/FAIL/GURSON

Block Format Keyword A Gurson-Nahshon-Hutchinson failure model describing the damage in terms of void nucleation and growth in metal plasticity.

The modified Gurson formulation adds additional damage accumulation terms for shear dominated loads, specific treatment under compressive loading, and elastic stiffness loss with damage.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/GURSON/mat_ID/unit_ID | |||||||||

| Iloc | |||||||||

| As | Kw | ||||||||

| Rlen | Hchi | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

Definition

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material identifier. (Integer, maximum 10 digits) |

|

| unit_ID | (Optional) Unit Identifier. (Integer, maximum 10 digits) |

|

| First Gurson damage

coefficient. Default = 1.5 (Real) |

||

| Second Gurson damage coefficient,

maximum value = 1.02. Default = 1.0 (Real) |

||

| Iloc | Damage variable accumulation method flag.

(Integer) |

|

| Equivalent plastic strain at void

nucleation. (Real) |

||

| As | Linear void nucleation

slope. (Real) |

|

| Kw | Shear damage growth

coefficient. (Real) |

|

| Critical void volume fraction at

void coalescence. (Real) |

||

| Void volume fraction at ductile

failure. (Real) |

||

| Initial void volume

fraction. (Real) |

||

| Rlen | Radius of non-local variable

influence (Iloc

> 1). (Real) |

|

| Hchi | Non-local penalty parameter

(Micromorphic method only,

Iloc =

2). (Real) |

|

| Mesh convergence element length

target. 5

(Real) |

||

| fail_ID | (Optional) Failure criteria

identifier. (Integer, maximum 10 digits) |

Comments

- The Gurson damage model

may only be used with the elasto-plastic material

/MAT/LAW104. The yield surface definition of the

material law is modified by adding the damage evolution terms:

(1) Where,- ,

- Two Gurson-Tveergard-Needleman parameters.

- Effective damage

- Factor defined as:

- Total void volume fraction that is computed incrementally.

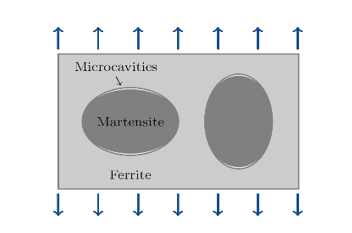

The kinetic equations of the damage factor increments are:- Void nucleation (creation of microcavities), decreasing at low

triaxiality.

(2) Where, is the stress triaxiality defined as:(3)

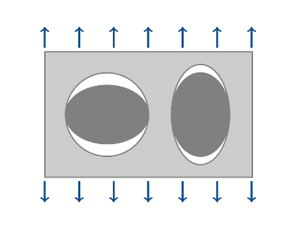

Figure 1. Nucleation of cavities - Void growth at high triaxiality:

(4)

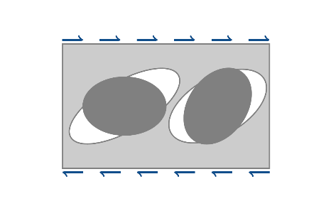

Figure 2. Growth of cavities at high triaxiality - Additional shear void growth at low triaxiality which is shear

dominated:

(5) Where, is a weight function depending on the Lode angle:(6)

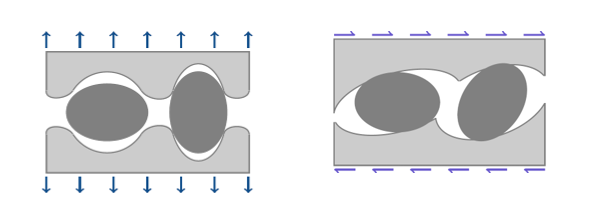

Figure 3. Growth of cavities at low triaxialityTo represent the cavities coalescence when a critical void volume fraction is reached by , the effective damage (which has an influence on the stress computation) is introduced in the model and its expression depends on :(7) Where, is the total void volume fraction at rupture for which .

Figure 4. Coalescence of cavitiesTo take into account the effect of the stiffness loss, a damage variable is computed as:(8) The effective damage is normalized by its rupture value which gives . The stress tensor is then computed as:(9) Where, is the elastic stiffness matrix.

The material fails when the cumulated total damage factor reaches the limit value . The element is then deleted.

- By default

, the damage variable is calculated step by

step using the local plastic strain values at each integration point.

