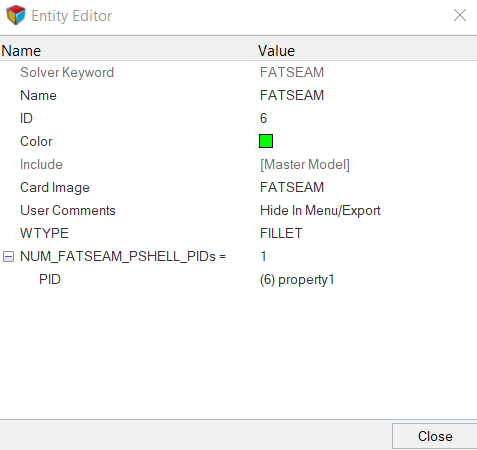

Define FATSEAM Load Collector

FATSEAM helps to select the seam weld type.

In this case it is the fillet weld.

Define FATDEF Load Collector

- In the Model Browser, right-click and select .

- For Name, enter FATDEF1.

- Set the Card Image to FATDEF.

- Activate FATSEAM in the PTYPE Entity Editor.

- For FATDEF_FATSEAM_NUMIDS, enter 1.

- Select FatSeam for FATSEAMID and PFATSMW_7 for PFATSMWID.

- Click Close.

Define the Fatigue Load Step

- In the Model Browser, right-click and select .

- For Name, enter Fatigue_3LCs_SeamWeld.

- Set the Analysis type to fatigue.

- For FATDEF, select fatdef.

- For FATPARM, select fatparam.

- For FATSEQ, select fatseq.

.

.

to open the

to open the