/MONVOL/AIRBAG (Obsolete)

Block Format Keyword Describes the airbag monitored volume type.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MONVOL/AIRBAG/monvol_ID/unit_ID | |||||||||

| monvol_title | |||||||||

| surf_IDex | |||||||||

| Ascalet | AscaleP | AscaleS | AscaleA | AscaleD | |||||

| Pext | T0 | equi | Ittf | ||||||

| cpai | cpbi | cpci | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Njet |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| cpa | cpb | cpc | |||||||

| fct_IDmas | Iflow | Fscalemas | fct_IDT | FscaleT | sens_ID | ||||

| Ijet | node_ID1 | node_ID2 | node_ID3 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fct_IDPt | fct_IDP | fct_IDP | Fscalept | Fscalep | Fscalep | ||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Nvent |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| surf_IDv | Avent | Bvent | Tstop | ||||||

| Tvent | fct_IDV | FscaleV | IdtPdef | ||||||

| fct_IDt | fct_IDP | fct_IDA | Fscalet | FscaleP | FscaleA | ||||

| fct_IDt' | fct_IDP' | fct_IDA' | Fscalet' | FscaleP' | FscaleA' | ||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| monvol_ID | Monitored volume

identifier (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier (Integer, maximum 10 digits) |

|

| monvol_title | Monitored volume

title (Character, maximum 100 characters) |

|

| surf_IDex | External surface

identifier 1 (Integer) |

|

| Ascalet | Abscissa scale factor for

time based functions Default = 1.0 (Real) |

|

| AscaleP | Abscissa scale factor for

pressure based functions Default = 1.0 (Real) |

|

| AscaleS | Abscissa scale factor for

area based functions Default = 1.0 (Real) |

|

| AscaleA | Abscissa scale factor for

angle based functions Default = 1.0 (Real) |

|

| AscaleD | Abscissa scale factor for

distance based functions Default = 1.0 (Real) |

|

| mat_ID | Initial gas material

identifier (/MAT/GAS) (Real) |

|

| Volumetric

viscosity Default = 0.01 (Real) |

||

| Pext | External

pressure (Real) |

|

| T0 | Initial

temperature. Default = 295 (Real) |

|

| Iequi | Initial thermodynamic

equilibrium flag.

(Integer) |

|

| Ittf | Venting time shift flag.

Active only when injection sensor is specified.

|

|

| Ratio of specific heats at

initial temperature

(Real) |

||

| cpai | cpa

coefficient in the relation

cpi(T) (Real) |

|

| cpbi | cpb

coefficient in the relation

cpi(T) (Real) |

|

| cpci | cpc

coefficient in the relation

cpi(T) (Real) |

|

| Njet | Number of

injectors (Integer) |

|

| Ratio of specific heats

(Real) |

||

| cpa | cpa

coefficient in the relation cp(T) (Real) |

|

| cpb | cpa

coefficient in the relation cp(T) (Real) |

|

| cpc | cpa

coefficient in the relation cp(T) (Real) |

|

| surf_IDv | Vent holes membrane

surface identifier (Integer) |

|

| Avent | If

surf_IDv ≠

0: scale factor on surface Default = 1.0 If surf_IDv = 0: surface of vent holes Default = 0.0 (Real) |

, if surf_IDV = 0 |

| Bvent | If

surf_IDv ≠

0: scale factor on impacted surface Default = 1.0 If surf_IDv = 0: Bvent is reset to 0. Default = 0.0 (Real) |

