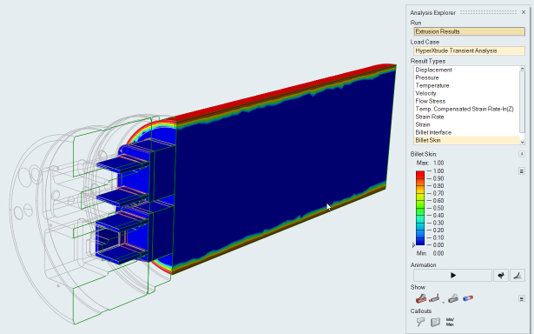

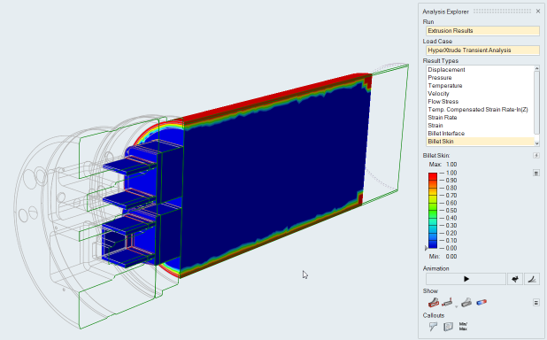

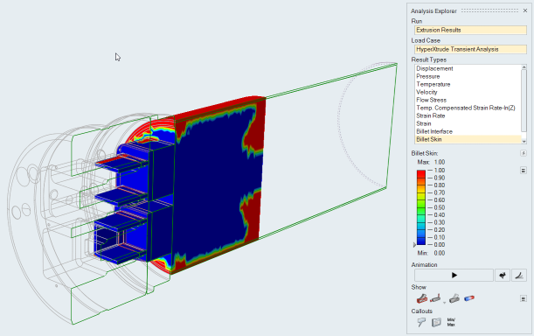

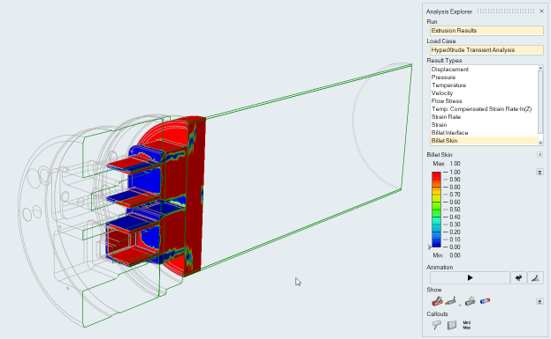

Tutorial: Billet Skin and Backend Defects

Use billet skin tracking analysis to determine when the billet skin enters the extrusion product and prevent impurities and defects.

During the extrusion process, it is important to prevent the impurities in the billet skin from entering the product. Billet skin tracking analysis can used to determine when the billet skin enters the extrusion product.

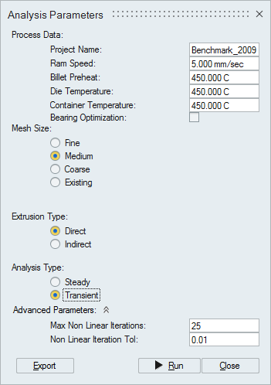

In Inspire Extrude, skin tracking analysis can be set up as a transient moving boundary analysis where the the movement of the dummy block and billet are simulated.

