JointLoad Method

The Rivet config is shipped with an internal method called JointLoad. This method determines the load transfer through bolted connections and the associated bypass and bearing loads in the adjoining plates. The JointLoad method extracts the internal loading in the plates and bolts of concern. The extracted data can either be:

- An ASCII text file (*.csv) written to disk at run

time.

- Files are subsequently parsed to feed an external static strength analysis.

- Written inside tables in the HyperWorks session

and saved in a binary file.

- Tables can later be exported to an ASCII text file.

- Tables can also be used by subsequent chained methods running after JointLoad to assess margin of safety.

Fastener Modelization

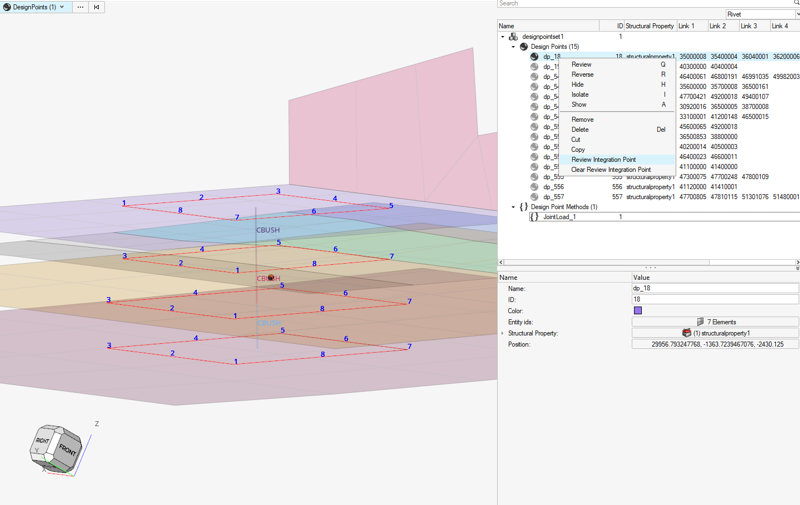

This method is tailored to run on designpoints of configuration Rivet. While generating a Rivet, the expectation is to have a collection of Pierced_shell-1D- Pierced_shell... that represent the fastener (Figure 1).

- Rutman modelization is not supported yet for force extraction.

- So called “Tension bolts” where each internal body between plates sustains shear only plus 1 element linking the top/bottom plates with tension stiffeness only are not supported in Fastener detection.

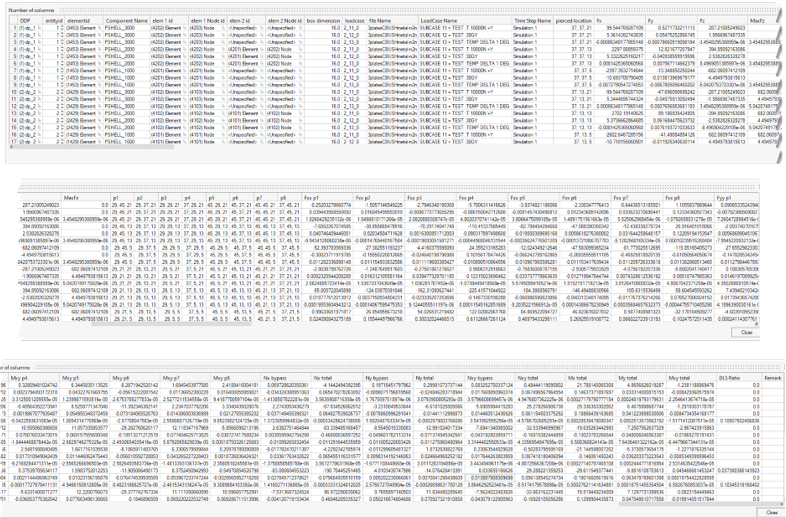

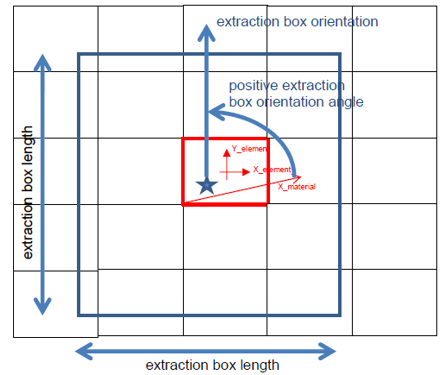

Figure 1. Review extraction areas per plate

Force Extraction

Fastener Forces

There are direct extractions of all 1D element forces Fx, Fy, Fz and bearing loads at the node interface between two 1D elements in case of multiple lap joints.

