OS-T: 1530 Bumper Impact

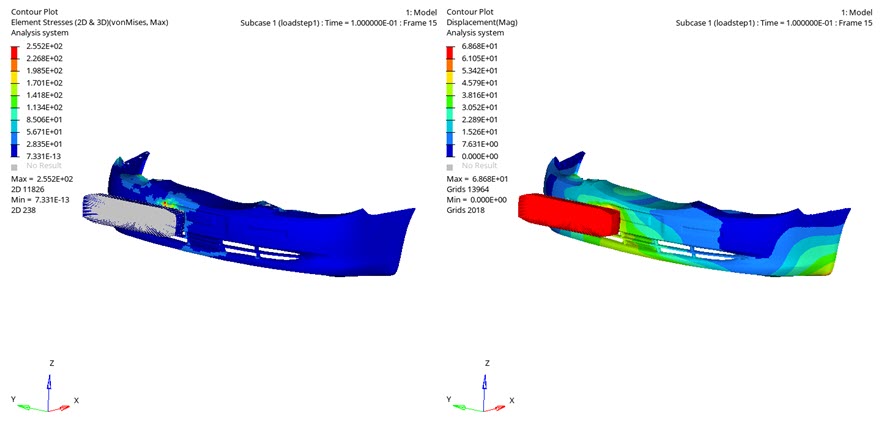

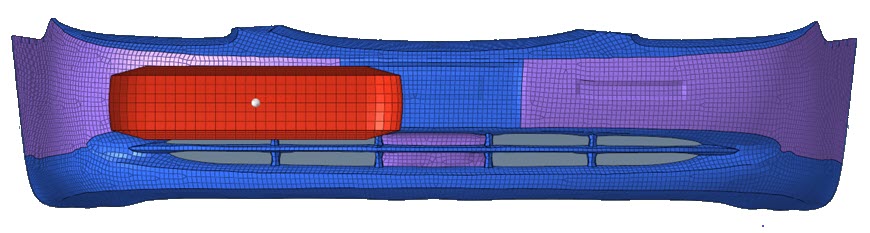

This tutorial demonstrates the setup of a Nonlinear Transient Analysis. In this tutorial, the stopper is defined as rigid.

Figure 1. FE Model with Loadcases and Loadstep

- Import the model into HyperMesh

- Set up nonlinear material.