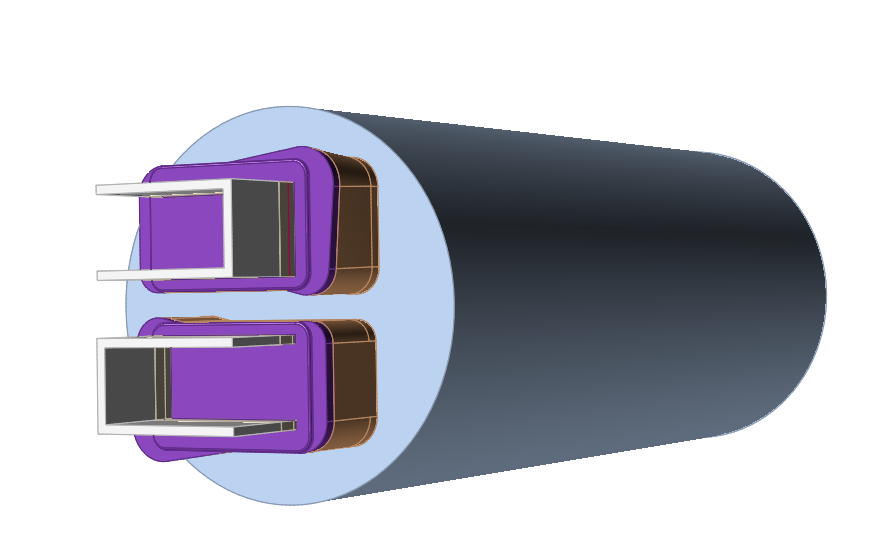

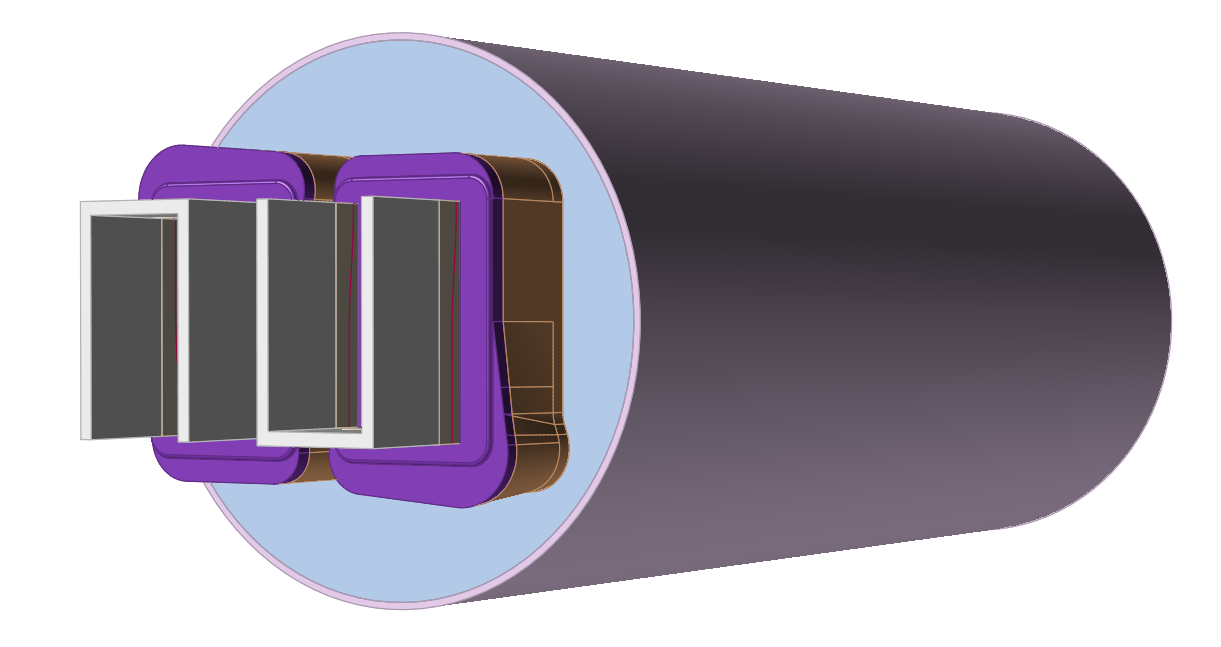

Load Model

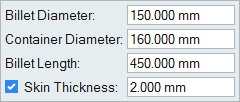

Create the Billet

We will specify the geometry to create the billet.

