ACU-T: 4003 Freely Falling Water Droplet

Prerequisites

This tutorial introduces you to the workflow for setting up a transient droplet simulation using HyperWorks CFD. Prior to starting this tutorial, you should have already run through the introductory tutorial, ACU-T: 1000 Basic Flow Set Up, and have a basic understanding of HyperWorks CFD and AcuSolve. To run this simulation, you will need access to a licensed version of HyperWorks CFD and AcuSolve.

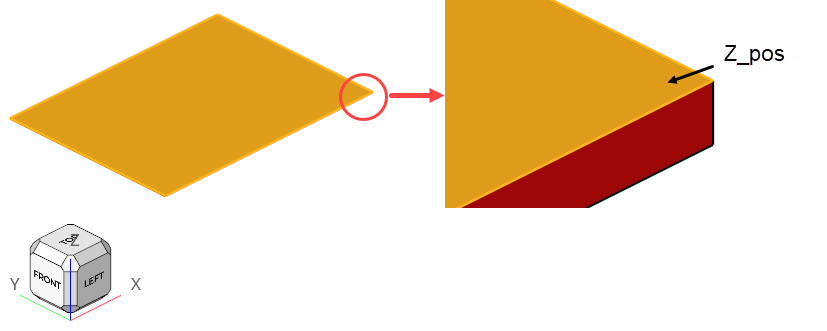

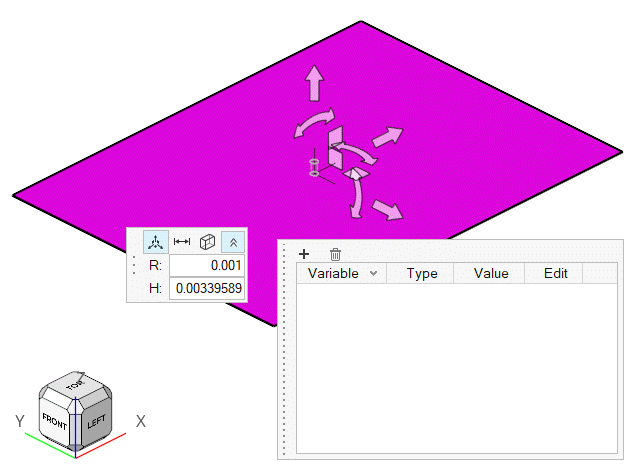

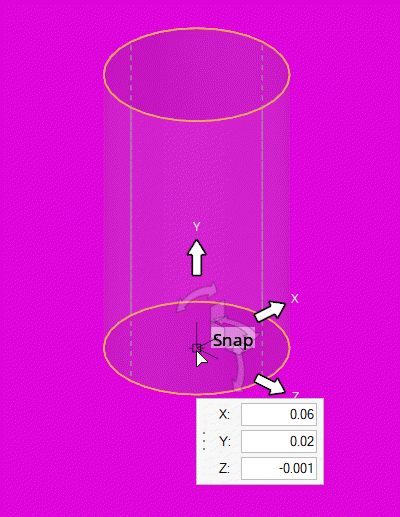

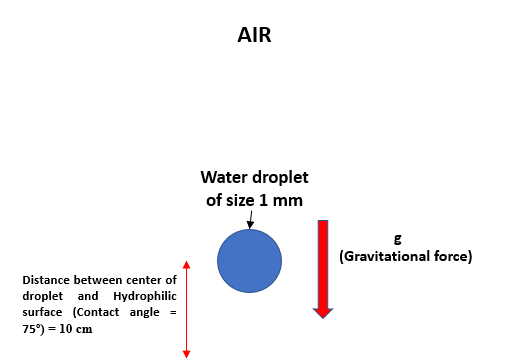

Problem Description

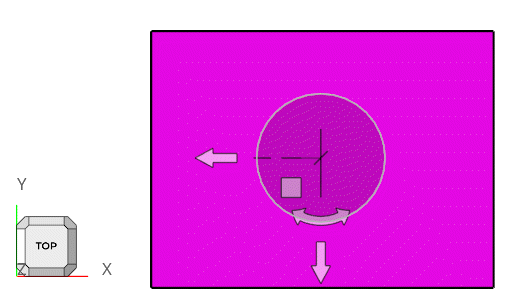

Figure 1.

Start HyperWorks CFD and Open the HyperMesh Database

Validate the Geometry

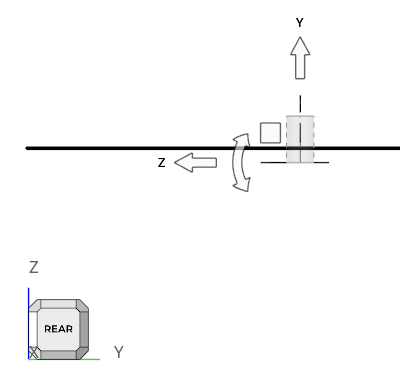

The Validate tool scans through the entire model, performs checks on the surfaces and solids, and flags any defects in the geometry, such as free edges, closed shells, intersections, duplicates, and slivers.

