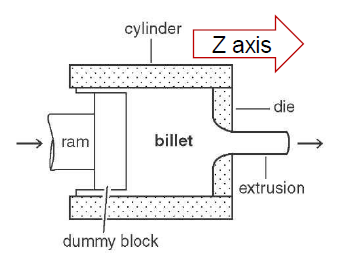

Tutorial: Hollow Profile Extrusion

Set up and complete a hollow profile extrusion analysis and post-process the data.

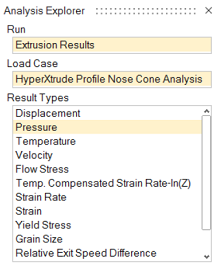

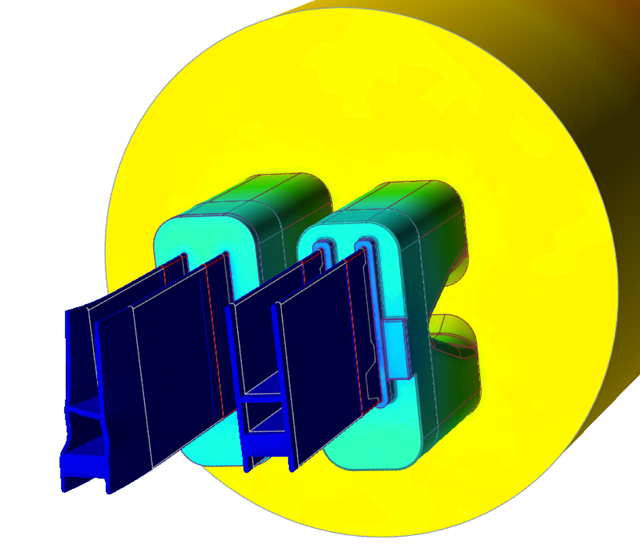

Model contains madrel and die cap. Two hollow profiles are being extruded through this die assembly. Data files are available in the tutorial_models folder in the installation directory in Program Files\Altair\2022\InspireExtrudeMetal2022.2\tutorial_models\extrudemetal\tutorial-2\.

Import and Orient Die Solids

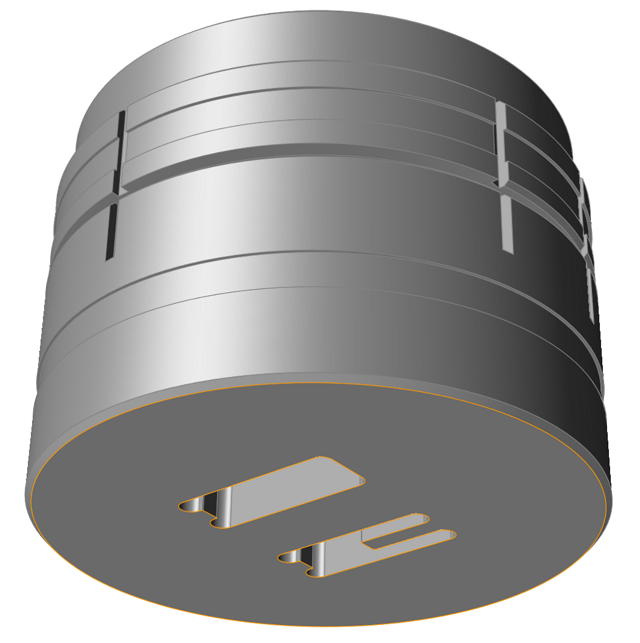

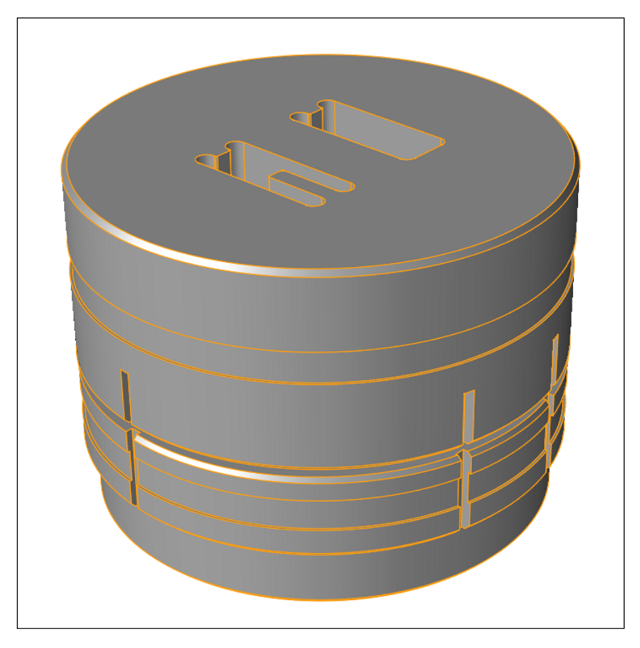

Extract Flow Volume

-

Click the Flow Volume icon to extract flow volume inside

of the die cavity.

