/MAT/LAW113 (SPR_BEAM)

Block Format Keyword This beam type spring material works as a beam element with six independent modes of deformation. This spring accounts for nonlinear stiffness, damping and different unloading.

Deformation, force, and energy-based failure criteria are available. This material must be assigned to a /PART that references the spring property /PROP/TYPE23 (SPR_MAT).

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW113/mat_ID/unit_ID or /MAT/SPR_BEAM/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| Ifail | Ileng | Ifail2 | |||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K1 | C1 | A1 | B1 | D1 | |||||

| fct_ID11 | H1 | fct_ID21 | fct_ID31 | fct_ID41 | |||||

| F1 | E1 | Ascale1 | Hscale1 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K2 | C2 | A2 | B2 | D2 | |||||

| fct_ID12 | H2 | fct_ID22 | fct_ID32 | fct_ID42 | |||||

| F2 | E2 | Ascale2 | Hscale2 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K3 | C3 | A3 | B3 | D3 | |||||

| fct_ID13 | H3 | fct_ID23 | fct_ID33 | fct_ID43 | |||||

| F3 | E3 | Ascale3 | Hscale3 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K4 | C4 | A4 | B4 | D4 | |||||

| fct_ID14 | H4 | fct_ID24 | fct_ID34 | fct_ID44 | |||||

| F4 | E4 | Ascale4 | Hscale4 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K5 | C5 | A5 | B5 | D5 | |||||

| fct_ID15 | H5 | fct_ID25 | fct_ID35 | fct_ID45 | |||||

| F5 | E5 | Ascale5 | Hscale5 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| K6 | C6 | A6 | B6 | D6 | |||||

| fct_ID16 | H6 | fct_ID26 | fct_ID36 | fct_ID46 | |||||

| F6 | E6 | Ascale6 | Hscale6 | ||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| Fcut | Fsmooth | ||||||||

| c1 | n1 | ||||||||

| c2 | n2 | ||||||||

| c3 | n3 | ||||||||

| c4 | n4 | ||||||||

| c5 | n5 | ||||||||

| c6 | n6 | ||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Density. (Real) |

||

| Ifail | Failure criteria.

(Integer) |

|

| Ileng | Input per unit length

flag. 4

5

(Integer) |

|

| Ifail2 | Failure model flag.

(Integer) |

|

| Ki | If

fct_ID1i =

0: Linear loading and unloading stiffness. If fct_ID1i ≠ 0: Only used as unloading stiffness for elasto-plastic springs. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Ci | Damping. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Ai | Nonlinear stiffness

function scale factor. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Bi | Scale factor for

logarithmic rate effects. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 0.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Di | Scale factor for

logarithmic rate effects. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| fct_ID1i | Function identifier

defining nonlinear stiffness

.

If Hi =4: Function defines upper yield curve. If Hi =8: Function is mandatory and defines the force or moment versus spring length. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Integer) |

|

| Hi | Spring Hardening flag for

nonlinear spring.

= 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Integer) |

|

| fct_ID2i | Function identifier

defining force or moment as a function of spring velocity,

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Integer) |

|

| fct_ID3i | Function identifier. If Hi =4: Defines lower yield curve. If Hi =5: Defines residual displacement or rotation versus maximum displacement or rotation. If Hi =6: Defines nonlinear unloading curve. If Hi =7: Defines nonlinear unloading curve. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Integer) |

|

| fct_ID4i | Function identifier for

nonlinear damping,

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Integer) |

|

| Negative translation

failure limit. = 1, 2, 3 are translation DOF. Default = -1030 (Real) |

||

| If Ifail2 = 0 or 1: Failure displacement. | ||

| If Ifail2 = 2: Failure force. | ||

| If Ifail2 = 3: Failure internal energy. | ||

| Negative rotational

failure limit. = 4, 5, 6 are rotation DOF. Default = -1030 (Real) |

||

| If Ifail2 = 0 or 1: Failure rotation. | ||

| If Ifail2 = 2: Failure moment. | ||

| If Ifail2 = 3: Failure internal energy. | ||

| Positive translation

failure limit. = 1, 2, 3 are translation DOF. Default = -1030 (Real) |

||

| If Ifail2 = 0 or 1: Failure displacement. | ||

| If Ifail2 = 2: Failure force. | ||

| If Ifail2 = 3: Failure internal energy. | ||

| Positive rotational

failure limit. = 4, 5, 6 are rotation DOF. Default = -1030 (Real) |

||

| If Ifail2 = 0 or 1: Failure rotation. | ||

| If Ifail2 = 2: Failure moment. | ||

| If Ifail2 = 3: Failure internal energy. | ||

| Fi | Abscissa scale factor for

the damping functions for the

and

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Ei | Ordinate scale factor for

the damping function

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Ascalei | Abscissa scale factor for

the stiffness function

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Hscalei | Ordinate scale factor for

the damping function

. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

if

= 1, 2, 3 if = 4, 5, 6 |

| Reference translational

velocity. Default = 1.0 (Real) |

||

| Reference rotational

velocity. Default = 1.0 (Real) |

||

| Fcut | Strain rate cutting

frequency. Default = 1030 (Real) |

|

| Fsmooth | Smooth strain rate flag.

