测试编号:VNL06求出受力矩作用的悬臂梁的弹性核心和最大位移。

定义

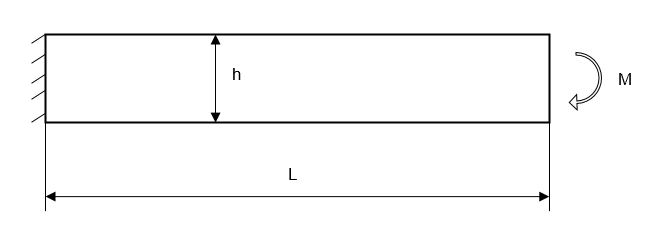

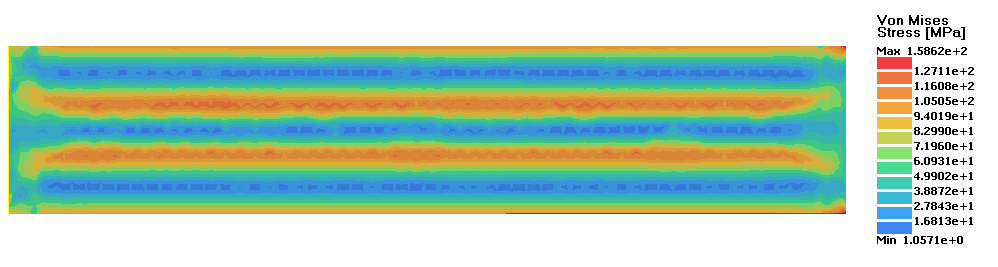

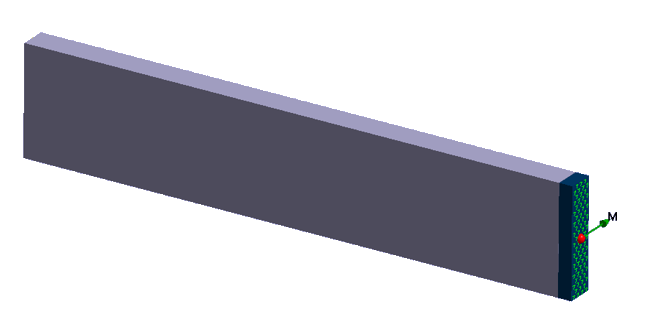

Figure 1.

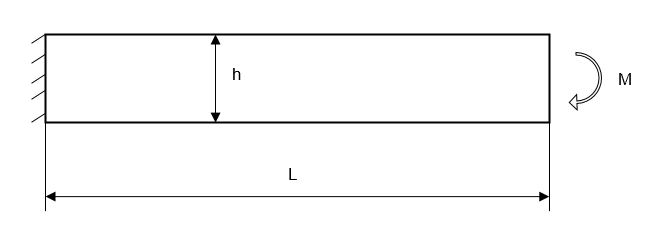

梁尺寸为 b x h x L。

其中,

- 尺寸

- 值

- b

- =10 mm

- h

- =40 mm

- L

- =200 mm

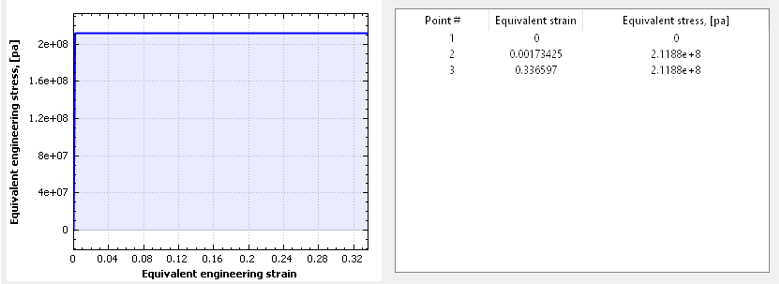

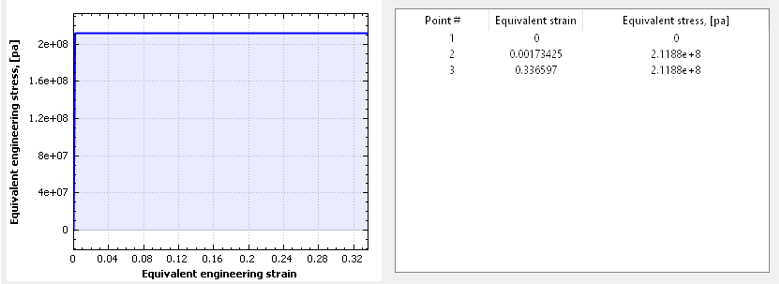

梁的材料为刚性塑性,具有应变-应力曲线 (

Figure 2)。

Figure 2.