-

Click and hold left mouse button while you drag a box around all the die solids

as shown.

-

Release left mouse button to extract flow volume automatically.

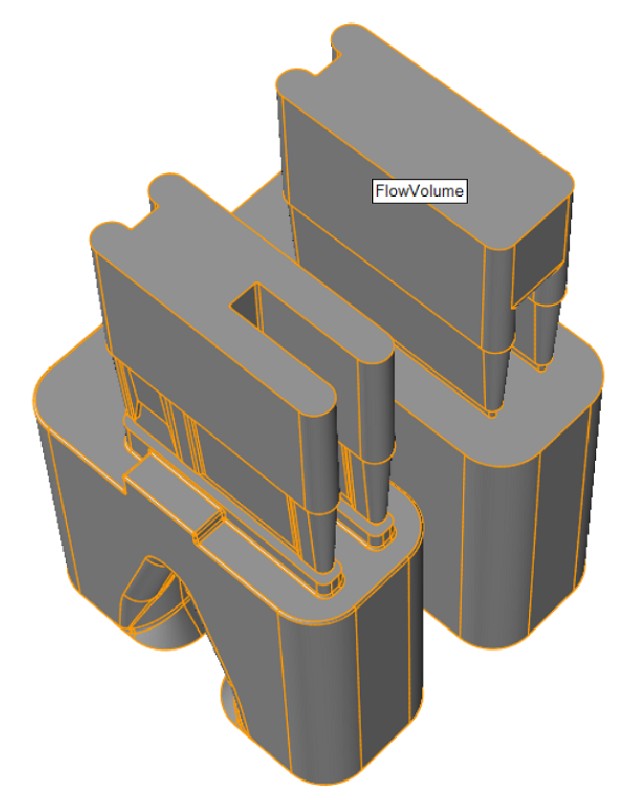

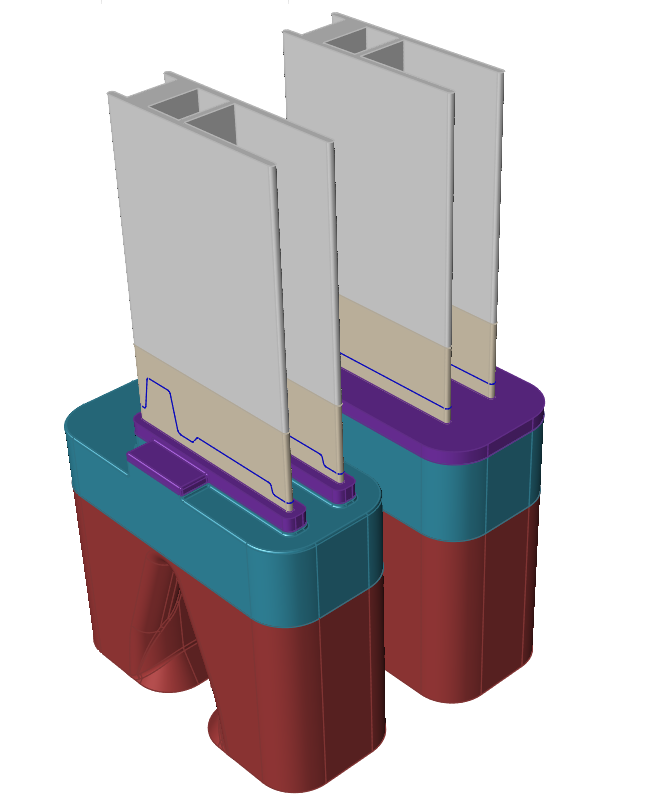

Combine Flow Volume

-

Hold CTRL and click on each flow solid as shown.

-

Right-click on either selected solid and click .

