この材料モデルは、Ogden、Neo-Hookean、またはMooney-Rivlin材料モデルを使用して指定された超弾性、粘性、および非圧縮性の材料を定義します。この法則は、通常、非圧縮性のゴム、ポリマー、フォーム、およびエラストマーのモデル化に使用されます。この材料は、シェル要素とソリッド要素に使用できます。

LAW42は、以下のOgden材料モデルのひずみエネルギー密度表現を使用します。

(3)

W

(

λ

1

,

λ

2

,

λ

3

)

=

∑

p

=

1

5

μ

p

α

p

(

λ

¯

1

α

p

+

λ

¯

2

α

p

+

λ

¯

3

α

p

−

3

)

+

K

2

(

J

−

1

)

2

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGxbWaae

WaaeaacqaH7oaBdaWgaaWcbaGaaGymaaqabaGccaGGSaGaeq4UdW2a

aSbaaSqaaiaaikdaaeqaaOGaaiilaiabeU7aSnaaBaaaleaacaaIZa

aabeaaaOGaayjkaiaawMcaaiabg2da9maaqahabaWaaSaaaeaacqaH

8oqBdaWgaaWcbaGaamiCaaqabaaakeaacqaHXoqydaWgaaWcbaGaam

iCaaqabaaaaOWaaeWaaeaadaqdaaqaaiabeU7aSbaadaWgaaWcbaGa

aGymaaqabaGcdaahaaWcbeqaaiabeg7aHnaaBaaameaacaWGWbaabe

aaaaGccqGHRaWkdaqdaaqaaiabeU7aSbaadaWgaaWcbaGaaGOmaaqa

baGcdaahaaWcbeqaaiabeg7aHnaaBaaameaacaWGWbaabeaaaaGccq

GHRaWkdaqdaaqaaiabeU7aSbaadaWgaaWcbaGaaG4maaqabaGcdaah

aaWcbeqaaiabeg7aHnaaBaaameaacaWGWbaabeaaaaGccqGHsislca

aIZaaacaGLOaGaayzkaaaaleaacaWGWbGaeyypa0JaaGymaaqaaiaa

iwdaa0GaeyyeIuoakiabgUcaRmaalaaabaGaam4saaqaaiaaikdaaa

WaaeWaaeaacaWGkbGaeyOeI0IaaGymaaGaayjkaiaawMcaamaaCaaa

leqabaGaaGOmaaaaaaa@6C02@

ここで、

W

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGxbaaaa@373A@

ひずみエネルギー密度

λ

i

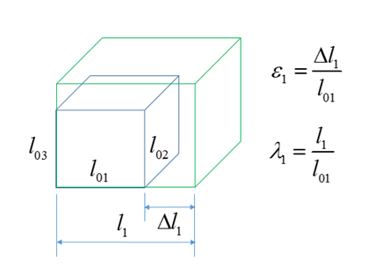

i th 主工学ストレッチ

J

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbaaaa@372D@

相対体積は次のように定義されます:

J

=

λ

1

⋅

λ

2

⋅

λ

3

=

ρ

0

ρ

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbGaey

ypa0Jaeq4UdW2aaSbaaSqaaiaaigdaaeqaaOGaeyyXICTaeq4UdW2a

aSbaaSqaaiaaikdaaeqaaOGaeyyXICTaeq4UdW2aaSbaaSqaaiaaio

daaeqaaOGaeyypa0ZaaSaaaeaacqaHbpGCdaWgaaWcbaGaaGimaaqa

baaakeaacqaHbpGCaaaaaa@4A3F@

λ

¯

i

=

J

−

1

3

λ

i

偏差ストレッチ

α

p

μ

p

材料定数係数ペア。

5つまでの材料定数ペアを定義できます。

初期せん断弾性率

μ

および体積弾性率(

K

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGlbaaaa@372E@

)は、次のように与えられます:

(4)

μ

=

∑

p

=

1

5

μ

p

⋅

α

p

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd0Maey

ypa0ZaaSaaaeaadaaeWbqaaiabeY7aTnaaBaaaleaacaWGWbaabeaa

kiabgwSixlabeg7aHnaaBaaaleaacaWGWbaabeaaaeaacaWGWbGaey

ypa0JaaGymaaqaaiaaiwdaa0GaeyyeIuoaaOqaaiaaikdaaaaaaa@4720@

および(5)

K

=

μ

⋅

2

(

1

+

ν

)

3

(

1

−

2

ν

)