(Integer) |

|

| ci | Relative velocity coefficient. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 0.0 (Real) |

|

| If Ifail2 = 0 or 1: Failure displacement or rotation. |

if

= 1, 2, 3 if = 4, 5, 6 |

|

| If Ifail2 = 2: Failure force or moment. |

if

= 1, 2, 3 if = 4, 5, 6 |

|

| If Ifail2 = 3: Coefficient for failure internal energy. | ||

| ni | Relative velocity exponent. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 0.0 (Real) |

|

| Failure scale factor. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 1.0 (Real) |

||

| Exponent. = 1, 2, 3 are translation DOF. = 4, 5, 6 are rotation DOF. Default = 2.0 (Real) |

Example

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 1. LOCAL_UNIT_SYSTEM:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/2

units for material and property

Mg mm s

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/PROP/SPR_MAT/26/2

SPOTWELD_NO_RUPTURE

# Imass Volume Inertia skew_ID sens_ID Isflag

2 1 6.55E-6 0 0 0

/MAT/LAW113/26/2

SPOTWELD_NO_RUPTURE

2E-6

# Ifail Ileng Ifail2

# K1 C1 A1 B1 D1

100000 0 0 0 0

# fct_ID11 H1 fct_ID21 fct_ID31 fct_ID41 delta_min1 delta_max1

1 1 0 0 0 0 .5E-1

# F1 E1 Ascale1 Hscale1

0 0 0 0

# K2 C2 A2 B2 D2

500000 0 0 0 0

# fct_ID12 H2 fct_ID22 fct_ID32 fct_ID42 delta_min2 delta_max2

2 1 0 0 0 -.5E-1 .5E-1

# F2 E2 Ascale2 Hscale2

0 0 0 0

# K3 C3 A3 B3 D3

500000 0 0 0 0

# fct_ID13 H3 fct_ID23 fct_ID33 fct_ID43 delta_min3 delta_max3

2 1 0 0 0 -.5E-2 .5E-2

# F3 E3 Ascale3 Hscale3

0 0 0 0

# K4 C4 A4 B4 D4

5000000 0 0 0 0

# fct_ID14 H4 fct_ID24 fct_ID34 fct_ID44 delta_min4 delta_max4

0 1 0 0 0 -.015 .015

# F4 E4 Ascale4 Hscale4

0 0 0 0

# K5 C5 A5 B5 D5

5000000 0 0 0 0

# fct_ID15 H5 fct_ID25 fct_ID35 fct_ID45 delta_min5 delta_max5

0 1 0 0 0 -.015 .015

# F5 E5 Ascale5 Hscale5

0 0 0 0

# K6 C6 A6 B6 D6

5000000 0 0 0 0

# fct_ID16 H6 fct_ID26 fct_ID36 fct_ID46 delta_min6 delta_max6

0 1 0 0 0 -.015 .015

# F6 E6 Ascale6 Hscale6

0 0 0 0

# V0 Omega0 F_cut Fsmooth

0 0 0 0

# C n alpha beta

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 7. FUNCTIONS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/1

spotweld tensile function

# X Y

-250.0 -8250.0

-0.25 -8250.0

0.0 0.0

0.25 8250.0

250.0 8250.0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/FUNCT/2

Spotweld shear function

# X Y

-250.0 -25000.0

-0.25 -25000.0

0.0 0.0

0.25 25000.0

250.0 25000.0

#enddataComments

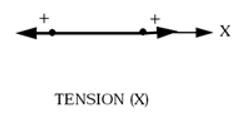

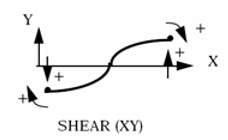

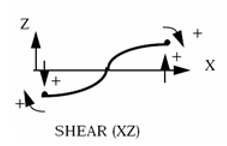

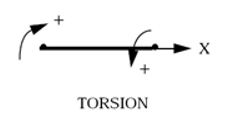

- When used with /PROP/TYPE23 (SPR_MAT), this material law has the same behavior as spring property /PROP/SPR_BEAM.

