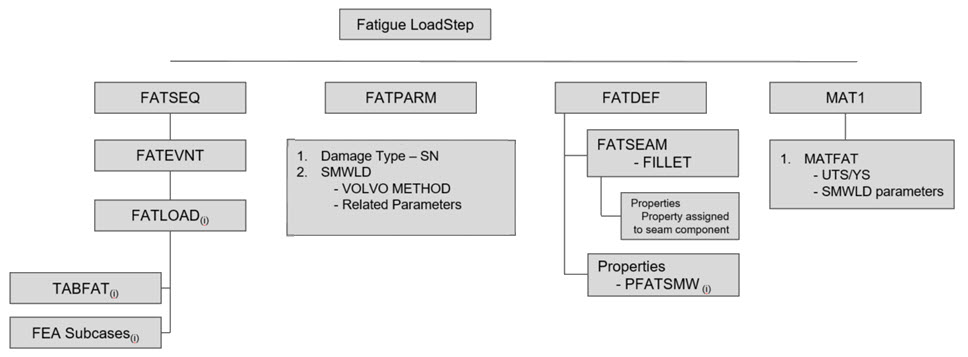

Spot Weld Fatigue (FPM) using S-N Method

Spot weld fatigue can only be applied to spot welds between two shells. The spot weld location is defined by three attributes, sheet 1, sheet 2, and the nugget. The sheets are defined by shell elements, and the nugget is defined by CWELD, CBAR, CBEAM, or CHEXA elements. The nugget can be directly connected to the shells or RBE2/RBE3 elements can be used to connect the nugget to the shells.

The following file found in the optistruct.zip file is needed to perform this tutorial. Refer to Access the Model Files.

