ACU-T: 4002 Sloshing of Water in a Tank

Prerequisites

This tutorial provides instructions for running a transient simulation of a two-phase flow in a rectangular tank using the level set model. Prior to starting this tutorial, you should have already run through the introductory tutorial, ACU-T: 1000 Basic Flow Set Up, and have a basic understanding of HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

Prior to running through this tutorial, click here to download the tutorial models. Extract ACU-T4002_TankSloshing.hm and bodyForce.c from HyperWorksCFD_tutorial_inputs.zip.

Since the HyperWorks CFD database (.hm file) contains meshed geometry, this tutorial does not include steps related to geometry import and mesh generation.

Problem Description

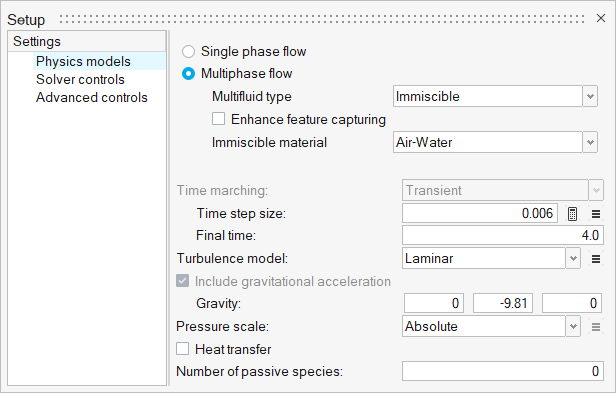

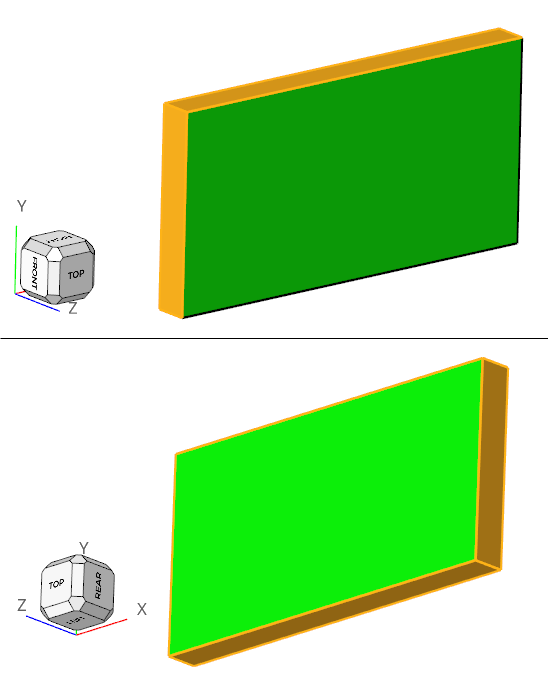

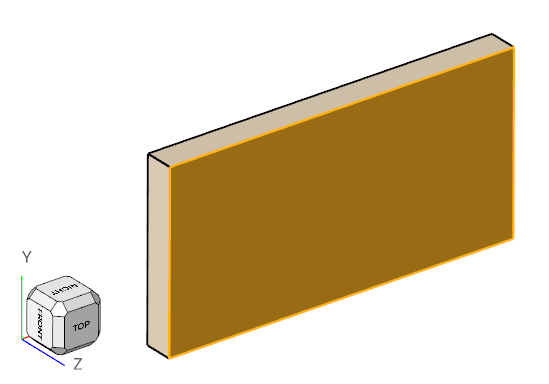

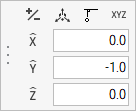

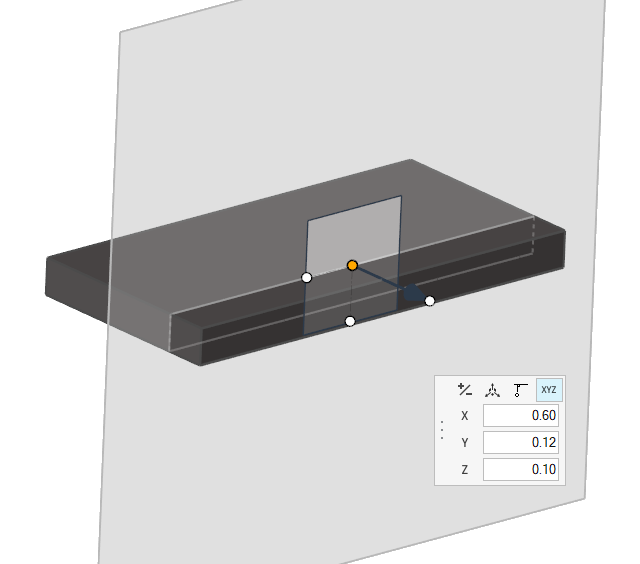

The problem to be solved is shown schematically in the figure below. It consists of a partially filled water tank and from time t=0, water inside the tank is subjected to a sinusoidal varying body force along x-direction and constant gravity along y-direction.