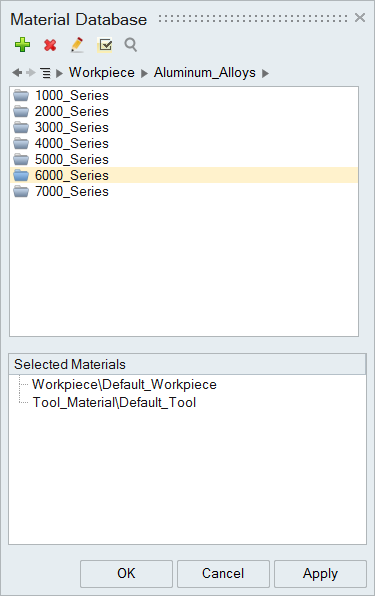

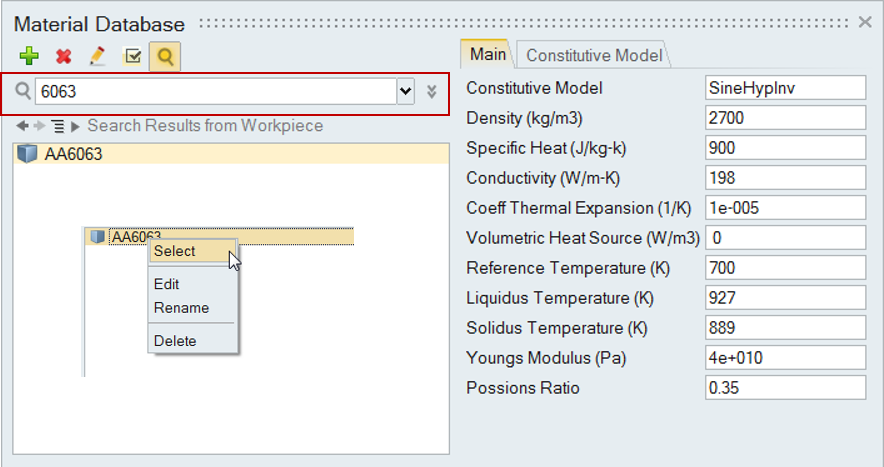

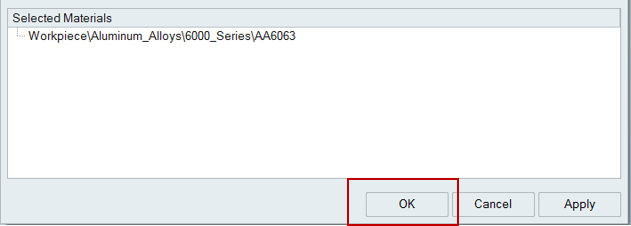

Select the Material

Specify Process Parameters and Simulate

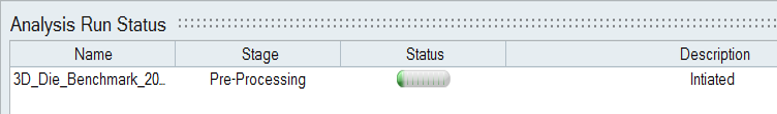

| Status after submitting the job |

|

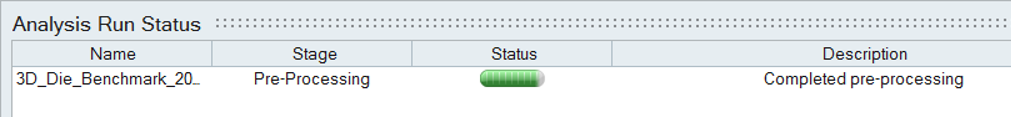

| Status after meshing is completed |

|

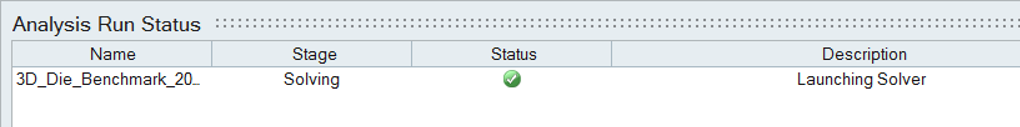

| Status when job is running in the solver |

|

Review the OUT File

The goal of post-processing is to understand the performance of the die. This is accomplished by studying the material flow and heat transfer in the model in HV. Before doing the detailed post-processing in HV, inspect the OUT file to get a quick overview of the results.

- Open the *.out file in a text editor.

- Inspect all data, applying the steps as outlined in the post-processing section.

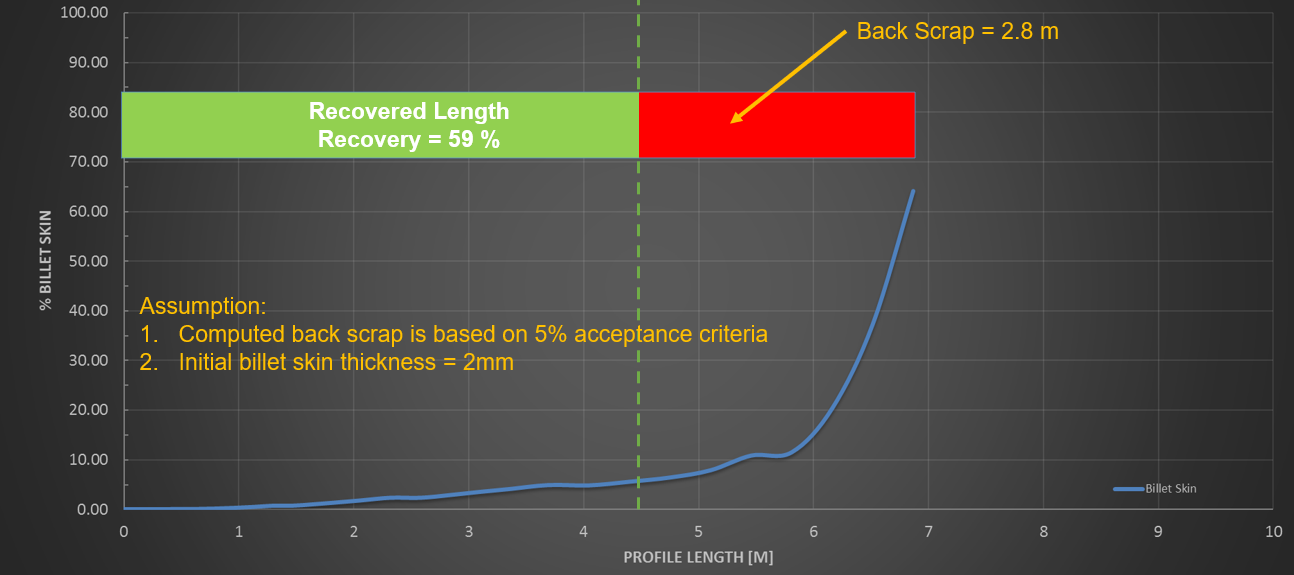

Analyze the Profile3D_volume.txt File

View Simulation Results