Straight Line Acceleration

A Straight Line Acceleration event simulates a vehicle accelerating at a constant rate in a straight line. The event is designed to characterize the chassis behavior during acceleration. A drive torque controller applies a controlled torque to the vehicle drivetrain to maintain the requested acceleration. Output requests are included to measure the vehicle behavior, tire response and other common vehicle system metrics. A plot template is available to plot the results.

A Proportional-Differential torque controller is used to provide a torque to match the requested acceleration. The vehicle does not have a gear shift mechanism or engine torque map included and as a result, cannot be used to predict vehicle performance, such as 0-60 times.

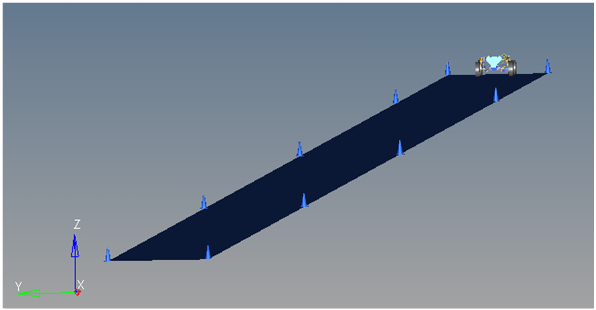

Figure 1. Straight Line Acceleration event

Figure 2. Top View of a Straight Line Acceleration event

Description

This event is designed to work with a full vehicle model that has been built through the MotionView Assembly Wizard. The event should attach to the model automatically when added through the Task Wizard. It can be used with models built manually, as long as the attachment scheme in the event is strictly followed.

The Straight Line Acceleration event is used to accelerate the vehicle in a straight line. The event is designed to characterize the vehicle behavior due to steady state acceleration. Vehicle pitch and suspension reaction to acceleration are the typical responses measured during the event. The steering wheel is held fixed during the event.

The torque controller used to accelerate the vehicle applies an action-reaction torque between the engine and the drivetrain in the model. If a drivetrain is not included, the torque is applied at the differential input shaft and is reacted on the body. Include the drivetrain for the most reasonable simulation results.

The initial vehicle velocity and desired acceleration can be modified via the event form.

Nine types of modeling element containers are used to define the event (see below). Two sub-systems (output requests and a drive torque controller) are also included in the event.

Attachments

The event uses the standard event attachment. The attachments resolve automatically if the model is built through the Model Wizard. The attachments contain the minimum data the event needs to run the analysis. The attachments are standard for most events.Curves

The event uses the standard event attachment. The attachments resolve automatically if the model is built through the Model Wizard. The attachments contain the minimum data the event needs to run the analysis. The attachments are standard for most events.Datasets

One dataset is used in the system, which contains the data used to describe the Straight line acceleration event. The event allows you to set the initial Vehicle velocity, lane graphics width, and desired acceleration. The wheel rotational velocities and ground height are calculated values and should not be changed.Forms

The Form is the only place that you should change the Straight line acceleration event. Initial Vehicle velocity and the desired acceleration are the parameters that can be changed. The lane width is not included on the Form and as a result, must be edited in the dataset.Graphics

Eleven graphics are defined in the event. The graphics define the cones and the straight road graphics and should not require any user input. A full description of the graphics can be found here.

The road graphics are included to illustrate the path being driven and are defined parametrically using the data in the Straight line acceleration Form. All road graphics are used to illustrate the lane dimensions but they are not of the actual road used for calculating tire forces. Road graphics should never require editing unless the event is being fundamentally changed.

Joints

A ball joint is included in the Straight line acceleration event. The joint attaches a dummy body to the steering rack. The joint is included to make certain events work in ADAMS. Attach the dummy body to the steering rack if building a model manually.Markers

Five markers are included in the Straight line acceleration event. The path origin is the origin of all graphics and is parametrically defined to be the CG of the vehicle body. The markers refer to points and the points contain the parametric logic that define the graphics.

The path outline markers point to the Path Outline points for their XYZ location. The markers are used to define the lane graphics. None of the markers should require any user input.

Motions

Three motions are included in the event. The steering motion is used in the template which gives the input for the vehicle to steer and acts on a translational joint that connects the steering rack to the dummy body.

The Front and Rear Wheel Motions act on the wheel spindle revolute joints that connect the wheel hub to the knuckle. The motion is initially zero (fixing the wheels to the knuckle) so the model converges statically. The wheel locking motions are deactivated after the static analysis to allow the tires to rotate during the dynamic simulation.

Points

Fifteen points are defined in the event. All points are used to create the lane graphics and graphics for the cones used to illustrate the lanes. The points contain parametric logic to define their X, Y, and Z locations. You should not need to modify any points.Templates

A template is included in the Straight line acceleration event task. The template is solver specific and only the MotionSolve template is documented. The template is inserted in the solver deck after the </Model> command and controls the execution of the event.

The template contains commands that control data output files, modify the behavior of the vehicle during the event, and terminate the event. In this event, the following actions are defined in the event:

The four wheel motions fixing the wheels to the knuckle are turned off after static equilibrium.

The clamp's two JPRIM clamps holding the body to ground are released.

The event end time of 4 seconds is set.

The event template is written in the XML format.

<ResOutput

angle_type = "YPR"

/>

<ResOutput

mrf_file = "TRUE"

/>

<ResOutput

plt_file = "TRUE"

/>

<H3DOutput

switch_on = "TRUE"

increment = "1"

/>

<ResOutput

abf_file = "TRUE"

/>

<!--Initial static analysis -->

<Simulate

analysis_type = "Static"

end_time = "0.0"

/>

<Deactivate

element_type = "MOTION"

element_id = "{mot_frnt_wheel.l.idstring}"

/>

<Deactivate

element_type = "MOTION"

element_id = "{mot_frnt_wheel.r.idstring}"

/>

<Deactivate

element_type = "MOTION"

element_id = "{mot_rear_wheel.l.idstring}"

/>

<Deactivate

element_type = "MOTION"

element_id = "{mot_rear_wheel.r.idstring}"

/>

<Deactivate

element_type = "JPRIM"

element_id = "{j_clamp_1_body.idstring}"

/>

<Deactivate

element_type = "JPRIM"

element_id = "{j_clamp_2_body.idstring}"

/>

{if (an_accel_event.ds_accel.initial_condition.ival==1)}

<UserProgramControl

usrsub_param_string = "user(100,{Global_Frame.id},-{an_accel_event.ds_accel.veh_vel.value*447.04})"

usrsub_dll_name = "mbdtire"

usrsub_fnc_name = "SETIC"

/>

<UserProgramControl

usrsub_param_string = "user(635,{an_accel_event.ds_accel.veh_vel.value*447.04})"

usrsub_dll_name = "mbdtire"

usrsub_fnc_name = "SETWIC"

/>

{endif}

<Simulate

analysis_type = "Transient"

end_time = "4"

print_interval = "0.01"

/>

<Stop/>