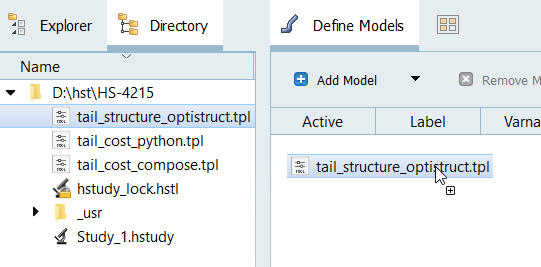

HS-4215: Multi-Disciplinary Design Optimization Study

Learn how to perform a multi-disciplinary design Optimization study. The disciplines used in this tutorial are structural performance and cost.

- tail.fem

- OptiStruct

- tail.oml

- Compose

- tail.py

- Python

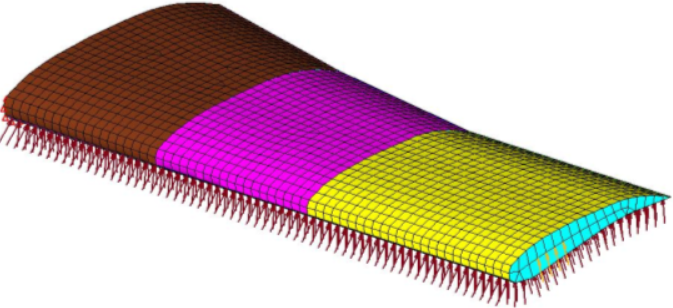

Figure 1. Horizontal Tail Plane Model

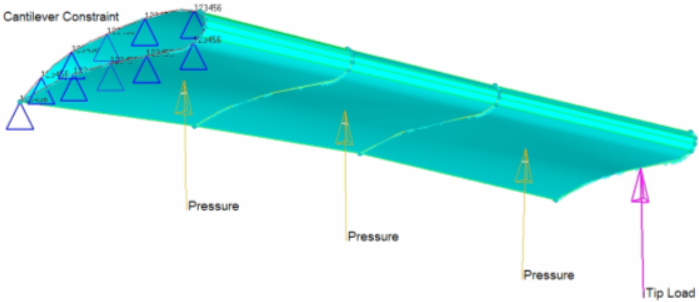

Figure 2. Loading Experienced by Horizontal tail plane

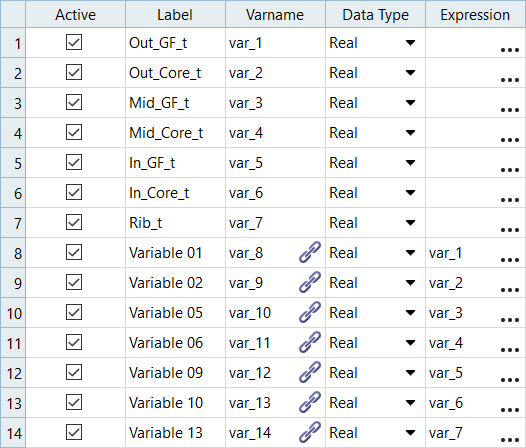

- Input variables

- Glass fabric thickness at inboards; initial value = 0.1; lower bound = 0.01, upper bound = 2.0

