/FAIL/GURSON

ブロックフォーマットのキーワード 金属の塑性におけるボイドの発生と成長の観点から損傷を記述するGurson-Nahshon-Hutchinson破壊モデル。

修正されたGurson定式化では、いくつかの損傷累積項が追加されています。これらの損傷累積項は、せん断が支配的である荷重、圧縮荷重下での特別な取り扱い、損傷に伴う弾性剛性損失に関する項です。

フォーマット

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| /FAIL/GURSON/mat_ID/unit_ID | |||||||||

| Iloc | |||||||||

| As | Kw | ||||||||

| Rlen | Hchi | ||||||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| fail_ID |

定義

| フィールド | 内容 | SI単位の例 |

|---|---|---|

| mat_ID | 材料識別子 (整数、最大10桁) |

|

| unit_ID | (オプション)単位識別子 (整数、最大10桁) |

|

| 1番目のGurson損傷係数。 デフォルト = 1.5(実数) |

||

| 2番目のGurson損傷係数(最大値 = 1.02)。 デフォルト = 1.0(実数) |

||

| Iloc | 損傷変数累積手法のフラグ。

(整数) |

|

| ボイド発生時の相当塑性ひずみ。 (実数) |

||

| As | 線形ボイド発生勾配。 (実数) |

|

| Kw | せん断損傷成長係数。 (実数) |

|

| ボイド凝集時の臨界ボイド体積率。 (実数) |

||

| 延性破壊時のボイド体積率。 (実数) |

||

| 初期ボイド体積率 (実数) |

||

| Rlen | 非局所変数による影響の半径(Iloc > 1)。 (実数) |

|

| Hchi | 非局所ペナルティパラメータ(微細形態法専用、Iloc = 2)。 (実数) |

|

| メッシュ収束基準となる要素長さ 5 (実数) |

||

| fail_ID | (オプション)破壊基準識別子。 (整数、最大10桁) |

コメント

- Gurson損傷モデルは、弾塑性材料則/MAT/LAW104にのみ使用することができます。この材料則の降伏曲面は、次の損傷進展項を追加することによって修正されています。

(1) ここで、- 、

- 2つのGurson-Tveergard-Needlemanパラメータ。

- 実効損傷

- 次のように定義した係数:

- 増分を使用して計算する合計ボイド体積率。

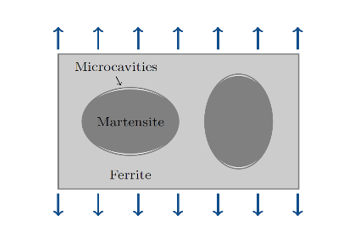

損傷係数増分の運動方程式は次のとおりです。- ボイド発生(微小空洞の発生)。3軸性が低い場合は低下。

(2) ここで、 は次のように応力に定義した3軸性です。(3)

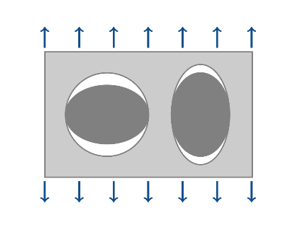

図 1. 空洞の発生 - 3軸性が高い場合のボイド成長:

(4)

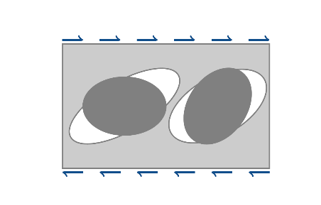

図 2. 3軸性が高い場合の空洞の成長 - せん断が支配的な3軸性が低い場合の追加のせん断ボイド成長:

(5) ここで、 はLode角に依存する重み関数です。(6)

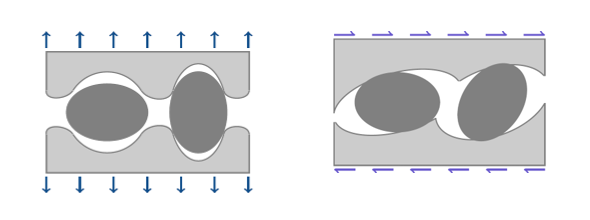

図 3. 3軸性が低い場合の空洞の成長によって臨界ボイド体積率 に達したときの空洞の凝集を表現するには、実効損傷(この損傷は応力の計算に影響します) をモデルに導入します。その式は、次のように に依存します。(7) ここで、 は破断時の合計ボイド体積率であり、この体積率では が成り立ちます。

図 4. 空洞の凝集剛性損失の影響を考慮するには、損傷変数 を次のように計算します。(8) 実効損傷 はその破断値 で正規化します。これによって となります。応力テンソルは次の式で求められます。(9) ここで、 は弾性剛性マトリックスです。