材料属性为:

- 属性

- 值

- 屈服应力

-

= 2.1188e+8 Pa

- 屈服应变

-

= 1.73425e-3

- 泊松比

- 0

该研究是针对以下力矩

值进行的:776.893 N*m and 847.518 N*m

参考解

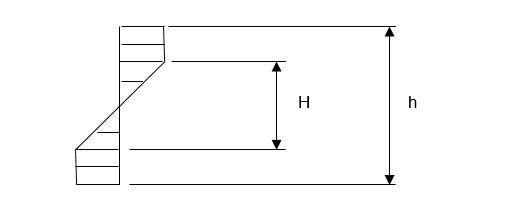

塑性梁弯曲理论假定梁材料中存在两个区域:梁外层的塑性区和梁中心线的弹性核心区。

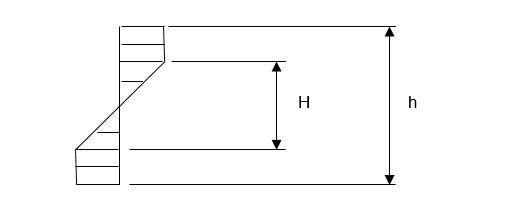

Figure 3. 未硬化材料的相应应力分布

所施加的力矩

梁中弹性核心尺寸

之间的关系。

(1)

其中,

是量厚度。

最大挠度:

(2)