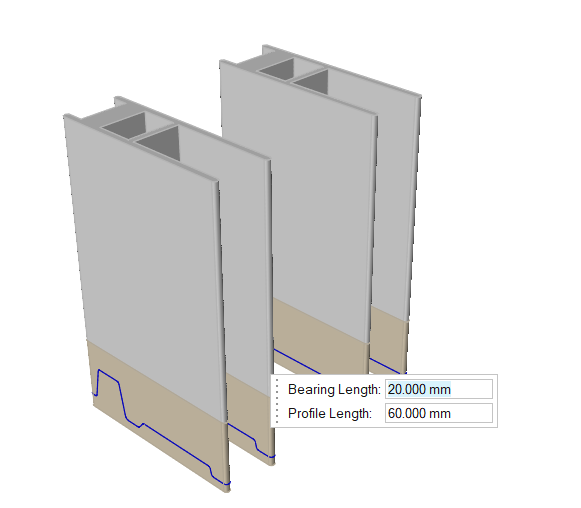

Extract Bearing Region

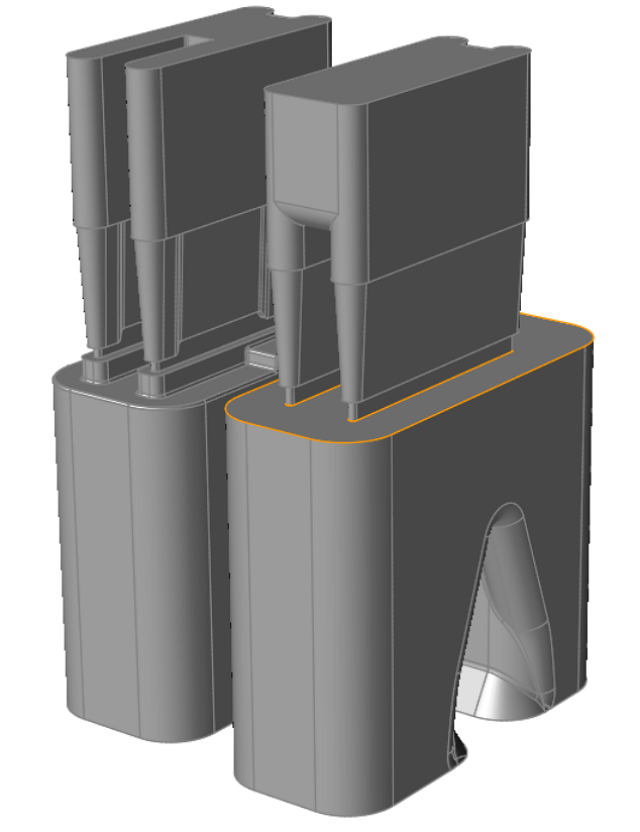

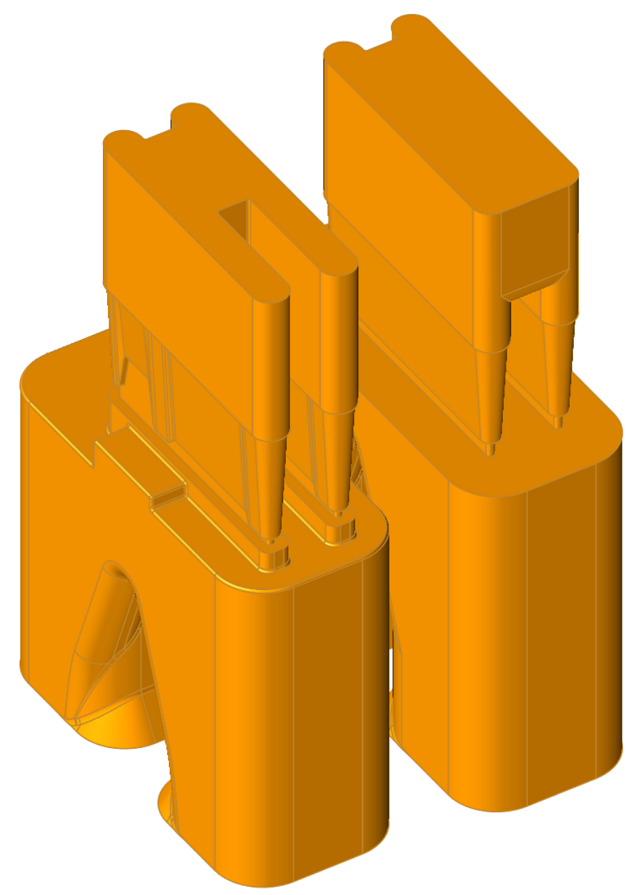

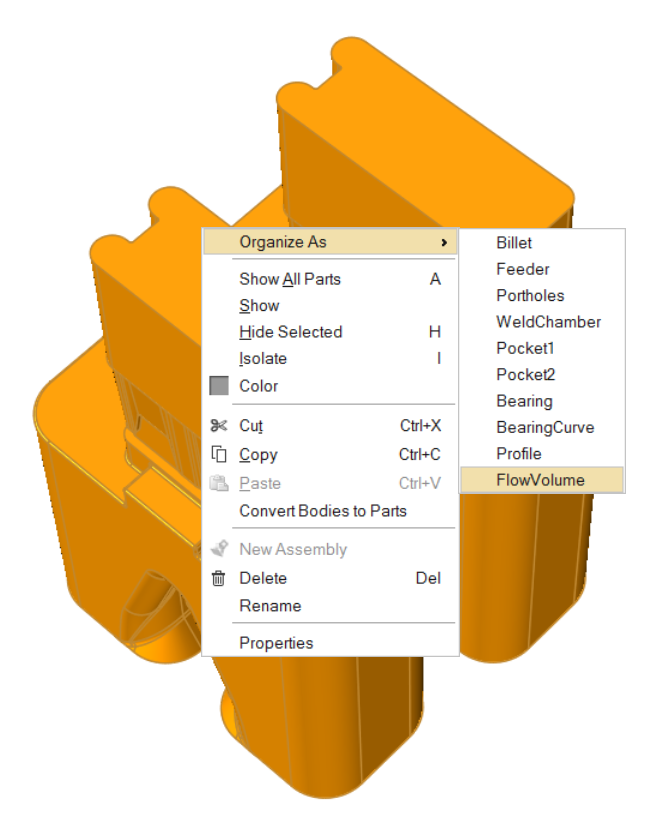

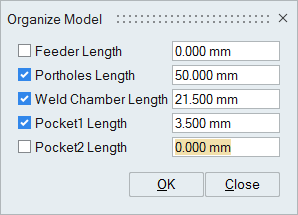

Organize Flow Volume

-

Click the Organize Volumes based on Length Icon.

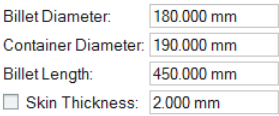

-

A micro dialogue will pop up, where you must enter the following

measurements:

- Press OK to close the window.