Figure 3.

Set Up Flow

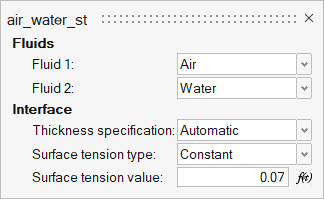

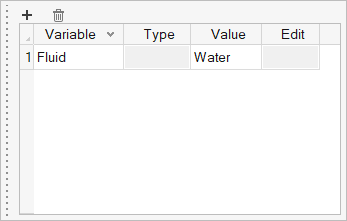

Create Materials

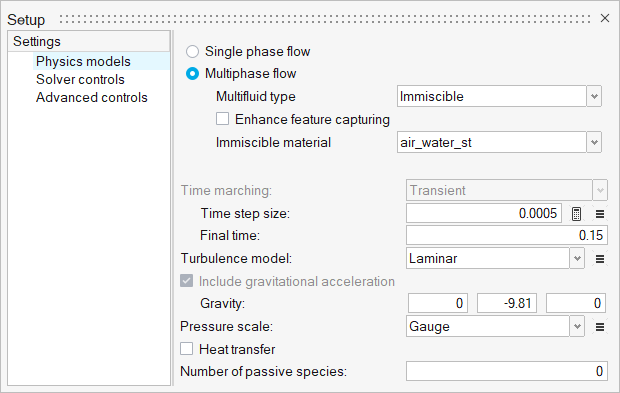

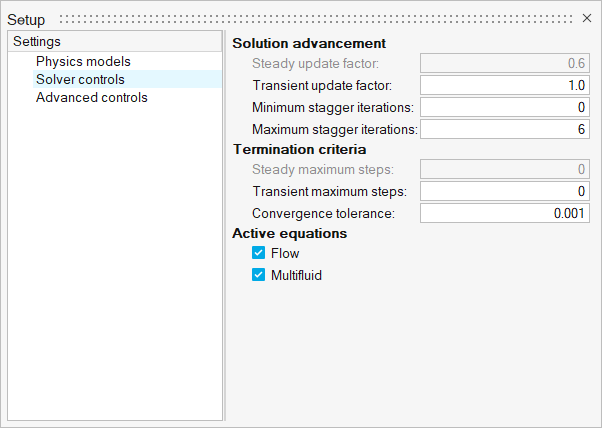

Set Up the Simulation Parameters and Solver Settings

Assign Material Properties

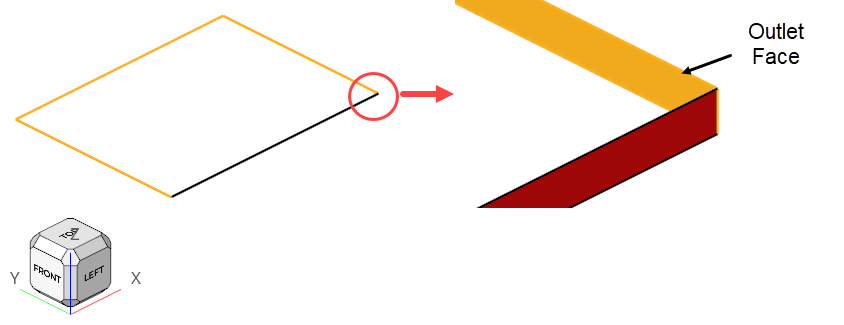

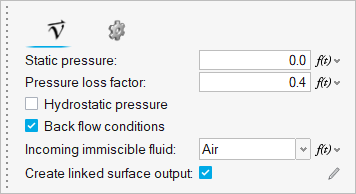

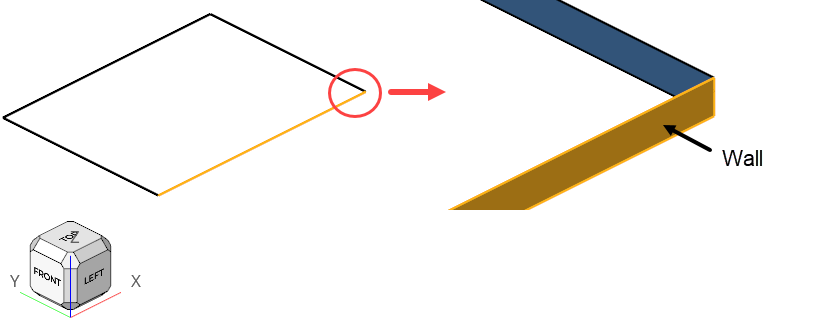

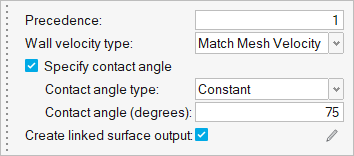

Define Flow Boundary Conditions

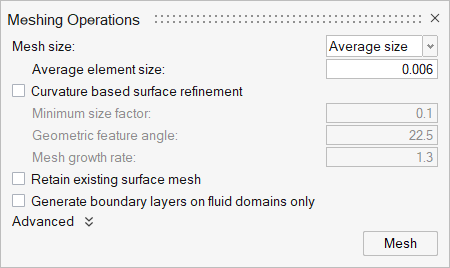

Generate the Mesh

Define Nodal Outputs and Nodal Initial Conditions

In this step, you will define the nodal output frequency and then specify the nodal initial conditions for the water droplet.