Figure 1.

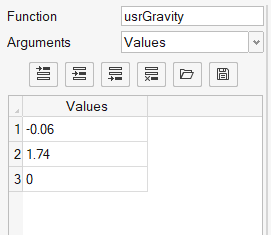

The body force in the x-direction is given by the expression:

- Α = Amplitude of oscillation = -0.06 m

- ω = Frequency of oscillation = = 3.6 rad/sec

- T = Time period of oscillation = 1.74 sec

- φ = Phase difference = 0

Start HyperWorks CFD and Open the HyperMesh Database

Validate the Geometry

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Figure 3.

Set Up the Problem

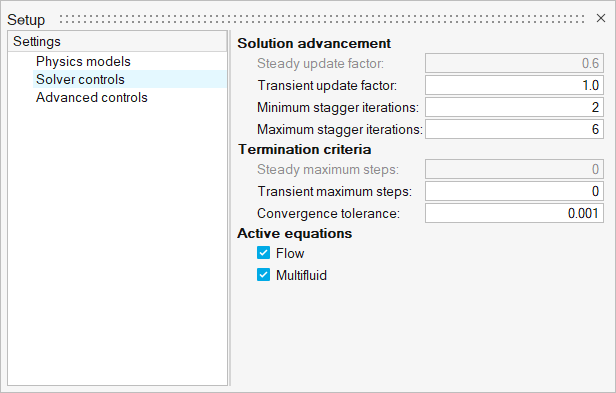

Set Up the Simulation Parameters and Solver Settings

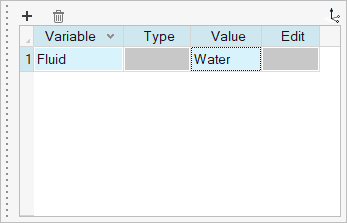

Assign Material Properties

Set the Body Force

Compile the Body Force UDF

-

For Windows:

-

For Linux:

Define Flow Boundary Conditions

Define Nodal Initial Conditions

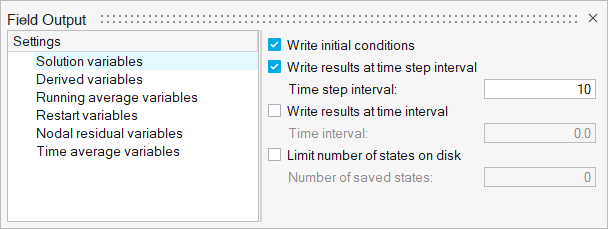

Define Nodal Outputs

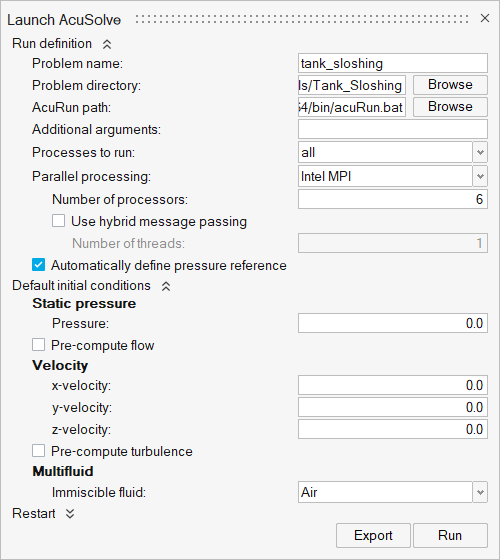

Run AcuSolve

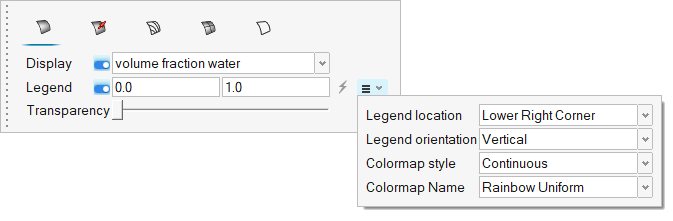

Post-Process the Results with HW-CFD Post

Summary

In this tutorial, you successfully learned how to set up and solve a transient multiphase flow problem involving water sloshing in a tank using HyperWorks CFD and AcuSolve. You also learned how to create a multiphase model using the Level Set method and specify the body force using a user-defined function and then compile the UDF. Once the solution was computed, you post-processed the results using the Post ribbon where you generated an animation of the water sloshing in the tank.