SpotWeld_CbarNugget.fem

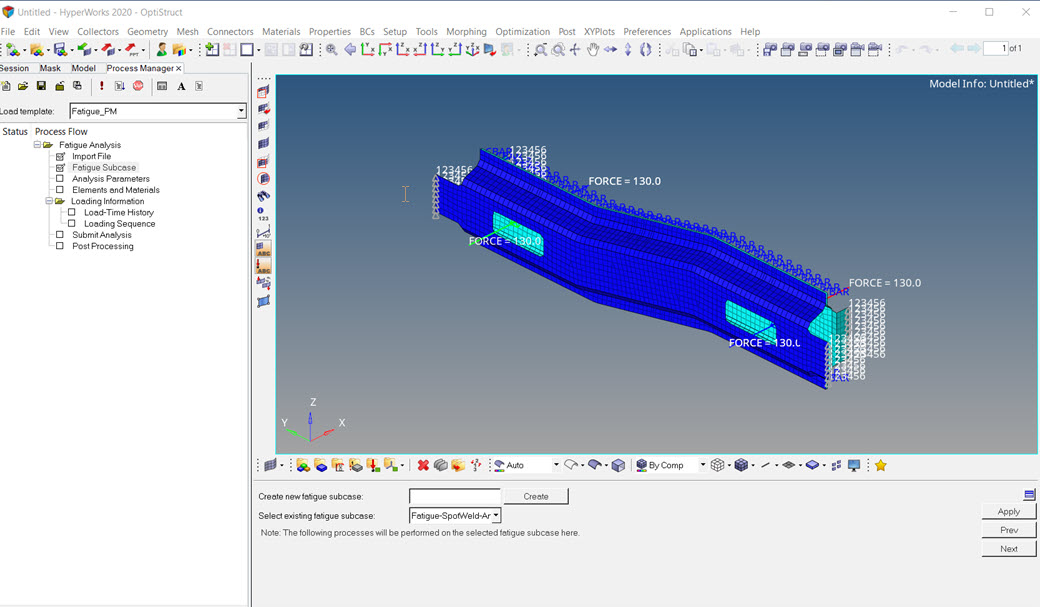

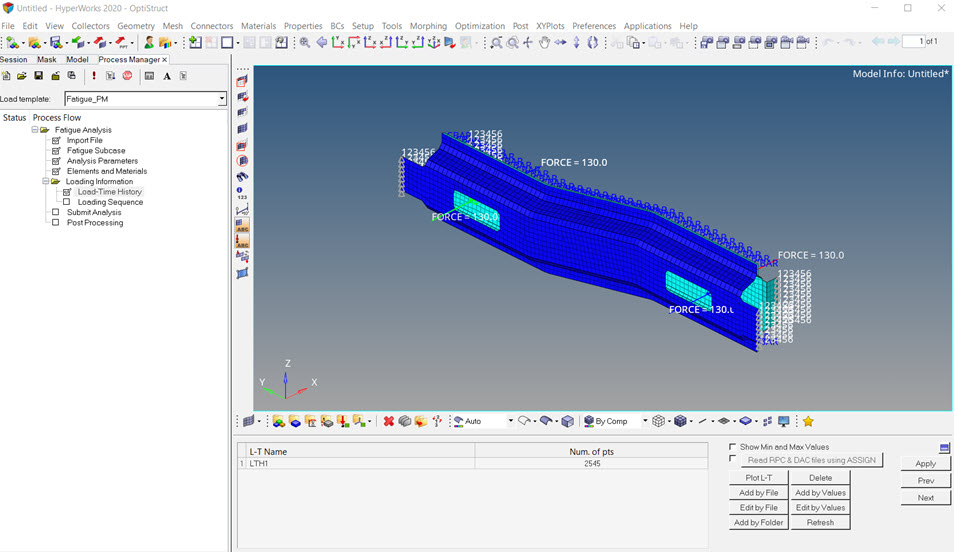

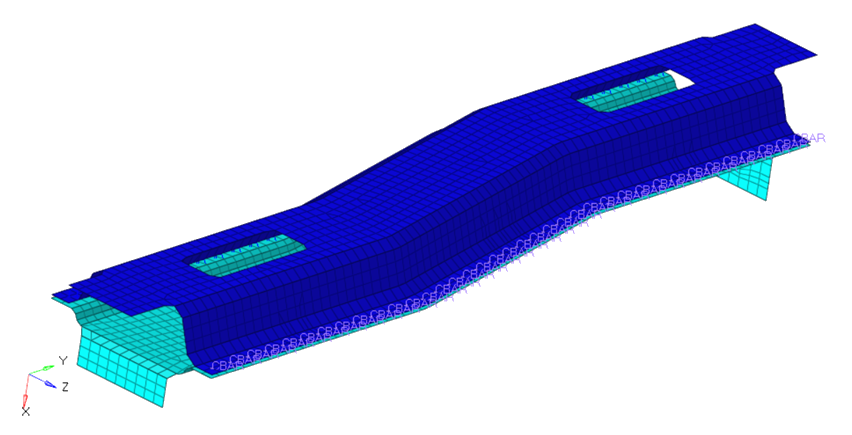

Figure 1. Spot Welds Modeled between Two Frame Sections

- Launch Fatigue Process Manager

- Import a model

- Create fatigue subcase

- Define fatigue analysis parameters

- Define fatigue elements and S-N properties

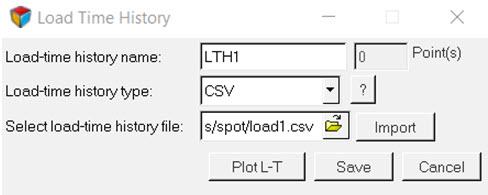

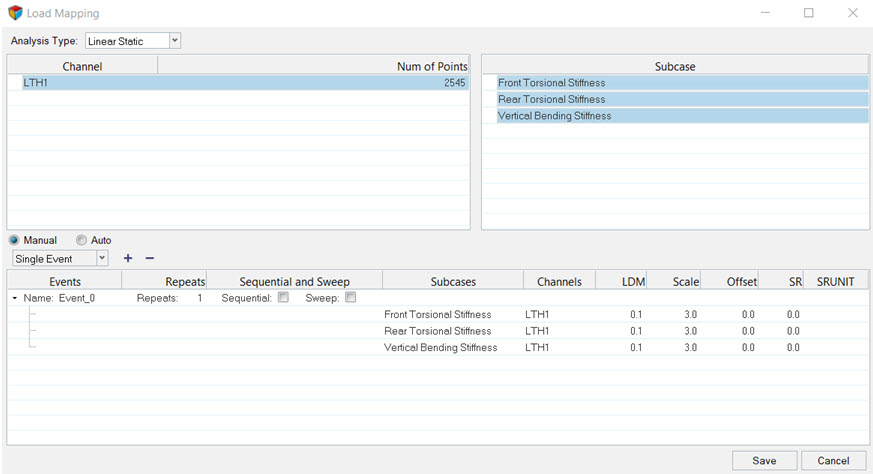

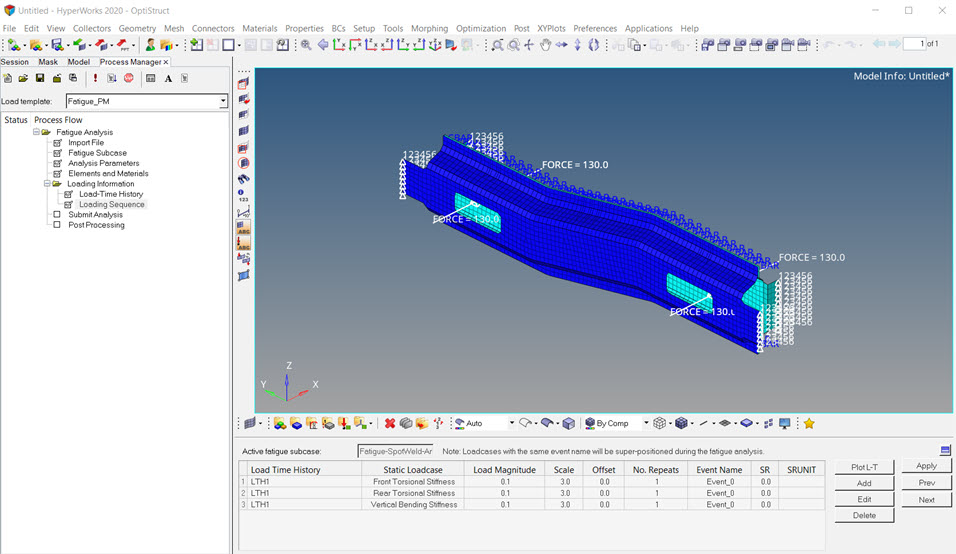

- Define load-time history and loading sequence

- Submit the job

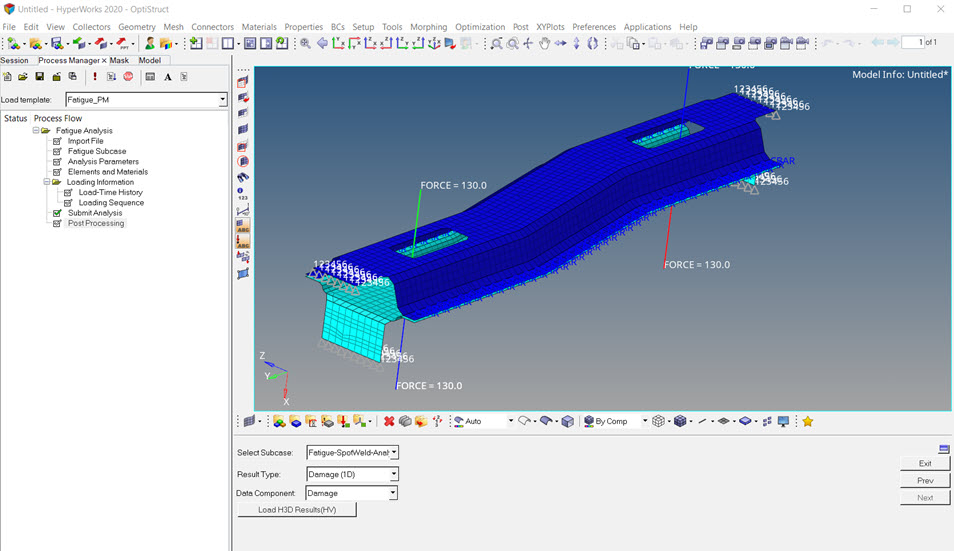