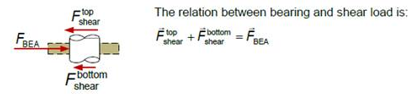

It should be noticed at this stage the difference between the fastener bearing load and the fastener shear load (Figure 2). For external plates, the shear and bearing load are equivalent because there is only one interface. For middle plates, the maximum absolute interface load is taken as the fastener shear load.

Figure 2. Bearing force

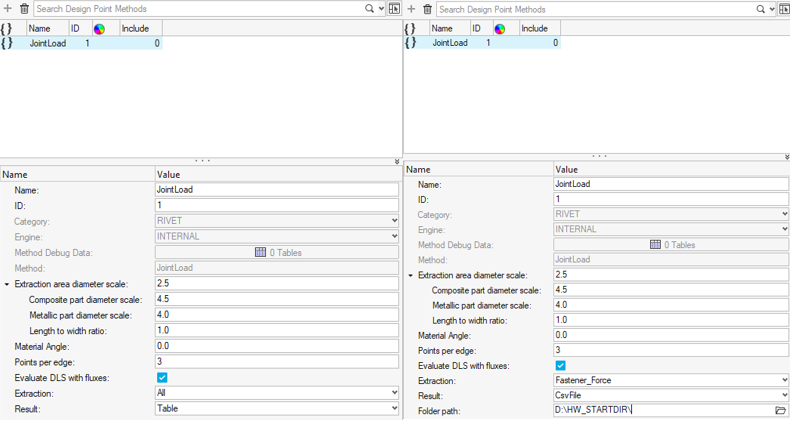

The pierced shell material system is used as a reference system to project Fx, Fy. The shell material system X axis is used as a reference along with the 1D element (X) axis to define the normal side (Z), and hence the local (X,Y,Z) is defined by two cross product. Shear force components of 1D elements are projected in that system. The JointLoad method provides an input Material Angle (Figure 3) which allows you to rotate the system by a given angle around the shell normal.

It is worth noting that the material system used by the method is coming from the model in the current session, no matter which system was set in the Analysis run. This could be used as a post-processing workaround to extract forces in a different system.

Whenever there is a lap joint, the contribution of 1D elements from both sides are properly summed.

Regarding the extraction of tension force, the pull-through force is rearranged by considering 1D direct element axial force (Fx) without projection. Output is reversed only if it is the output of 1D’s second node; otherwise the axial force is used directly

The method outputs a value called MaxFz (max tension in fastener). This is the max value among calculated Fz, where 0 is returned if the bolt is in compression.

Figure 3. Extraction options

Shell Forces

- Extraction area diameter scale (def 2.5)

- Composite part diameter scale (def 4.5)

- Metallic part diameter scale (def 4.0)

- Length to width ratio (def 1.0)

Each fastener has a structural property assigned from which you can define a diameter. To calculate the box length from the fastener diameter and method level scale factors, the below formula is used:

Box length=0.4*AreaScale*FastenerDiameter*Material_Diameterscale

Figure 4.

The length to width ratio applies on nominal Box length from the above formula and allows for a rectangular shape if the ratio is not 1.0.

The extraction box is aligned with a pierced shell's material system as described above; hence, the parameter Material Angle allows you to rotate the box from the material X axis. The parameter Point per edges samples points per edge.

A field of shell forces/moments Nxx, Nyy, Nxy, Mx, My, Mxy is performed after averaging values from elements on nodes (considering corner data if available in the result file). A field query is performed in the material coordinate system on box edges on sampled points per edge. The number of integration points (points per edge) default to 3 but can be changed.

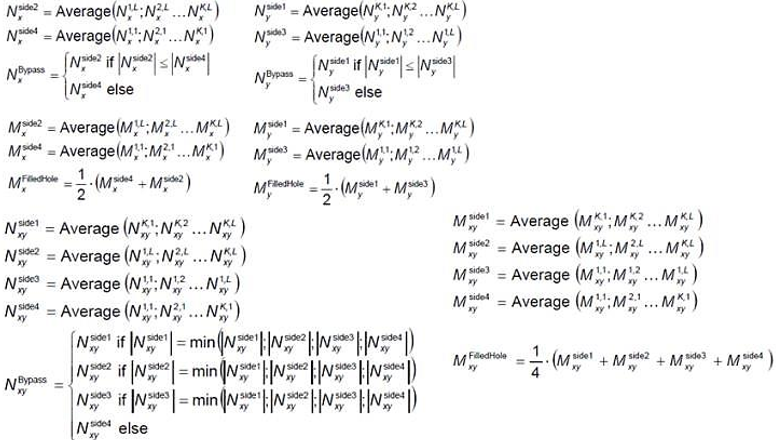

Force fluxes (resp. Moment fluxes) are evaluated per edge as an average of values on edge points (interpolated from the field at each point location). ByPass and Total fluxes are evaluated using the following equations:

Figure 5.

