Multiphysics Solution

Thermal Analysis

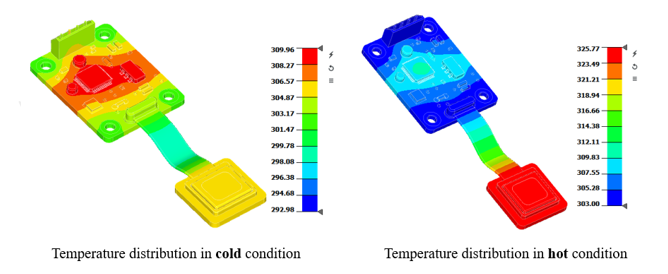

A fingerprint scanner is initially kept in cold conditions and then moved to hot conditions, the temperature variation, as well as the structural performance of scanner, is analyzed when it is moved from cold to hot, as well a hot to cold weather conditions.

Use-Case

Human fingerprints are practically unique, thus the application of a fingerprint scanner is enormous. As the weather changes from summer to fall to winter, fingerprint sensors on the devices may start to have troubles. The fact that heat makes things expand and cold makes them contract, it is necessary to evaluate the structural performance after the temperature variations.

FEA Model Description

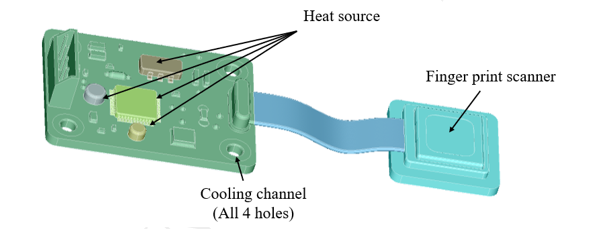

Figure 1. Fingerprint Scanner

Results

Figure 2. Temperature Distribution in Cold and Hot Conditions

Model File

Refer to Access the Model Files to download the required model file(s).

The model file used here includes:

Fingerprint_scanner.slb

Thermal Fluid-Structure Interaction Analysis

Thermal fluid interaction is accurately analyzed using OptiStruct.

Use-Case

A light bulb is a device that produces light from electricity. In addition to lighting a dark space, they can be used to indicate than an electronic device is on, to direct traffic, for heat, and many other purposes. If you want to change or replace a light bulb which has on for a long time, it will very hot to touch.

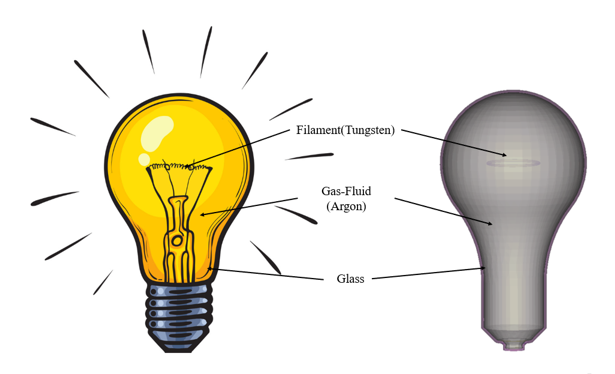

Figure 3. Thermal Fluid-Structure Interaction Analysis

FEA Model Description

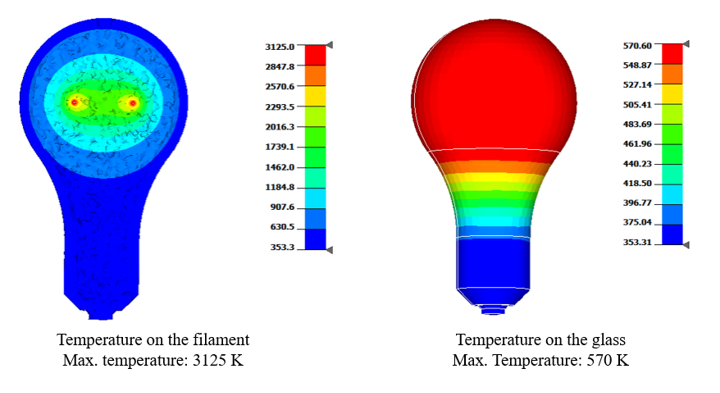

In this model, the air, which is fluid in this analysis, is meshed using SimLab and the filament gives heat generation, due to electricity of 1.2 W/mm3. The fluid mesh is an important step as it will transfer the heat from the filament to the glass. Appropriate material properties are given to the filament (tungsten), air-fluid (Argon gas), and glass. In this solution, CFD thermal flow is solved using AcuSolve and Structural Stress Analysis is solved using OptiStruct.

Results

Figure 4. Temperature Variation

Model File

Refer to Access the Model Files to download the required model file(s).

The model file used here includes:

light_bulb.slb