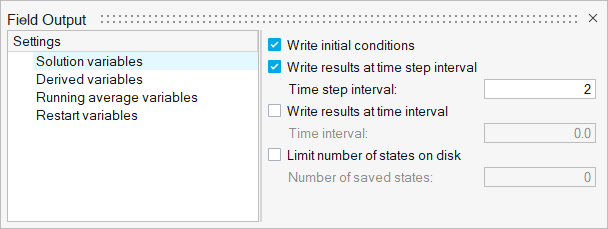

Define Nodal Output Frequency

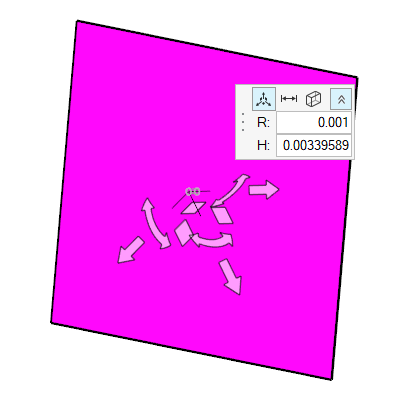

Define Nodal Initial Conditions

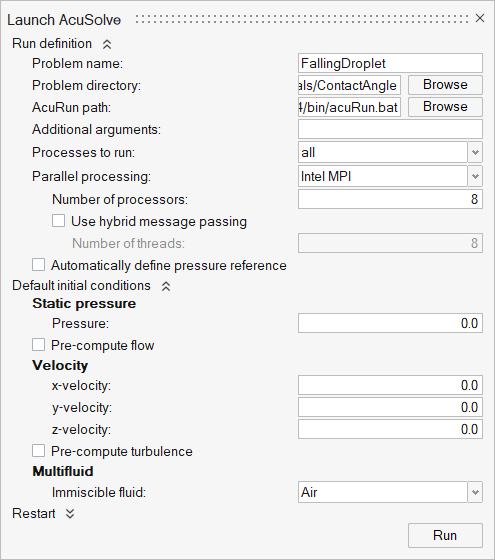

Run AcuSolve

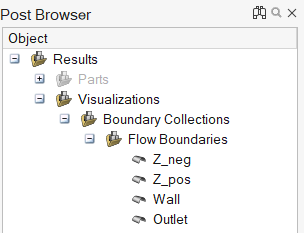

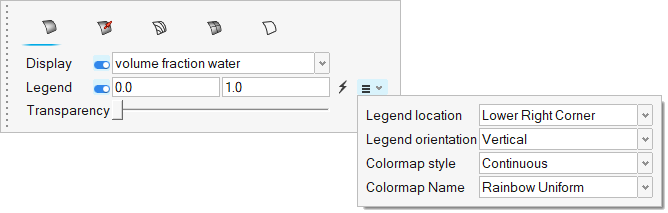

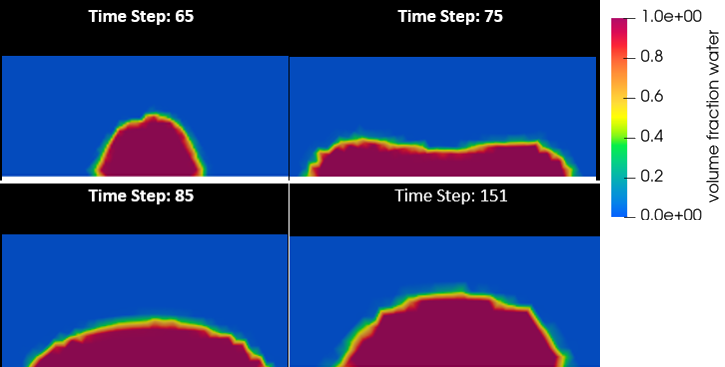

Post-Process the Results with HW-CFD Post

Summary

In this tutorial, you successfully learned how to set up and solve a simulation involving contact angle and surface tension using HyperWorks CFD. You imported the geometry and then defined the simulation parameters and flow boundary conditions. Once the solution was computed, you used HyperWorks CFD Post to create the contours of volume fraction of water