Extraction is done per pierced shell of a Rivet designpoint.

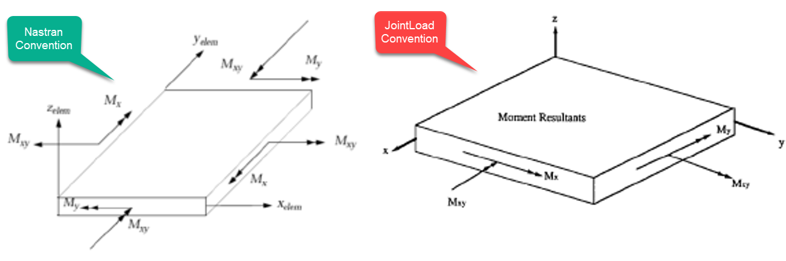

The tool also supports moment sign convention and correction in case of offsets (Figure 6 & Figure 7).

It extracts plate moments at the midplane. Nastran/OptiStruct element force results are given at the element reference plane and the reference plane coincides with the midplane even if element offsets (ZOFFS) are used. However, PCOMP Z0 != -t/2, this is no longer the case and moments must be corrected from the reference plane back to the midplane (Figure 7). This correction is done by the tool prior to producing the output. To consider moment correction if extraction is not performed at the middle surface, the following method is followed:

Figure 6. Moment sign convention

Figure 7. Moment correction

Output Options

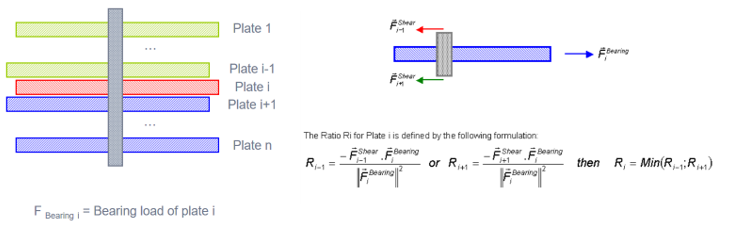

DLS Ratio

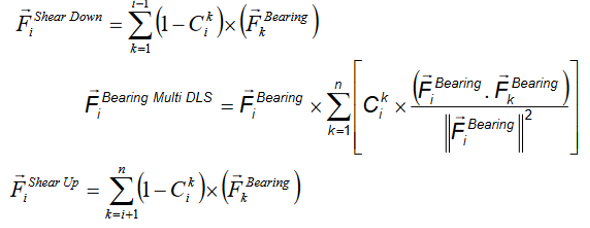

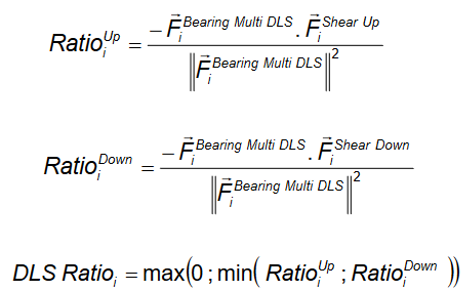

The method has a flag to evaluate DLS ratio (“true” by default) as seen in Figure 3. The DLS ratio is evaluated by the following procedure over each plate in the assembly:

Figure 8. DLS ratio

For a given plate, a ratio of the contribution of the Shear force over Bearing force from top/bottom elements is evaluated and the lowest is kept (Figure 8).

- Define Contribution for each plate Cik for plate

i

- Definition of Fbearing and Fshear for plate i

- Definition of DLS ratio for given plate i

Output Data and Format

Parameter Extraction (Figure 3) drives the output data written.

- Fastener Force

- Output per plate (elementid) the fastener forces and max tension (per loadcase).

- Forces and Fluxes

- Output per plate (elementid) the fastener forces along with Bypass fluxes and DLS ratio. Running in this mode gives all necessary results while reducing memory footprint compared to All.

- All

- Output all debug information along with previous results. It includes the point coordinates where extractions happen as well as raw data extracted (Nxx, Nyy, ...) at these locations. It also provides all details of the connection (ID of 1D elements linked to a plate) and box dimension. This results in 85 columns being created.

Another parameter – Result – drives how results are saved.

- Table (default)

- Creates a table entity in the HyperWorks

session, saved with the binary file.

- This is a mandatory option if a subsequent chained method aims to run after JointLoad.

- Csv File

- The run directly dumps result into a csv file on disk.

- It shows a folder location which defaults to the HyperWorks working directory.

- The file name is the same as the table name per RUN.

- The overwrite option has no impact here. The file name is always incremented if it already exists in the export directory.

- The generated csv file is comma-separated.

Prerequisites

JointLoad supports Nastran result formats as well as nanoFluidX[c] native *.h3d as result files.

- 1D element Forces

- 2D element Forces & Moments