- Set up nonlinear analysis

- View the results in HyperView

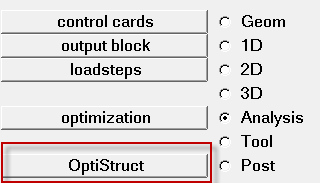

Launch HyperMesh and Set the OptiStruct User Profile

Open the Model

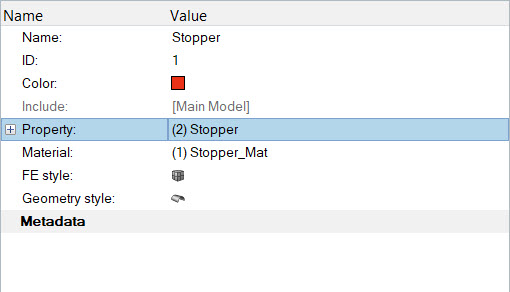

Set Up the Model

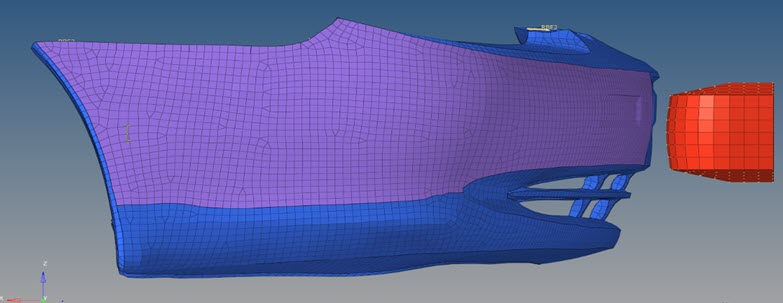

Create TABLES1 Curve

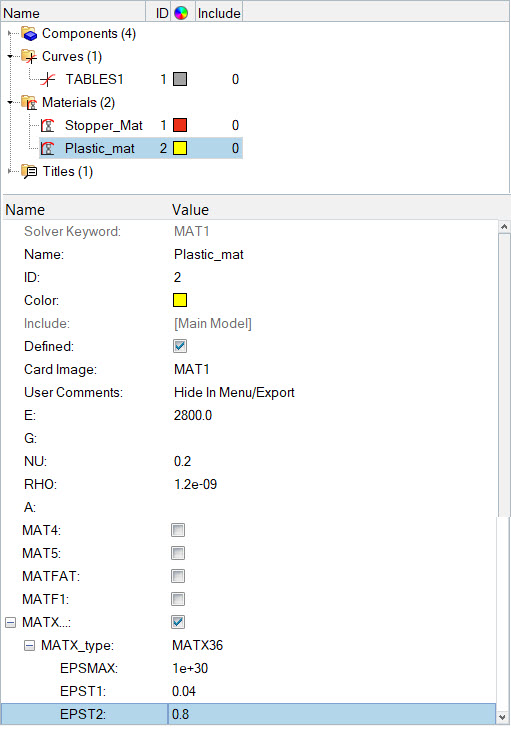

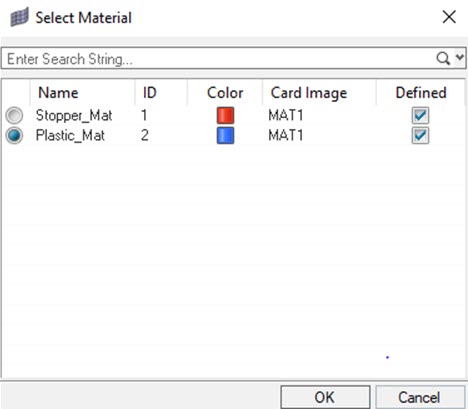

Create the Material

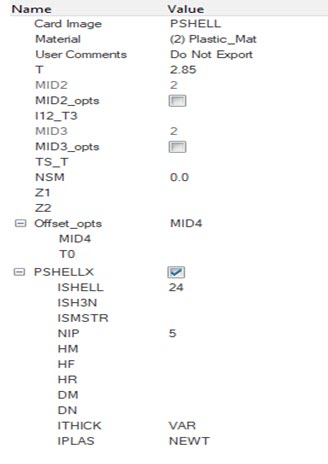

Create the Properties

Create PCONTX Property

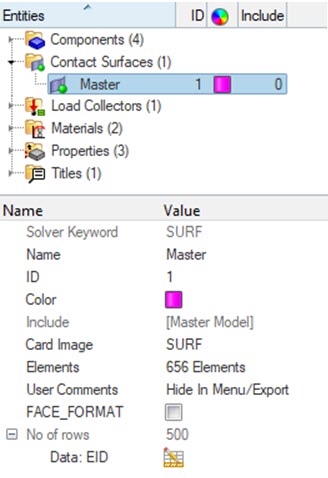

Create Set Segments

The contact surfaces will be defined, which will be used later to define the contact groups.

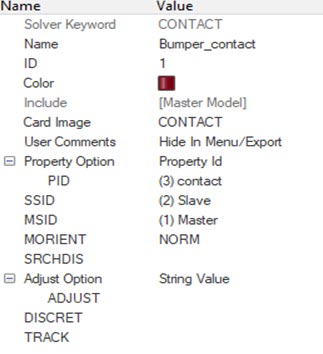

Create Contact Groups

Here the contact groups will be defined.

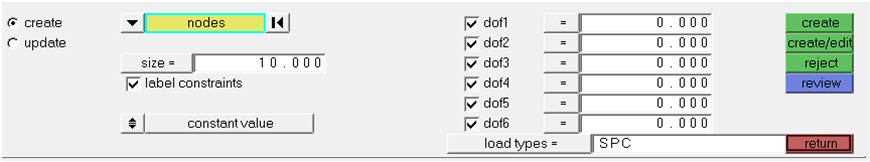

Apply Loads and Boundary Conditions

In the following steps, SPC constraints are applied on the nodes corresponding to the RBE2. Two SPC’s using SPCADD are added.

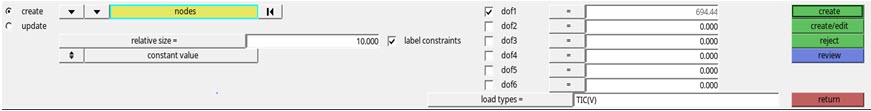

Create SPC's Load Collector

Create the Initial Velocity

Create TSTEP Load Collector

- In the Model Browser, right-click and select .

- For Name, enter TSTEP.

- For Card Image, select TSTEP from the drop-down menu.

- For N, enter 200.

- For DT, enter 0.001.

- Click Close.

Create NLPARM Load Collector

- In the Model Browser, right-click and select .

- For Name, enter NLPARM.

- Click Color and select a color from the color palette.

- For Card Image, select NLPARM from the drop-down menu.

- For NINC, enter 500.

- For DT, enter 0.001.

- For MAXITER, enter 80.

- For CONV, select PW.

- For TTERM, enter 0.1.

- For EPSP, enter 0.001.

- For EPSW, enter 1e-6.

Create NLOUT Load Collector

- In the Model Browser, right-click and select .

- For Name, enter NLOUT.

- For Card Image, select NLOUT from the drop-down menu.

- For NINT, enter 100.

Define Output Control Parameters

- From the Analysis page, select control cards.

- Click on GLOBAL_OUTPUT_REQUEST.

- Below DISPLACEMENT, ELFORCE, STRESS and STRAIN, set Option to Yes.

- Click return twice to go to the main menu.

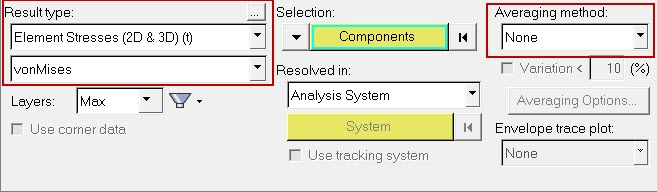

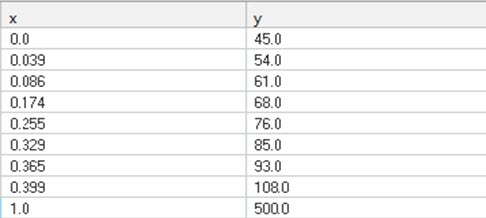

(Contour).

(Contour).