, if surf_IDV = 0 |

| Tstop | Stop time for

venting Default = 1E+30 (Real) |

|

| Tvent | Start time for

venting Default = 0.0 (Real) |

|

| Pressure difference to

open vent hole membrane (

=

Pdef - Pext) (Real) |

||

| Minimum duration pressure

exceeds Pdef to

open vent hole membrane (Real) |

||

| fct_IDV | Outflow velocity function

identifier (Integer) |

|

| FscaleV | Scale factor on

fct_IDV Default = 1.0 (Real) |

|

| IdtPdef | Time delay flag when

is reached:

|

|

| fct_IDt | Porosity versus time

function identifier (Integer) |

|

| fct_IDP | Porosity versus pressure

function identifier (Integer) |

|

| fct_IDA | Porosity versus area

function identifier (Integer) |

|

| Fscalet | Scale factor for

fct_IDt Default = 1.0 (Real) |

|

| FscaleP | Scale factor for

fct_IDP Default = 1.0 (Real) |

|

| FscaleA | Scale factor for

fct_IDA Default = 1.0 (Real) |

|

| fct_IDmas | Mass of injected gas

versus time function identifier (Integer) |

|

| Iflow | Mass versus time function

input type flag

(Integer) |

|

| Fscalemas | Mass function scale

factor Default = 1.0 (Real) |

or |

| fct_IDT | Temperature of injected

gas versus time function identifier (Integer) |

|

| FscaleT | Temperature function scale

factor Default = 1.0 (Real) |

|

| sens_ID | Sensor

identifier. (Integer) |

|

| Ijet | Jetting flag.

(Integer) |

|

| node_ID1, node_ID2, node_ID3 | Node identifiers

N1,

N2, and

N3 for jet shape

definition. (Integer) |

|

| fct_IDPt | If

Ijet =

1: identifier of the function number defining

. (Integer) |

|

| fct_IDP | If

Ijet =

1: identifier of the function number defining

) (Integer) |

|

| fct_IDP | If

Ijet =

1: identifier of the function number defining

(Integer) |

|

| FscalePt | If

Ijet =

1: scale factor for

fct_IDPt Default = 1.0 (Real) |

|

| FscaleP | If

Ijet =

1: scale factor for

fct_IDP

Default = 1.0 (Real) |

|

| FscaleP | If

Ijet =

1: scale factor for

fct_IDP

Default = 1.0 (Real) |

|

| Nvent | Number of vent

holes. (Integer) |

|

| fct_IDt' | Porosity versus time when

contact function identifier. (Integer) |

|

| fct_IDP' | Porosity versus pressure

when contact function identifier. (Integer) |

|

| fct_IDA' | Porosity versus impacted

surface function identifier. (Integer) |

|

| Fscalet' | Scale factor for

fct_IDt' Default = 1.0 (Real) |

|

| FscaleP' | Scale factor for

fct_IDP' Default = 1.0 (Real) |

|

| FscaleA' | Scale factor for

fct_IDA' Default = 1.0 (Real) |

Comments

- surf_IDex must be defined using segments associated with 4-nodes or 3-nodes shell elements (possibly void elements).

- The volume must be closed and the normals must be oriented outwards.

- Abscissa scale factors

are used to transform abscissa units in airbag functions, for

example:

(1) Where, t is the time.

For example, if your input data is in [ms], but you need a data in [s], you could set Ascale to 0.001.(2) Where, p is the pressure.

- Initial pressure is set to Pext.

- Initial thermodynamic

equilibrium is written at time zero

(Iequi =0)

or at beginning of jetting (Iequi

=1), based on the following equation with respect to the volume

at time zero, or the volume at beginning of jetting:

where, M0 is the mass of gas initially filling the airbag, Mi is the molar mass of the gas initially filling the airbag, and R is the gas constant depending on the units system.

(3) - Ratio of specific heats

at constant pressure per mass unit

cpi of the gas initially

filling the airbag is quadratic versus temperature:

(4) - Gas constant at initial

temperature

i must be related to specific

heat per mass unit at initial temperature and molar mass of the gas initially

filling the airbag with respect to the following relation:

(5) Where, Mi is the molar mass of the gas initially filling the airbag, and R is the gas constant depending on the units system.(6) - The characteristics of the gas initially filling the airbag must be defined (no default) and must be equal for each communicating airbag.

- If i = 0, the characteristics of the gas initially filling the airbag are set to the characteristics of the gas provided by the first injector.