ここで、

ν

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqyVd4gaaa@37AF@

材料パラメータ

パラメータ

α

p

および

μ

p

は、初期せん断弾性率が以下となるように選択されなくてはなりません:

(6)

μ =

∑

p = 1

5

μ

p

⋅

α

p

2

> 0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd0Maey

ypa0ZaaSaaaeaadaaeWbqaaiabeY7aTnaaBaaaleaacaWGWbaabeaa

kiabgwSixlabeg7aHnaaBaaaleaacaWGWbaabeaaaeaacaWGWbGaey

ypa0JaaGymaaqaaiaaiwdaa0GaeyyeIuoaaOqaaiaaikdaaaGaeyOp

a4JaaGimaaaa@48E2@

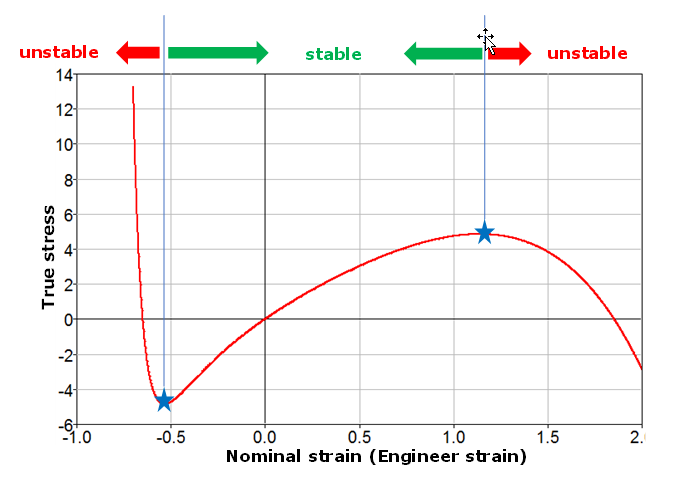

材料の安定性のためには、各材料定数ペアが以下のとおりである必要があります:

(7)

μ

p

⋅

α

p

>

0

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaH8oqBda

WgaaWcbaGaamiCaaqabaGccqGHflY1cqaHXoqydaWgaaWcbaGaamiC

aaqabaGccqGH+aGpcaaIWaaaaa@4015@

通常、Ogdenモデルは700%までのひずみに使用することができます。材料ペア

α

p

μ

p

Radioss で、もしくは別のフィッティングソフトウェアを介して行うことが可能です。

Neo-Hookeanモデル

Ogden材料モデルのシンプルなケースが、ひずみエネルギー密度関数の次の式を使用して表現可能なNeo-Hookenモデルです:

(8)

W =

C

10

(

I

1

− 3

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4vaiabg2

da9iaadoeadaWgaaWcbaGaaGymaiaaicdaaeqaaOWaaeWaaeaacaWG

jbWaaSbaaSqaaiaaigdaaeqaaOGaeyOeI0IaaG4maaGaayjkaiaawM

caaaaa@3F3E@

ここで、

I

1

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamysamaaBa

aaleaacaaIXaaabeaaaaa@37AC@

右Cauchy-Greenテンソルの第1不変量

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaaaaa@3860@

材料の定数

この表現は、次の場合に、LAW42 Ogdenひずみエネルギー密度関数から求められます:

μ

1

= 2 ⋅

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd02aaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaaGOmaiabgwSixlaadoeadaWg

aaWcbaGaaGymaiaaicdaaeqaaaaa@3F13@

α

1

= 2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqySde2aaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaaGOmaaaa@3A49@

μ

2

=

α

2

= 0

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd02aaS

baaSqaaiaaikdaaeqaaOGaeyypa0JaeqySde2aaSbaaSqaaiaaikda

aeqaaOGaeyypa0JaaGimaaaa@3DF6@

Neo-Hookeanモデルは、20%未満のひずみについてのみ正確であるシンプルなモデルです。

Mooney-Rivlinモデル

LAW42 Ogden材料モデルの少し複雑なケースが、ひずみエネルギー密度関数の次の式を使用して表現可能なMooney-Rivlinモデルです:

(9)

W =

C

10

(

I

1

− 3

) +

C

01

(

I

2

− 3

)