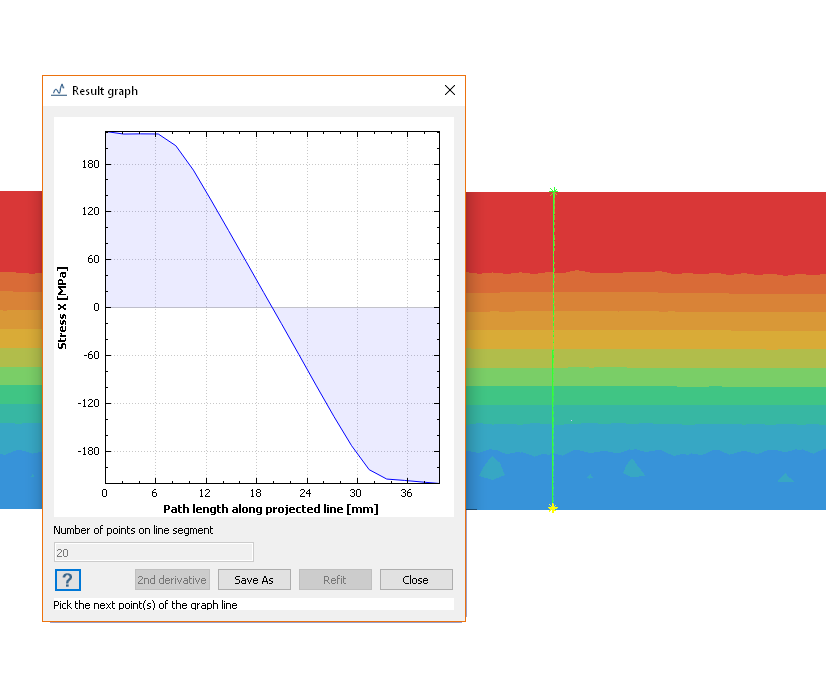

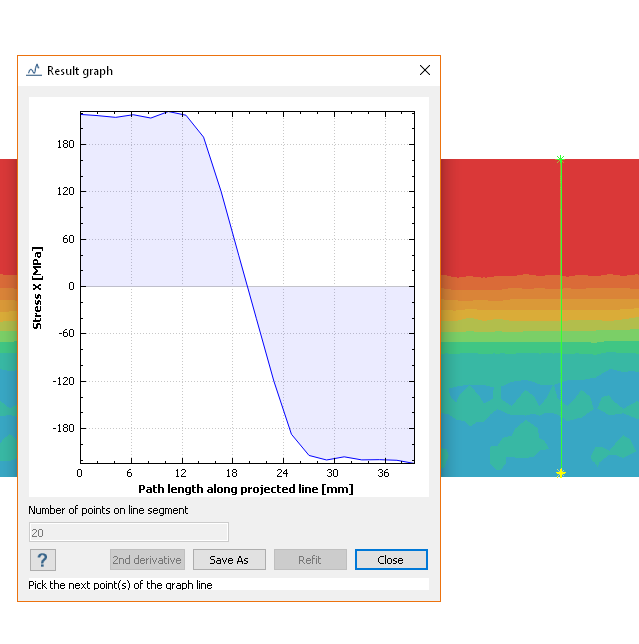

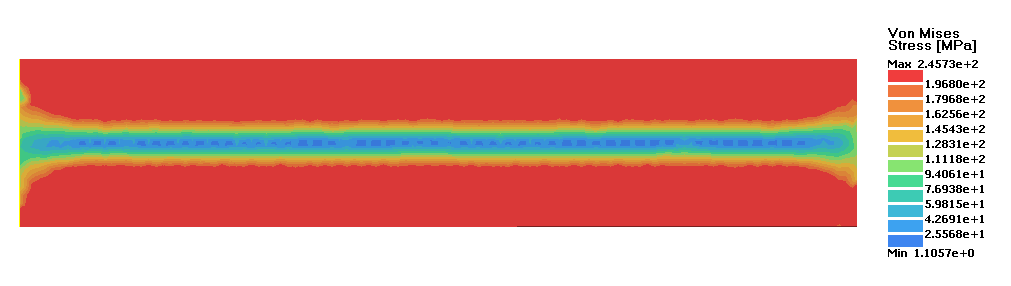

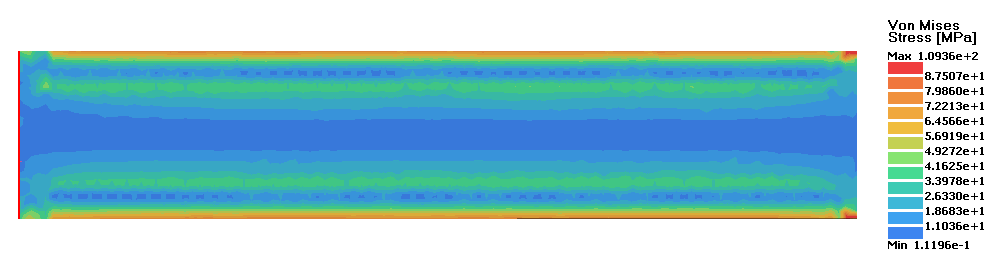

结果

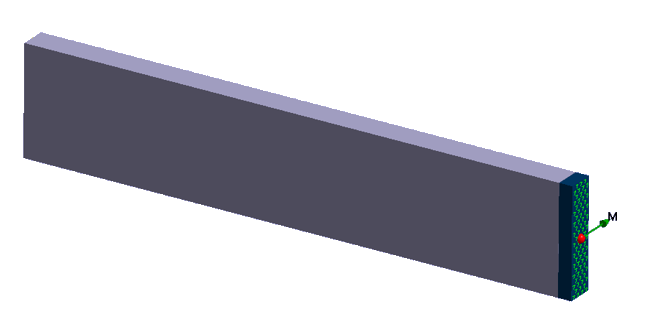

塑性梁的弯曲理论是基于平截面在变形过程中保持平面的假设。为了尽可能接近这一基本假设,将问题建模为两个实体的集合。一个实体表示梁本身,其材质属性由曲线定义 (

Figure 2)。另一个小实体附着在梁端,并被设置为绝对刚体 (

Figure 4)。刚性实体被施加了力矩

,作为力矩传递单元。

Figure 4.

下表总结了下图中描述的模拟结果。

| 力矩 M [N*m] |

SOL 参考,弹性核心尺寸 [mm] |

SimSolid,近似弹性核心尺寸 [mm] |

% 差异 |

| 776.893 |

10.0 |

12.0 |

20.00% |

| 847.518 |

5.0 |

6.0 |

20.00% |

| 力矩 M [N*m] |

SOL 参考,最大位移 [mm] |

SimSolid,最大位移 [mm] |

% 差异 |

| 776.893 |

3.468 |

3.351 |

-3.37% |

| 847.518 |

6.937 |

6.918 |

-0.27% |