/MAT/LAW27 (PLAS_BRIT)

Block Format Keyword This law combines an isotropic elasto-plastic Johnson-Cook material model with an orthotropic brittle failure model. Material damage is accounted for prior to failure. Failure and damage occur only in tension. This law is applicable only for shells.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /MAT/LAW27/mat_ID/unit_ID or /MAT/PLAS_BRIT/mat_ID/unit_ID | |||||||||

| mat_title | |||||||||

| E | |||||||||

| a | b | n | |||||||

| c | ICC | Fsmooth | Fcut | ||||||

| dmax1 | |||||||||

| dmax2 | |||||||||

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| mat_ID | Material

identifier. (Integer, maximum 10 digits) |

|

| unit_ID | Unit Identifier. (Integer, maximum 10 digits) |

|

| mat_title | Material

title. (Character, maximum 100 characters) |

|

| Initial

density. (Real) |

||

| E | Young's

modulus. (Real) |

|

| Poisson's

ratio. (Real) |

||

| a | Plasticity yield

stress. (Real) |

|

| b | Plasticity hardening

parameter. (Real) |

|

| n | Plasticity hardening

exponent. (Real) |

|

| Plasticity maximum

stress. Default = 1030 (Real) |

||

| c | Strain rate coefficient.

Default = 0.00 (Real) |

|

| Reference strain

rate. If , no strain rate effect. (Real) |

||

| ICC | Strain rate computation

flag. 4

(Integer) |

|

| Fsmooth | Strain rate smoothing flag.

(Integer) |

|

| Fcut | Cutoff frequency for

strain rate smoothing. 5 Default = 1030 (Real) |

|

| Tensile failure strain at

which stress starts to reduce in the principal strain direction 1.

6 Default = 1.0 x 1030 (Real) |

||

| Maximum tensile failure

strain in principal strain direction 1 at which the stress in the

element is set to a value dependent on

dmax1.

6 Default = 1.1 x 1030 (Real) |

||

| dmax1 | Maximum damage factor in

principal strain direction 1. 6 Default = 0.999 (Real) |

|

| Maximum tensile strain for

element deletion in principal strain direction 1. 6 Default = 1.2 x 1030 (Real) |

||

| Tensile failure strain at

which stress starts to reduce in the principal strain direction

2. Default = 1.0 x 1030 (Real) |

||

| Maximum tensile strain in

principal strain direction 2 at which the stress in the element is

set to a value dependent on

dmax2. Default = 1.1 x 1030 (Real) |

||

| dmax2 | Maximum damage factor in

principal strain direction 2. 6 Default = 0.999 (Real) |

|

| Maximum tensile strain for

element deletion in principal strain direction 2. Default = 1.2 x 1030 (Real) |

Example (Aluminum)

#RADIOSS STARTER

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/UNIT/1

unit for mat

Mg mm ms

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#- 2. MATERIALS:

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

/MAT/PLAS_BRIT/1/1

Aluminum

# RHO_I

.0027

# E NU

60400 .33

# a b n SIG_max0

90.266 223.14 .375 177

# c EPS_DOT_0 ICC Fsmooth F_cut

0 0 0 0 0

# EPS_t1 EPS_m1 d_max1 EPS_f1

.16 .72 .999 1

# EPS_t2 EPS_m2 d_max2 EPS_f2

0 0 0 0

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|

#ENDDATA

/END

#---1----|----2----|----3----|----4----|----5----|----6----|----7----|----8----|----9----|---10----|Comments

- In this model, the material behaves as

a linear-elastic material when the equivalent stress is lower than the plastic

yield stress. For higher stress values, the material behavior is plastic and the

stress is calculated as.

(1) Where,- Plastic strain

- Strain rate

The plasticity hardening exponent, n must be less than 1.

- This law allows the modeling of material damage and brittle failure in two principal directions (1 and 2).

- This law is only applicable to shell elements. It is compatible with Shell Property (/PROP/TYPE1) and Sandwich Shell Property (/PROP/TYPE11).

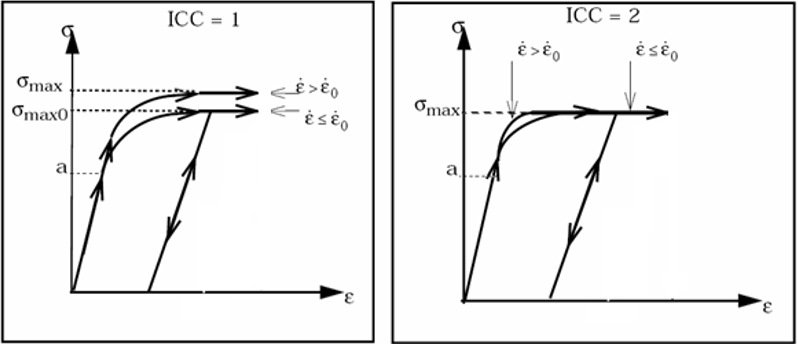

- The ICC flag defines the effect

of strain rate on the maximum material stress

. Figure 1 shows the value of

for the corresponding ICC flag.

Figure 1. - Strain rate smoothing is a process used to filter out higher strain rate frequencies.

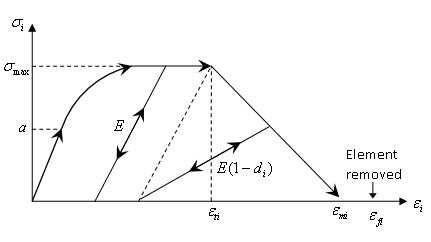

- When principal strain

becomes higher than

, then damage between

and

is controlled by the damage factor

, which is given by the following equation.

in directions, = 1, 2.

Stress is reduced according to damage parameter . Damage is reversible between and . When , damage is set to and it is not updated further.

Figure 2.