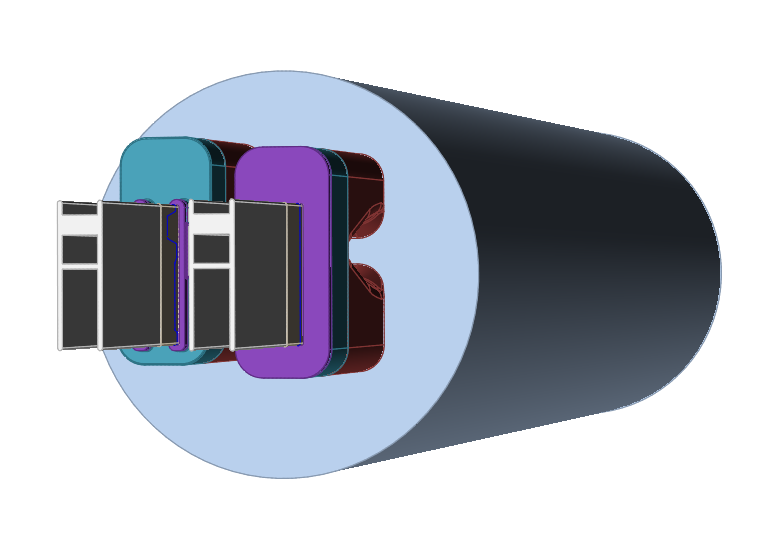

Create the Billet

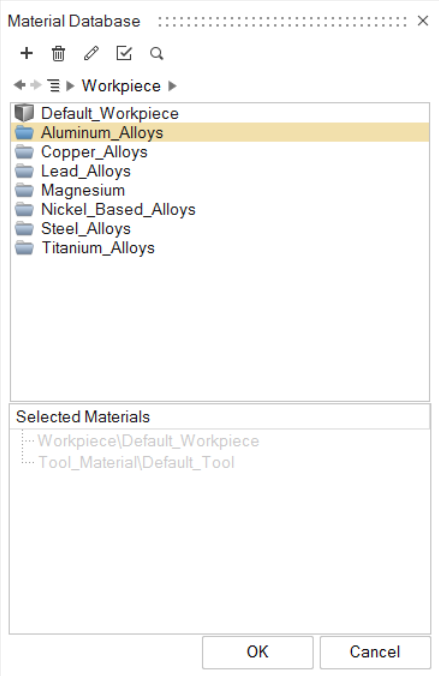

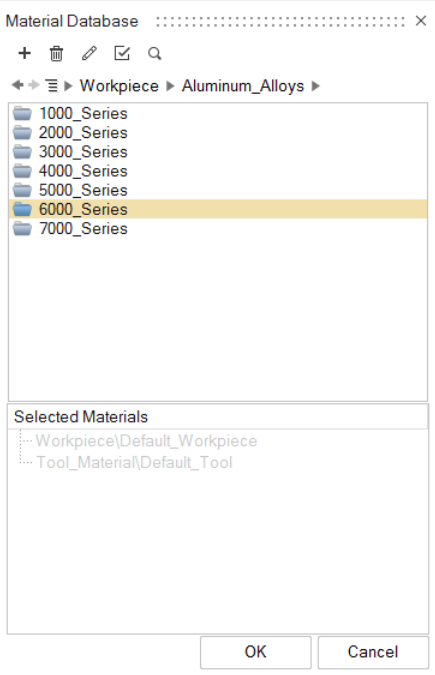

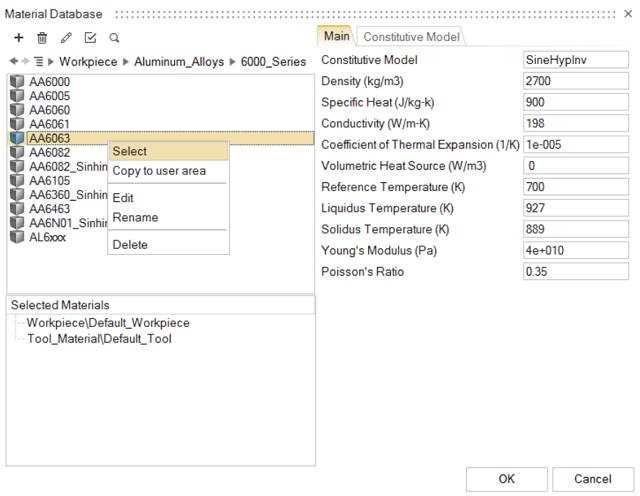

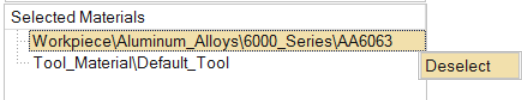

Select the Material

Specify Process Parameters and Simulate

-

Click theSubmit job for analysis icon to run the

simulation.

-