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4vaiabg2

da9iaadoeadaWgaaWcbaGaaGymaiaaicdaaeqaaOWaaeWaaeaacaWG

jbWaaSbaaSqaaiaaigdaaeqaaOGaeyOeI0IaaG4maaGaayjkaiaawM

caaiabgUcaRiaadoeadaWgaaWcbaGaaGimaiaaigdaaeqaaOWaaeWa

aeaacaWGjbWaaSbaaSqaaiaaikdaaeqaaOGaeyOeI0IaaG4maaGaay

jkaiaawMcaaaaa@4786@

ここで、

I

1

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamysamaaBa

aaleaacaaIXaaabeaaaaa@37AC@

I

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamysamaaBa

aaleaacaaIXaaabeaaaaa@37AC@

右Cauchy-Greenテンソルの第1および第2不変量

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaaaaa@3860@

C

01

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4qamaaBa

aaleaacaaIXaGaaGimaaqabaaaaa@3860@

材料の定数

この表現は、次の場合に、LAW42 Ogdenひずみエネルギー密度関数から求められます:

μ

1

=

2

⋅

C

10

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd02aaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaaGOmaiabgwSixlaadoeadaWg

aaWcbaGaaGymaiaaicdaaeqaaaaa@3F13@

μ

2

=

−

2

⋅

C

01

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqiVd02aaS

baaSqaaiaaikdaaeqaaOGaeyypa0JaeyOeI0IaaGOmaiabgwSixlaa

doeadaWgaaWcbaGaaGimaiaaigdaaeqaaaaa@4001@

α

1

=

2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqySde2aaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaaGOmaaaa@3A49@

α

2

=

-2

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqySde2aaS

baaSqaaiaaigdaaeqaaOGaeyypa0JaaGOmaaaa@3A49@

Mooney-Rivlin定数は、材料サプライヤーまたは試験会社から入手できます。入手できない場合、単軸試験データの曲線フィッティングがLAW69を用いてRadioss で、もしくは別のフィッティングソフトウェアを介して行うことが可能です。Mooney-Rivlin材料則は、100%までのひずみについて正確です。

ポアソン比と材料の非圧縮性

材料が真に非圧縮性である場合、

ν

=

0.5

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaeqyVd4Maey

ypa0JaaGimaiaac6cacaaI1aaaaa@3AE0@

。しかしながら、これは無限体積弾性率、無限音速、ひいては無限に小さいソリッド要素

時間ステップ をもたらすため、実践的には使用するのは不可能です。

(10)

K

=

μ

⋅

2

(

1

+

ν

)

3

(

1

−

2

ν

)

=

μ

⋅

2

(

1

+

ν

)

3

(

1

−

2

*

0.5

)

