OS-T: 1360 NLSTAT Analysis of Gasket Materials in Contact

This tutorial demonstrates how to carry out nonlinear implicit small displacement analysis in OptiStruct involving gasket materials and contact.

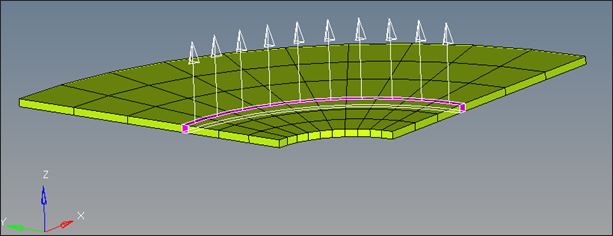

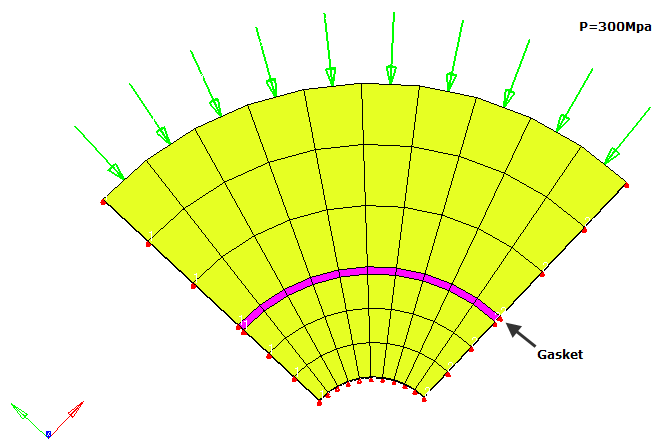

Figure 1. Model and Loading Description

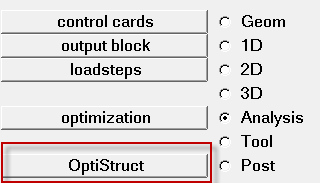

Launch HyperMesh and Set the OptiStruct User Profile

Open the Model

Set Up the Model

Create the Curves for Gasket Material

Create the Elasto-plastic Gasket Material

Next, you will define the nonlinear properties for the gasket material.

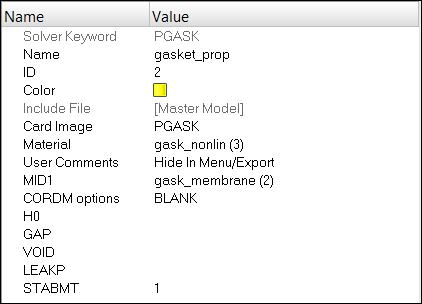

Create the Gasket Property

Assign 8-Noded Gasket Elements

- Click on the 3D page from the main menu.

- Click the elem types panel and click 2D & 3D.

- Click on elems, select by collector type and select the GASKET component.

- Toggle hex8 =, and select the CGASK8 element type.

- Click .

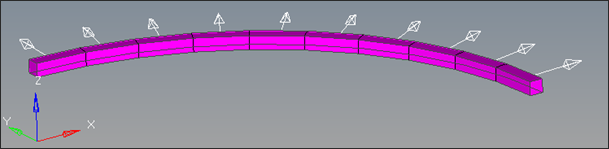

Review and Adjust the Normals of the Gasket Elements

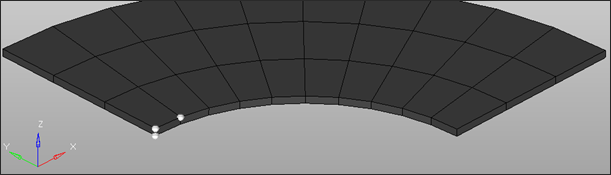

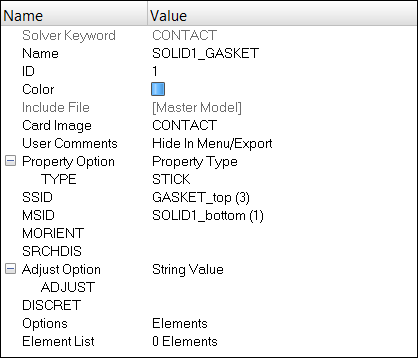

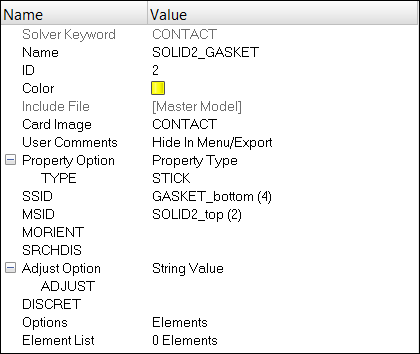

Define Contact between the Cylinders and Gasket

Now, an interface between the top cylinder and gasket are created.