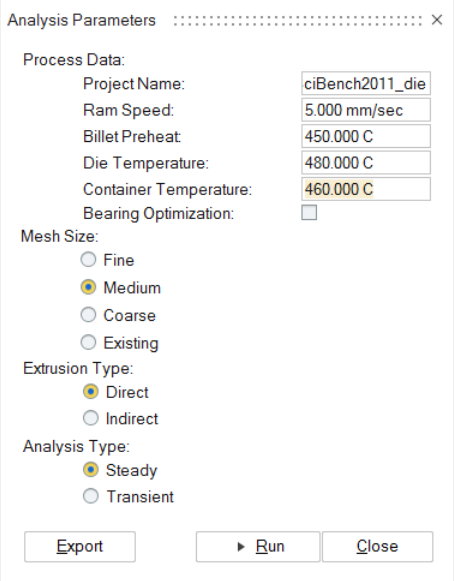

In the Analysis Parameters window that pops up, enter

values as shown.

- Click the Run button.

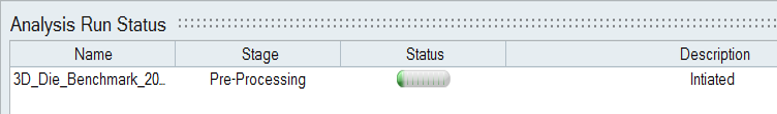

| Status after submitting the job |

|

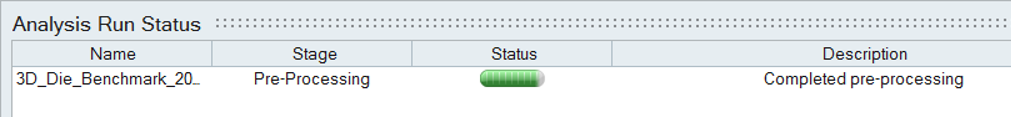

| Status after meshing is completed |

|

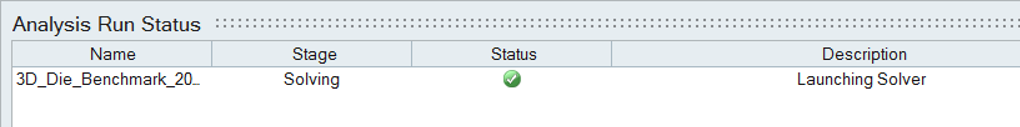

| Status when job is running in the solver |

|