=

∞

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4saiabg2

da9iabeY7aTjabgwSixpaalaaabaGaaGOmamaabmaabaGaaGymaiab

gUcaRiabe27aUbGaayjkaiaawMcaaaqaaiaaiodadaqadaqaaiaaig

dacqGHsislcaaIYaGaeqyVd4gacaGLOaGaayzkaaaaaiabg2da9iab

eY7aTjabgwSixpaalaaabaGaaGOmamaabmaabaGaaGymaiabgUcaRi

abe27aUbGaayjkaiaawMcaaaqaaiaaiodadaqadaqaaiaaigdacqGH

sislcaaIYaGaaiOkaiaaicdacaGGUaGaaGynaaGaayjkaiaawMcaaa

aacqGH9aqpcqGHEisPaaa@5C83@

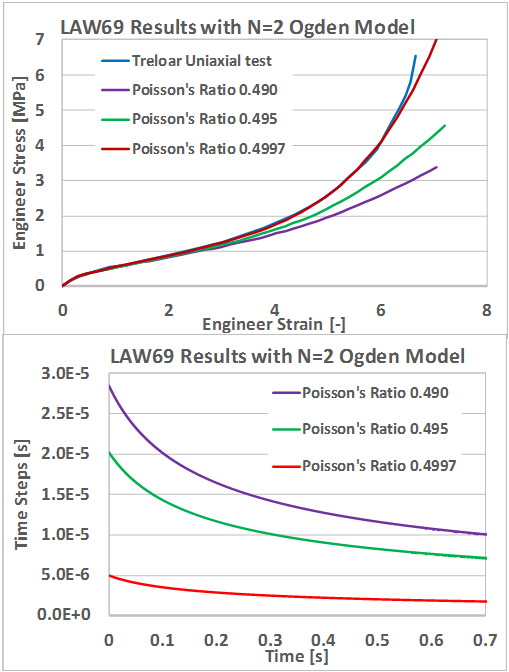

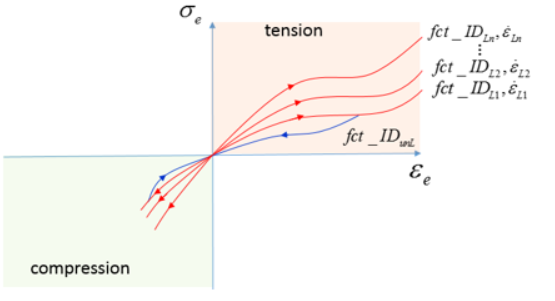

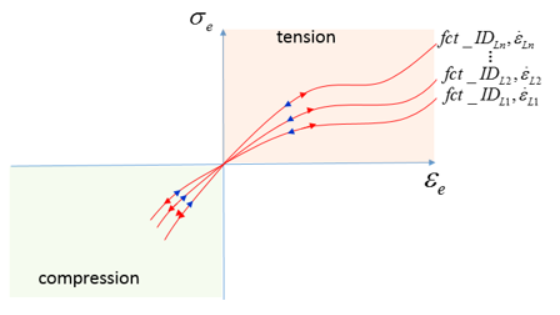

異なるポアソン比入力の影響は、図 2 に見られます。結果のうち最も大きな差は、より多くの量のひずみです。

ν

=

0.4997

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Jh9qqqrpepC0xbbL8F4rqGqFfpeea0xe9vq=Jb9

vqpeea0xd9q8qiYRWxGi6xij=hbba9q8aq0=yq=He9q8qiLsFr0=vr

0=vr0db8meaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaH9oGBcq

GH9aqpcaaIWaGaaiOlaiaaisdacaaI5aGaaGyoaiaaiEdaaaa@3E7A@

ν

=

0.495

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Jh9qqqrpepC0xbbL8F4rqGqFfpeea0xe9vq=Jb9

vqpeea0xd9q8qiYRWxGi6xij=hbba9q8aq0=yq=He9q8qiLsFr0=vr

0=vr0db8meaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaH9oGBcq

GH9aqpcaaIWaGaaiOlaiaaisdacaaI5aGaaGyoaiaaiEdaaaa@3E7A@

ν

=

0.495

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Jh9qqqrpepC0xbbL8F4rqGqFfpeea0xe9vq=Jb9

vqpeea0xd9q8qiYRWxGi6xij=hbba9q8aq0=yq=He9q8qiLsFr0=vr

0=vr0db8meaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaH9oGBcq

GH9aqpcaaIWaGaaiOlaiaaisdacaaI5aGaaGyoaiaaiEdaaaa@3E7A@

ポアソン比と体積弾性率の影響は、他のOgden材料則と同様になります。

図 2.

陽解法シミュレーションの場合は、ポアソン比を高くすると、時間ステップ値の極端な減少や発散につながる可能性があります。

LAW42では、材料の非圧縮性は、密度の変化に比例して圧力を計算するペナルティアプローチを使用して求められます:

(11)

P

=

K

⋅

F

s

c

a

l

e

b

l

k

⋅

f

b

l

k

(

J

)

⋅

(

J

−

1

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGqbGaey

ypa0Jaam4saiabgwSixlaadAeacaWGZbGaam4yaiaadggacaWGSbGa

amyzamaaBaaaleaacaWGIbGaamiBaiaadUgaaeqaaOGaeyyXICTaci

OzamaaBaaaleaacaWGIbGaamiBaiaadUgaaeqaaOWaaeWaaeaacaWG

kbaacaGLOaGaayzkaaGaeyyXIC9aaeWaaeaacaWGkbGaeyOeI0IaaG

ymaaGaayjkaiaawMcaaaaa@5293@

ここで、

K

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGlbaaaa@372E@

体積弾性率

J

=

V

V

0

=

m

ρ

0

m

ρ

=

ρ

0

ρ

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaamOsaiabg2

da9maalaaabaGaamOvaaqaaiaadAfadaWgaaWcbaGaaGimaaqabaaa

aOGaeyypa0ZaaSaaaeaacaWGTbGaeqyWdi3aaSbaaSqaaiaaicdaae

qaaaGcbaGaamyBaiabeg8aYbaacqGH9aqpdaWcaaqaaiabeg8aYnaa

BaaaleaacaaIWaaabeaaaOqaaiabeg8aYbaaaaa@4771@

質量が一定の場合に相対密度に簡易化される相対体積

f

b

l

k

(

J

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaciGGMbWaaS

baaSqaaiaadkgacaWGSbGaam4AaaqabaGcdaqadaqaaiaadQeaaiaa

wIcacaGLPaaaaaa@3CA0@

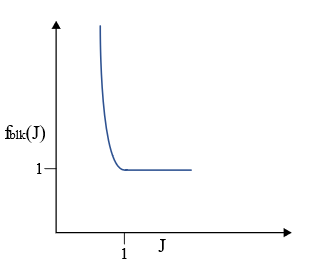

体積係数スケールファクターvs相対体積関数

F

s

c

a

l

e

b

l

k

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGgbGaam

4CaiaadogacaWGHbGaamiBaiaadwgadaWgaaWcbaGaamOyaiaadYga

caWGRbaabeaaaaa@3EBE@

右記の関数の横軸のスケールファクター;

f

b

l

k

(

J

)