累積した合計損傷係数が限界値 に達すると材料は破断します。その結果、要素が削除されます。

- デフォルト設定の

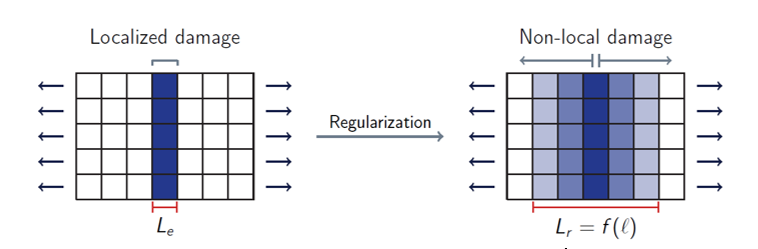

では、積分点ごとに局所塑性ひずみ値を使用して、損傷変数が段階を追って計算されます。ただし、非局所正則化を使用することもできます。その場合は、ユーザーが設定した最大値以下のメッシュサイズ

(

)を使用して、メッシュのサイズと方向に依存しない結果(メッシュの収束)がすべてのメッシュで得られます。その場合、この最大メッシュサイズ

は、結果がメッシュ収束である場合に使用する最大メッシュサイズです。 いずれかの非局所定式化 を使用する場合、損傷の増分は、メッシュ全体で計算した節点の“非局所”塑性ひずみを正則化した値に依存します。節点における非局所塑性ひずみ の計算では、この塑性ひずみ独自の勾配が考慮されると共に、以下の一組の方程式に従ってガウス点で計算した局所塑性ひずみ が考慮されます。

(10) パラメータ および は自動的に設定されます。ユーザーは、パラメータRlen(または - コメント 5 )を設定する必要があります。このパラメータによって、非局所変数計算における影響半径に相当する非局所“内部長”が決まります。これにより、非局所正則化幅 のサイズが決定されます(図 5)。

図 5. 非局所正則化の原理パラメータRlenの値を選択するには次の式に従います。(11) -

の場合は、非局所微細形態法が使用されます。この手法では、パラメータHchiが必要です。このパラメータと非局所塑性ひずみ

を、次のように構成方程式に導入します。

(12) ここで、 は従来から使用されている加工硬化関数です。この新たに定義した微細形態加工硬化関数Rchiを、流動応力 の計算に導入します。パラメータHchiはペナルティパラメータになり、 であれば、 および となり、したがって となります。この手法は熱力学的に明確に定義されています。ただし、この手法では入力値の特定が困難で、それによってモデルの塑性挙動が変化します。このことから、Peerlings法( とする手法)の使用をお勧めします。

-

の場合は、非局所なPeerlings法を使用します。この手法では、パラメータHchiを使用します。非局所長さRlenのみが使用されます。この手法は微細形態法より簡潔です。この手法では、軟化変数運動方程式に非局所塑性ひずみを導入しています(熱効果を考慮する場合は損傷と温度)。

(13) (14) この手法をお勧めする理由は、この手法では入力パラメータの特定が簡潔で、材料の塑性挙動が変化しないことにあります。

- 非局所長さパラメータRlenを設定する場合、以下を選択することができます:

- このパラメータを直接制御する必要がある場合は、入力カードにRlenの値を直接入力します。この場合、パラメータ は無視してnoneに設定する必要があります。

- 結果がメッシュ収束に達した最大メッシュサイズ を入力します。非局所正則化は、すべてのメッシュサイズ ( など)に対して有効になります。この場合、Rlenは の値に従って自動的に計算され、Rlenの入力値は無視されます。たとえば、メッシュサイズが5mm、 mmの場合に、収束したメッシュに依存しない結果を取得する場合です。このケースでは、 mmの場合、結果は収束し、メッシュサイズとメッシュ方向に依存しません。

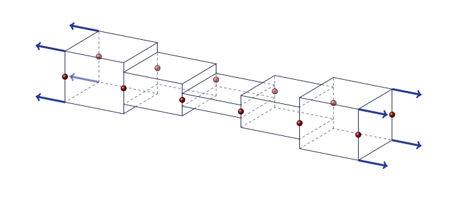

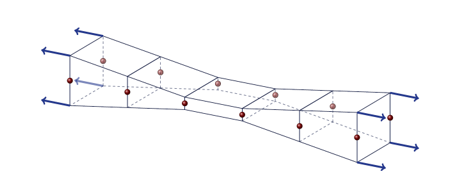

- 非局所正則化をシェル要素に使用すると、厚みの変化の計算で正則化が別途実行されることにより、局所化に伴う新たな問題の発生を回避できます。一般的な局所ケースでは(図 6)、シェル要素間の厚みの適合性を確保できません。その理由は、z方向の運動方程式が欠落しており、厚みの変化がガウス点で局所的に計算されることにあります。“厚みの範囲”でのひずみ増分に非局所塑性ひずみを導入することで、この適合性を回復できます(図 7)。

(15) ここで、 は非局所塑性乗数です。

図 6. 横ひずみの不適合性(局所)

図 7. 横ひずみの適合性(非局所)注: この最後の点は、特定したパラメータをソリッドとシェルに使用できることを意味します。両者は、同じ応力3軸性 の範囲内で結果がまったく同じになるからです。 - ANIMファイルとH3Dファイルに特定の損傷出力DAMAを作成するには、次のように合計損傷をその破断値で正規化します。

(16)