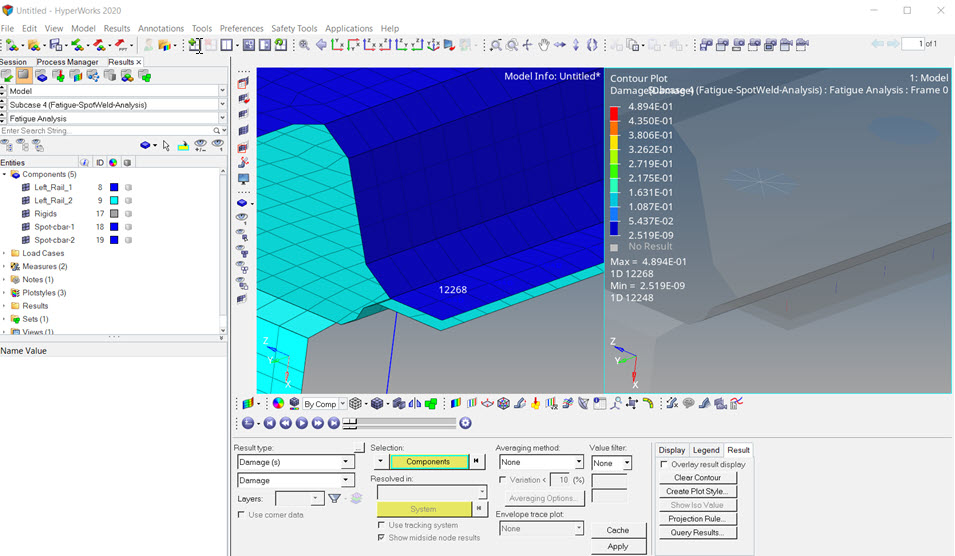

- View results summary and launch HyperView for post-processing

Launch HyperMesh and Set the OptiStruct User Profile

The model being used for this exercise is that of an automotive frame (Figure 1). The input file consists of 3 static loadsteps to which the frame is subjected to – Frontal torsion, Rear torsion and the Vertical bending.

Import the Model

Set Up the Model

Create a Fatigue Subcase

Define Fatigue Parameters

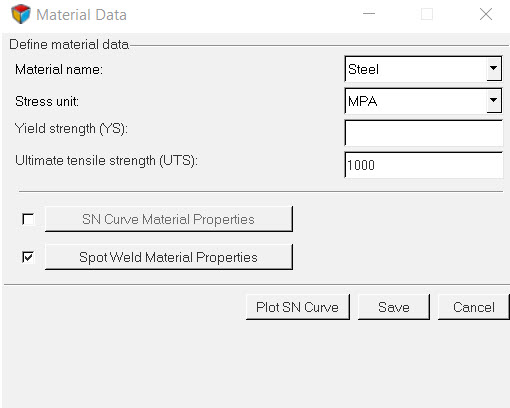

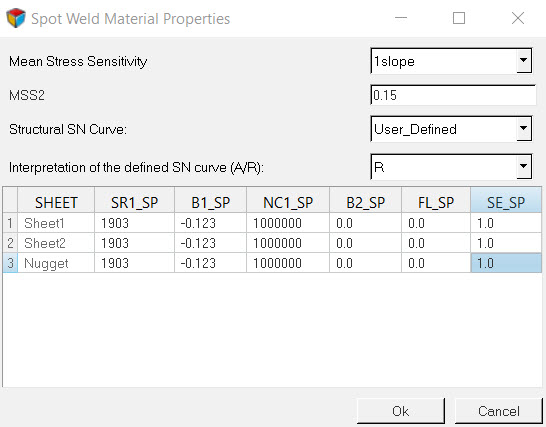

Add Fatigue Elements and Materials