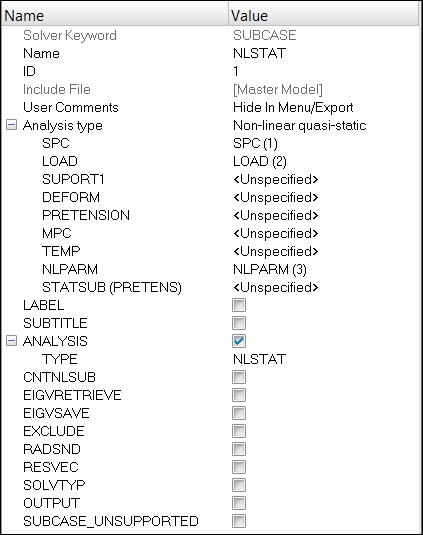

Define Nonlinear Implicit Parameters

Create NLSTAT Load Step

Define Output Control Parameters

- From the Analysis page, select control cards.

- Click on GLOBAL_OUTPUT_REQUEST.

- Below CONTF, DISPLACEMENT, STRAIN and STRESS, set Option to Yes.

- Click return twice to go to the main menu.

Submit the Job

View the Results

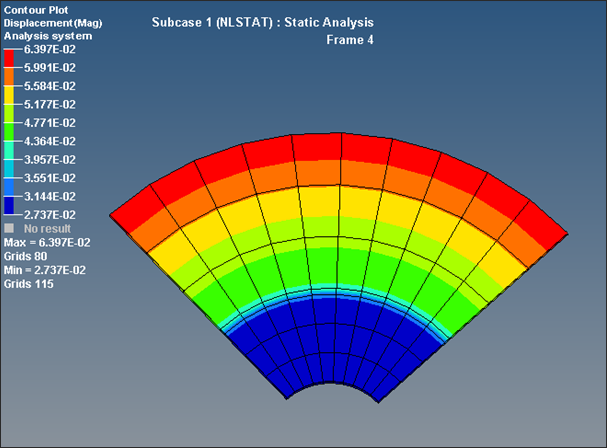

Figure 10. Contour of Displacements in Cylinders and Gasket Subject to Loading

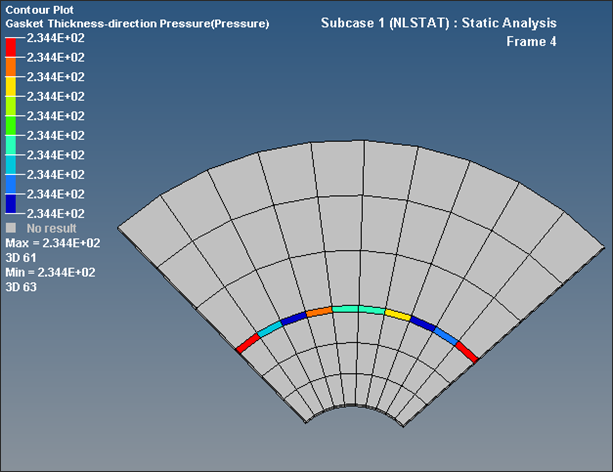

Figure 11. Contour of Gasket Thickness Direction Pressure

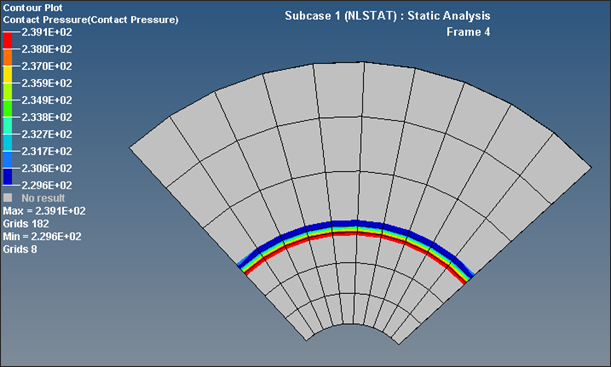

Figure 12. Contour of Contact Pressure

next to the Data field and enter the following values (X (closure) and Y (pressure)

fields) in the pop-out window.

next to the Data field and enter the following values (X (closure) and Y (pressure)

fields) in the pop-out window.