However, one may want to use non-local regularization which offers mesh size

and the mesh orientation independent results (mesh convergence) for all

meshes using the mesh size

less than equal to the maximum value set by

you

. This maximum mesh size

is then the highest mesh size used for which

results are mesh convergent. If one of the non-local formulations is used, , the damage increments depend on a regularized nodal “non-local” plastic strain calculated on the entire mesh. The non-local plastic strain at nodes denoted is computed accounting for its own gradient and its local counterpart computed at the Gauss points following the set of equations:

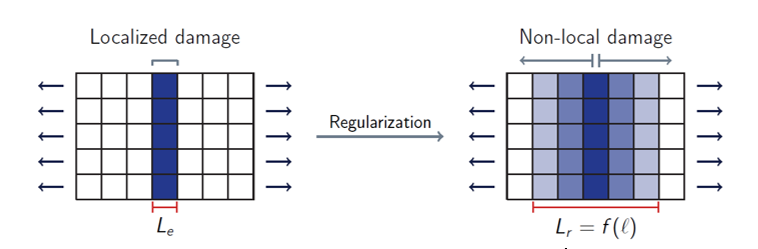

(10) The parameters and are automatically set. You have to set the parameter Rlen (or - Comment 5) which defines a non-local “internal length” which corresponds to a radius of influence in the non-local variable computation. This defines the size of the non-local regularization band (Figure 5).

Figure 5. Non-local regularization principleTo help choose a value for the parameter Rlen, one may follow the following expression:(11) - If

, the non-local Micromorphic method will be

used. For this method, the parameter is required,

Hchi. This

parameter and the non-local plastic strain

are introduced in the constitutive equation

as:

(12) Where, is the classical work-hardening function. This newly defined micromorphic work-hardening function Rchi is introduced in the flow stress computation . The parameter Hchi becomes a penalty parameter and if , then and and so . This method is thermo-dynamically well defined. However, it is hard to identify the input values and it changes the plastic behavior of the model. This is why it is recommended to use the Peerlings method .

- If

, the non-local Peerlings method will be

used. For this method, the parameter

Hchi is used. Only

the non-local length Rlen

is used. This method is simpler than the Micromorphic one. It introduces the

non-local plastic strain in the softening variable kinetic equation (damage

and temperature if thermal effects are considered):

(13) (14) This method is recommended since it is simple to identify the input parameters and does not modify the plastic behavior of the material.

- To set the non-local

length parameter Rlen, you

can choose:

- Directly input the value of Rlen in the input card, if a direct control on this parameter is wanted. In this case, the parameter must be ignored and set to none.

- Input the maximum mesh size for which results have reached mesh convergence. The non-local regularization will then be effective for all mesh sizes such as . In this case Rlen is calculated automatically according to the value of , and the input value of Rlen is ignored. For instance, if you want to get converged and mesh-independent results for a mesh size of 5 mm, mm. In this case, the results will be converged, mesh-size and mesh orientation independent for mm.

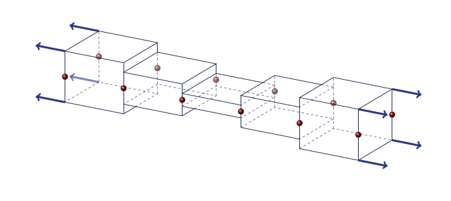

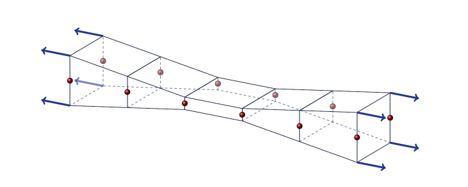

- When a non-local regularization is used for shell elements, an

additional regularization is made on the thickness variation computation

avoiding an additional localization issue. In the common local case (Figure 6), the compatibility of thickness

between shell elements is not ensured due to the lack of kinematic equations

in the z-direction, and the thickness variation is locally computed at Gauss

points. By introducing the non-local plastic strain in the “in-thickness”

strain increment, the compatibility is restored, (Figure 7).

(15) Where, is the non-local plastic multiplier.

Figure 6. Transverse strain incompatibility (local)

Figure 7. Transverse strain compatibility (non-local)Note: This last point implies that the identified parameters can be used on solid and shells, as results will be identical within the same range of stress triaxiality . - To create a specific damage output DAMA in ANIM and H3D files, the

total damage is normalized by its rupture value:

(16)