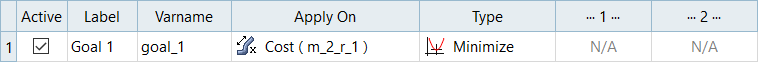

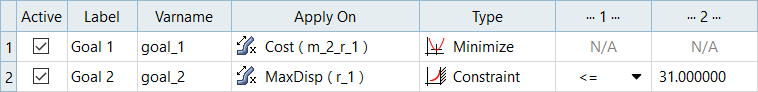

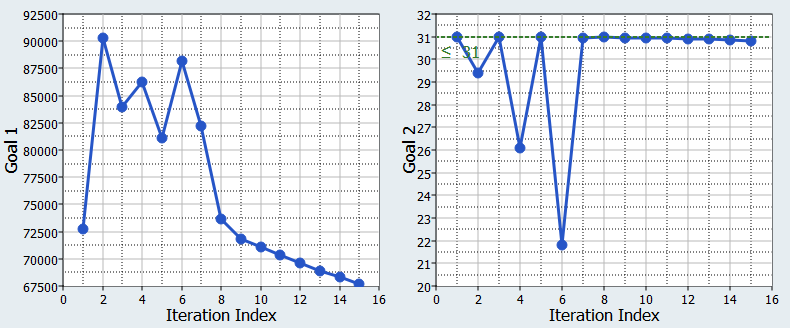

- Objective

- Minimize the cost

- Design constraints

- Maximum displacement must be less than its baseline value of 31

Perform the Study Setup

Perform Nominal Run

Create and Evaluate Output Responses

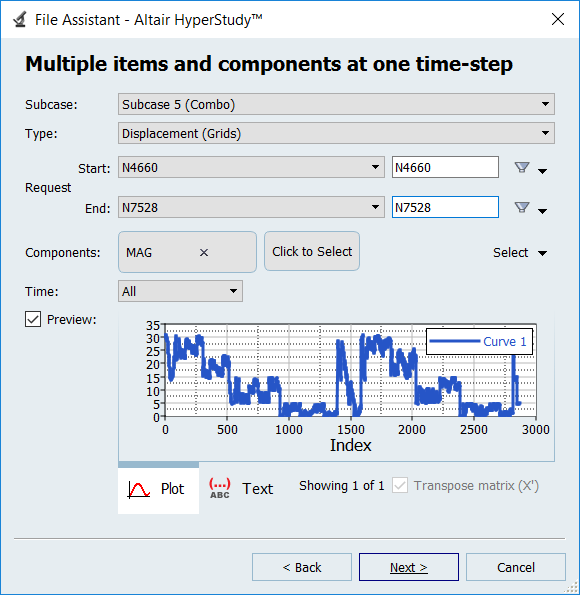

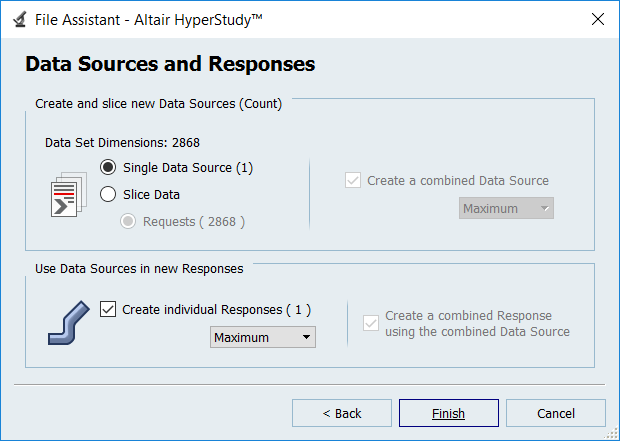

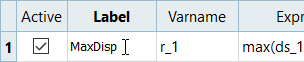

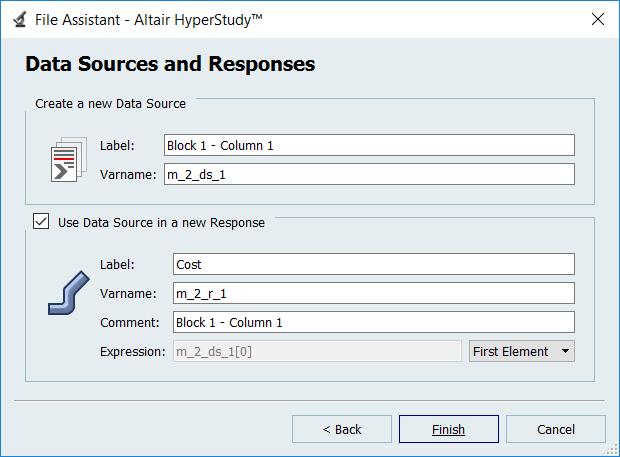

In this step you will create two output responses: MaxDisp and Cost.

- Go to the Define Output Responses step.

-

Create the MaxDisp output response.

-

Create the Cost output response.

- Click Evaluate to extract the response values.

.

.