- Ratio of specific

heats at constant pressure per mass unit

cpi of the gas is quadratic

with regard to the temperature:

(7) - Gas constant at

initial temperature

must be related to specific heat per mass unit at initial

temperature and molar mass of the with respect to the following

relation:

(8) Where,- M

- Molar mass of the gas

- R

- Gas constant depending on the units system

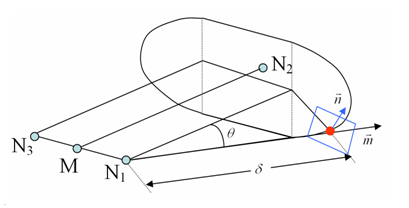

(9) - If jetting is used, an

additional

Pjet pressure is applied to

each element of the airbag:

(10) - With

being the normalized vector between the

projection of the center of the element upon segment (node_ID1 and node_ID3) and the center of

the element;

the angle between vectors

MN2 and

(in degrees),

is the distance between the center of the element and

its projection upon segment (node_ID1 and node_ID3).The projection of a point upon segment (node_ID1 and node_ID3) is defined as the projection of the point in direction MN2 upon the line (node_ID1 and node_ID3) if it lies inside the segment (node_ID1 and node_ID3). If this is not the case, the projection of the point upon segment (node_ID1 and node_ID3) is defined as the closest node node_ID1 or node_ID3.

Figure 1. Dihedral Shape of the Jetwith M between N1 and N3

- If node_ID3 = 0, node_ID3 is set to node_ID1 and the dihedral shape is reduced to a conical shape.

- If

fct_IDV = 0:

isenthalpic outflow is assumed, else Chemkin model is used and outflow velocity

is:

(11) - Isenthalpic model

Venting or the expulsion of gas from the volume, is assumed to be isenthalpic.

The flow is also assumed to be unshocked, coming from a large reservoir and through a small orifice with effective surface area, A.

Conservation of enthalpy leads to velocity, u, at the vent hole. The Bernouilli equation is then written as:

(monitored volume) (vent hole)

Applying the adiabatic conditions:

(monitored volume) (vent hole)

Where, P is the pressure of gas into the airbag and is the density of gas into the airbag.

Therefore, the exit velocity is given by:(12) For supersonic flows the outlet velocity is determined as described in 10.4.4.1 of the Theory Manual.

The mass out flow rate is given by:(13) The energy flow rate is given by:(14) Where, V is the airbag volume and E is the internal energy of gas into the airbag.

- Chemkin model

(15) Where, is the density of the gas within the airbag.

- Isenthalpic model

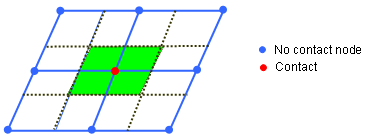

- Vent holes surface is

computed as follows:

(16) (17) with impacted surface:(18) and non-impacted surface:(19) Where for each element e of the vent holes surf_IDv, nc(e) means the number of impacted nodes among the n(e) nodes defining the element.

Figure 2. From Nodes Contact to Impacted/Non-impacted Surface - Functions fct_IDt' and fct_IDP' are assumed to be equal to 1, if they are not specified (null identifier).

- Function fct_IDA' is assumed as the fct_IDA'(A) = A, if it is not specified.

- In order to use porosity during contact, flag IBAG must be set to 1 in the interfaces concerned (Line 3 of interface Type 5 and Type 7). If not, the nodes impacted into the interface are not considered as impacted nodes in the previous formula for Aimpacted and Anon_impacted.

- When defining venting,

there are some limitations concerning the definition of airbag surface and surface venting:

- The airbag external surface should be built only from shells and 3-nodes shell elements.

- The airbag external surface can not be defined with option /SURF/SEG (or with option /SURF/SURF if a sub-surface is defined with option /SURF/SEG).

- Same restriction applies to vent hole surface.

- Shells and 3-nodes shell elements included in vent hole surface have to also be included in external surface.

- Vent hole membrane is deflated if T > Tvent or if the pressure exceeds Pdef during more than .