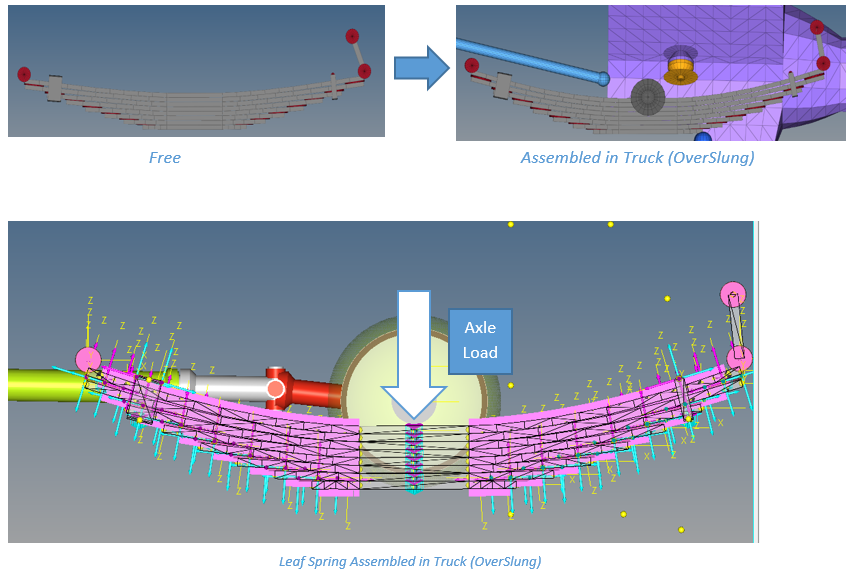

Assembled and Loaded Leaf Spring

An assembled and loaded Leaf Spring is used to model the leaf spring with information that one can easily retrieve. Generally, one can see the leaf spring assembled in trucks and also know the axle load on the leaf spring.

Figure 1.

To model the leaf spring with the Assembled and Loaded option, you will need the profile of the leaf spring in the final Loaded Position (after assembling in truck) along with the axle load on the leaf spring. It helps to build the leaf spring model with the provided shape, with preloads on each beam (each leaf in a leaf spring is modeled with a set of beams), which gives the overall load of the provided axle load.

- Moments at leaf eyes are 0.

- Moment at the axle comes equally from all of the leaves.

- For calculating the preloads, only the tip contacts are taken into consideration.

- Only master leaf and graduated leaves will take part in the design load. In other words, the design load will only be distributed among the master leaf and graduated leaves.

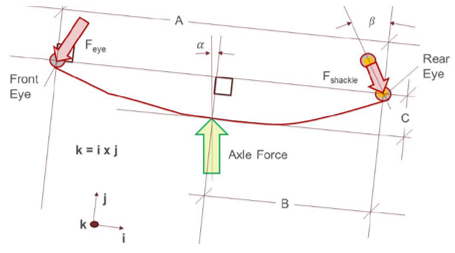

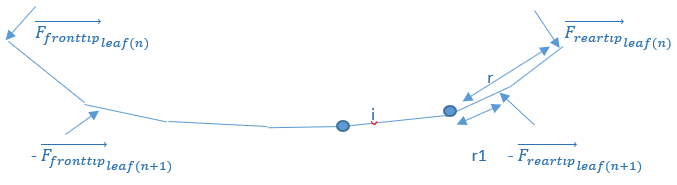

Leaf Spring in Design Shape

The following image shows the leaf spring in design shape, which is in equilibrium.

Figure 2.

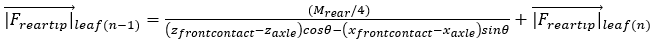

Moments due to these forces at axle are

If there are n leaves in the system, each leaf should contribute the moment of M/n according to the assumptions.

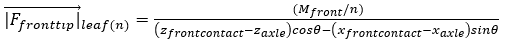

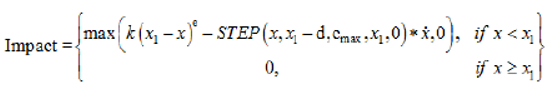

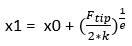

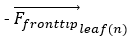

TipLoads

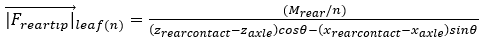

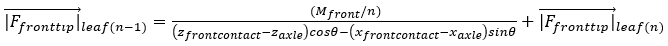

For the bottom most leaf to give M/n,

is angle at which contact force is

applied.

is angle at which contact force is

applied.

Similarly, tipLoads are calculated and X1's are changed for all leaves.

Preloads on Beams

Beams are preloaded to oppose the tipLoads for leaf to be in equilibrium:

Figure 3. Individual Leaf from Leaf Spring

For Beam i in leaf n,

Action-Reaction Force with Force and Moments as,

and rX

and rX  is added if the beam is on the front side

and

is added if the beam is on the front side

and

and rX

and rX  is added if the beam is on the rear side

is added if the beam is on the rear side

And also,

and r1X

and r1X  is added if the beam is on the front side

is added if the beam is on the front side

and r1X

and r1X  is added if the beam is on the rear side

is added if the beam is on the rear side