- Inputs repeated for

each degree of freedom (DOF)

are defined with the following directions:

- =1: tension/compression

- =2: shear xy

- =3: shear xz

- =4: torsion

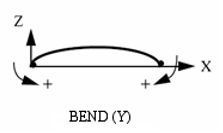

- =5: bending y

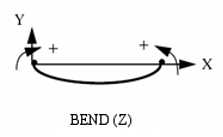

- =6: bending z

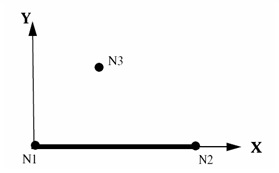

- The spring's

direction is defined using nodes N1 and N2 of

the spring.If the node of the spring N3 is defined, the spring's direction is defined using nodes N1 and N3 of the spring. N3, N2, and N1 should not be in a line.

Figure 1.- The

direction is:

(1) - If node N3 is not defined in the element input, and skew system is

defined in the /PROP/TYPE23 (SPR_MAT) input, the

direction is:

(2) - If neither node N3 nor skew system are defined in input, the

direction is:

(3)

(4) Finally, direction is found as:(5) - The

direction is:

- If Ileng = 1, the spring

stiffness properties are related on the initial spring length. The input should

be entered as:Each spring will then have the following properties in the model:

- and

- Spring values entered in the spring property fields

- and

- Spring’s actual physical mass, inertia, stiffness and damping

- Initial spring length which is the distance between node N1 and N2 of the spring

- Failure values entered as engineering strain

- Force and moment

computation. For additional information, refer to Stiffness Formulation in the User Guide.

If Ileng = 0, translational DOFs =1,2,3 - use displacement to determine spring forces and use rotational angle in radians for rotational DOFs =4,5,6 to determine spring moments.

The values of forces and moments in the spring are computed as:- Linear spring:

with =1,2,3

with =4,5,6

- Nonlinear spring:

with =1,2,3

with =4,5,6

Where,- (with ) is the difference between the current length and the initial length of the spring element for corresponding translational DOF.

- is the relative angle for corresponding rotational DOF in radians.

- For linear springs, and are zero functions and , , and are not taken into account.

- If stiffness function or is requested, then is used as a slope for unloading only.

- If is lower than the maximum slop of function or ( is not consistent with the maximum slope of the curve), is set to the maximum slope of the curve.

If Ileng = 1, translational DOFs =1,2,3 - use engineering strain (elongation per unit length) to determine spring forces and use rotational per unit length for rotational DOFs =4,5,6 to determine spring moments. Spring parameters are related to initial spring length.

The forces and moments in the spring are computed as:- with =1,2,3

- with =4,5,6

Where,- Engineering strain

- Rotation divided by the original spring length

- Linear spring:

- Time step

calculation.

- Time step for translational DOF is computed as:

(6) with =1, 2, 3

- Time step for rotational DOF is computed as:

(7) with =4, 5, 6

Where,with =1, 2, 3 and =4, 5, 6 and is used as spring time step.

- Time step for translational DOF is computed as:

- Failure criteria:

- For uni-directional failure criteria Ifail=0, the spring

fails as soon as one of the criteria is met in one

direction:

(8) or(9) with and being the failure limits in direction =1,2,3(10) or(11) with and being the failure limits in direction =4,5,6

For each direction (or ) should be negative and (or ) should be positive. If the values are zero, then no failure will be considered.

- For multi-directional failure criteria Ifail=1, the spring

fails when the following criteria is fulfilled:

(12) - For "old" displacement formulation (Ifail2 = 0), the coefficients and are equal to 1.0 and 2.0, respectively.

- The new displacement formulation

(Ifail2

=1) allows to model velocity dependent failure limit for

translational DOF:

(13) with =1,2,3(14) with =4,5,6

Where, or is the static displacement failure limit (Lines 5, 8 and 11), and is the reference velocity.

Where, or is the static rotation failure limit (Lines 14, 17 and 20), and is the reference velocity.

Relative velocity coefficients, (with =1,2,3) have the units of displacement and (with =4,5,6) have the units of rotation.

- Force or moment failure criteria is activated with

Ifail2=2:

(15) with =1,2,3 for force criteria(16) with =4,5,6 for moment criteria

Where, or is the static failure limit force (Lines 5, 8, and 11) and is the reference velocity.

Where, or is the static failure limit moment (Lines 14, 17 and 20), and is the reference velocity.

Relative velocity coefficients, (with =1,2,3) have the units of force and (with =4,5,6) have the units of momentum.

- Energy failure criteria is activated with

Ifail2=

3:

(17) with =1,2,3

(18) with =4,5,6

Where, is the static failure limit translational energy (Lines 5, 8, and 11) and is the reference velocity.

Where, is the static failure limit rotational energy (Lines 14, 17 and 20), and is the reference velocity.

In this case, the displacement values are replaced by positive failure energy values and the rotation values are replaced by positive failure energy values.

Relative velocity coefficients, have the units of energy.

- For uni-directional failure criteria Ifail=0, the spring

fails as soon as one of the criteria is met in one

direction:

- Spring elements with sensor activation or deactivation are mainly used in the pretension models.