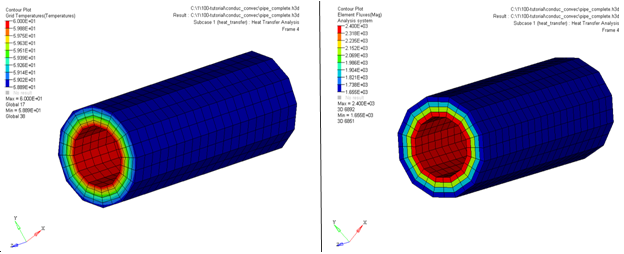

OS-T: 1085 Linear Steady-state Heat Convection Analysis

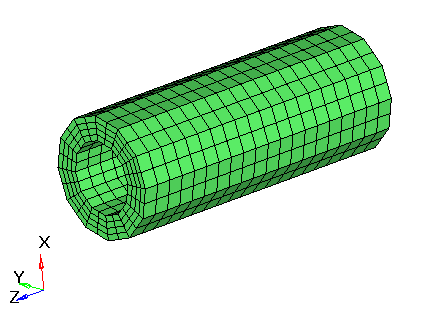

This tutorial performs a heat transfer analysis on a steel pipe.

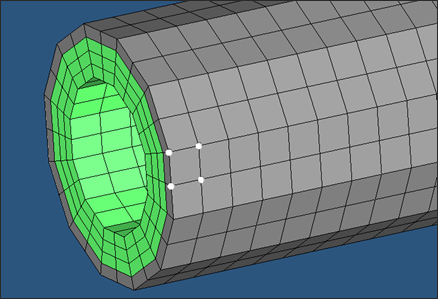

Figure 1. Model Review

Launch HyperMesh and Set the OptiStruct User Profile

Import the Model

Set Up the Model

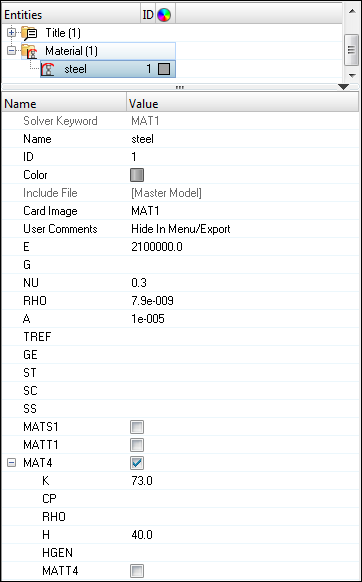

Create Thermal Material and Properties

Link Material and Property to Existing Structure

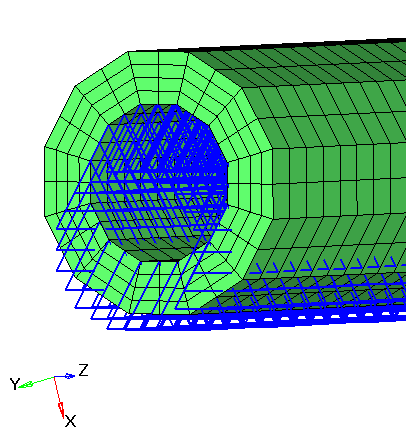

Apply Thermal Loads and Boundary Conditions

In this exercise the thermal boundary conditions are applied on the model and saved in a predefined load collector spc_temp. A predefined node 4679 specifies the ambient temperature. A predefined node set node_temp contains the nodes on the inside surface of the pipe.

Create Temperature on the Inner Surface of the Pipe

Create Ambient Temperature

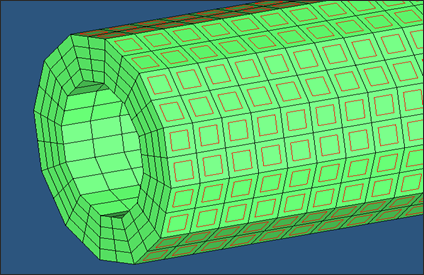

Create CHBDYE Surface Elements

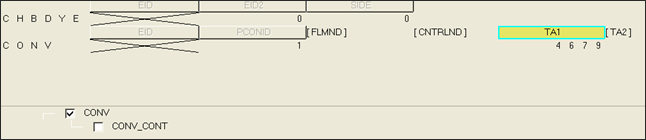

Define Convection Boundary Condition to Surface Elements

Create Heat Transfer Load Step

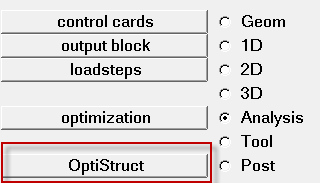

Submit the Job

View the Results

Gradient temperatures and flux contour results for the steady-state heat conduction analysis and the stress and displacement results for the structural analysis are computed from OptiStruct. HyperView will be used to post process the results.

.

.

.

.

to open the

to open the