Make sure the task Elements and Materials is selected in the Fatigue Analysis tree.

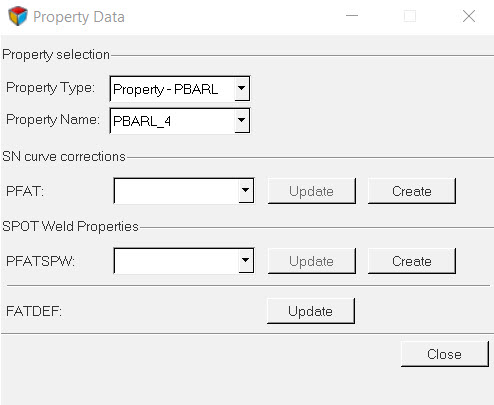

Define PFATSPW Property

- In the Model Browser, right-click and select .

- For Name, enter PFATSPW.

- For Card Image, select PFATSPW.

- Set SPTFAIL to All.

- Set ALPHA to 3.5.

- Set TREF to 1.0.

- Set TREF_N to 0.2.

- Set SF to 1.0.

- Click Close.

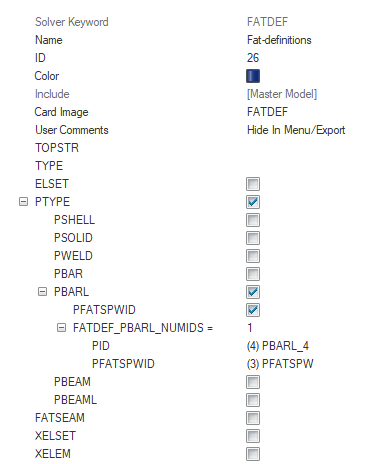

Define FATDEF Load Collector

Apply Load-Time History

Load Sequences

Submit the Job

Make sure the task Submit Analysis is selected in the Fatigue Analysis tree.

.

.