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaaciGGMbWaaS

baaSqaaiaadkgacaWGSbGaam4AaaqabaGcdaqadaqaaiaadQeaaiaa

wIcacaGLPaaaaaa@3CA0@

超弾性材料の体積弾性率(

K

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGlbaaaa@372E@

)は一般的に非常に大きい値であり、非圧縮性条件(

J

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbaaaa@372D@

=1)を保持するために必要な圧力-抵抗を提供します。しかし、材料が圧縮し始めた場合(

J

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbaaaa@372D@

< 1)、体積係数値のスケーリングを

J

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbaaaa@372D@

の関数とすることが可能な

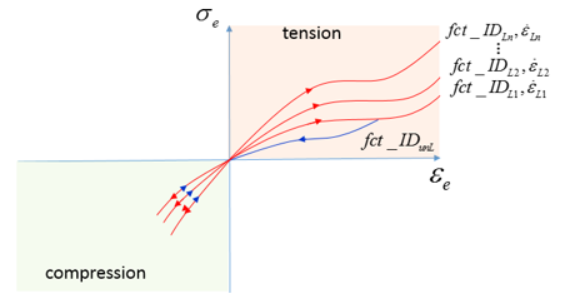

fct_ID blk 入力関数を含めることにより、体積弾性率を増加させることができます。デフォルトではスケーリングはなく、関数識別子が0であれば、体積スケーリング関数の値は1に等しくなります。密度のばらつきが小さくなるように、つまり、

J

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGkbaaaa@372D@

の値が1に近付き材料が非圧縮性であるよう、LAW42コンポーネントの材料密度を出力(

/ANIM/BRICK/DENS )し、確認することが推奨されます。

図 3. 体積弾性率スケールファクター関数fct_ID blk

粘性(速度)効果

LAW42ではMaxwellモデル(剛性

G

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbWaaS

baaSqaaiaadMgaaeqaaaaa@3844@

とダンパ

η

i

を持つn個のスプリングの系として簡単に記述することができる)を使用した粘性(速度)効果がモデル化されます:

図 4. Maxwellモデル

Maxwellモデルは、Prony級数の入力(

G

i

,

τ

i

MathType@MTEF@5@5@+=

feaagKart1ev2aqatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbba9pwe9Q8fs0=yqaqpepae9pg0FirpepeKkFr0xfr=x

fr=xb9adbaqaaeGaciGaaiaabeqaamaabaabaaGcbaGaam4ramaaBa

aaleaacaWGPbaabeaakiaacYcacqaHepaDdaWgaaWcbaGaamyAaaqa

baaaaa@3B76@

)を使って表現されます。超弾性初期せん断弾性率

μ

は、Maxwellモデルの長期せん断弾性率

G

∞

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbWaaS

baaSqaaiabg6HiLcqabaaaaa@38C7@

と同じであり、

τ

i

は緩和時間です:

(12)

τ

i

=

η

i

G

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacqaHepaDda

WgaaWcbaGaamyAaaqabaGccqGH9aqpdaWcaaqaaiabeE7aOnaaBaaa

leaacaWGPbaabeaaaOqaaiaadEeadaWgaaWcbaGaamyAaaqabaaaaa aa@3F13@

G

i

MathType@MTEF@5@5@+=

feaagKart1ev2aaatCvAUfeBSjuyZL2yd9gzLbvyNv2CaerbuLwBLn

hiov2DGi1BTfMBaeXatLxBI9gBaerbd9wDYLwzYbItLDharqqtubsr

4rNCHbGeaGqiVu0Je9sqqrpepC0xbbL8F4rqqrFfpeea0xe9Lq=Jc9

vqaqpepm0xbbG8FasPYRqj0=yi0dXdbba9pGe9xq=JbbG8A8frFve9

Fve9Ff0dmeaabaqaciGacaGaaeqabaWaaeaaeaaakeaacaWGhbWaaS

baaSqaaiaadMgaaeqaaaaa@3844@

τ

i