FATSEAM

Bulk Data Entry Used to define parameters and property identification data for Seam Weld Fatigue Analysis.

Format

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

|---|---|---|---|---|---|---|---|---|---|

| FATSEAM | ID | WTYPE | REFEID | WLDSIDE | |||||

| PSHELL | PID1 | PID2 | etc | etc | etc | etc | PID7 | ||

| PID8 | PID9 | etc | |||||||

| ELSET | SETID1 | SETID2 | SETID3 | SETID4 | SETID5 | SETID6 | SETID7 | ||

| SETID8 | SETID9 | SETID10 | etc |

Definitions

| Field | Contents | SI Unit Example |

|---|---|---|

| ID | Each

FATSEAM card must have a unique ID. No default (Integer > 0) |

|

| WTYPE | Weld type.

No default |

|

| REFEID | Reference element

identification number. 3 Default = blank (Integer > 0) |

|

| WLDSIDE | Weld side. 4

(Integer) |

|

| PSHELL | Indicates that the following property fields reference PSHELL entries. | |

| PIDi | Property identifier of

weld elements. 1 No default (Integer > 0) |

|

| ELSET | Indicates the following fields reference element SET IDs. | |

| SETIDi | Element SET ID of weld

elements. 1 No default (Integer > 0) |

Comments

- For the Volvo method

(METHOD=VOLVO on

FATPARM), the seam weld elements should be modeled with

CQUAD4 or CTRIA3 elements only that

reference PSHELL properties. CTRIA3

elements should only be used for corner or end closing. For the Volvo method,

both PSHELL and ELSET continuation lines

can be used to identify the weld elements. In the case of

ELSETs, they should only reference sets of

CQUAD4 or CTRIA3 elements that

reference PSHELLs.

For the Joint Line method (METHOD=JNTLINE on FATPARM), the seam weld elements should be modeled with PLOTEL elements only. The FATDEFnode numbering of the PLOTELs is not relevant and the PLOTEL elements only serve to identify the weld line and do not structurally affect the solution. For the Joint Line method, only the ELSET continuation line can be used to identify the set(s) of PLOTEL elements.

- The FATDEF Bulk Data Entry may reference this identifier via the FATSEAM continuation line.

- REFEID defaults are

governed by the following conditions:

- If WTYPE is set to T, REFEID is mandatory.

- If WTYPE is set to L, and there are three shell plates joined at the weld line, then REFEID is mandatory.

- WLDSIDE defaults

are governed by the following conditions:

- If WTYPE is set to T, GENERIC, and BUTT, then WLDSIDE is not mandatory.

- If WTYPE is set to L and there are three shell plates joined at the weld line, then WLDSIDE is mandatory.

- If WTYPE is set to L and there are two shell plates joined at the weld line, and WLDSIDE is blank, then the weld is located at the smaller angle side of the two shell plates.

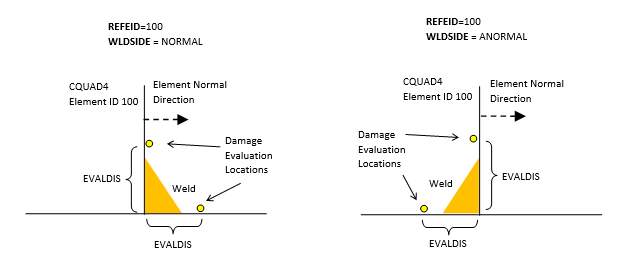

- If specified,

REFEID and WLDSIDE are used together

to identify the direction in which the weld exists. REFEID

identifies an element connected to the weld line, and WLDSIDE

identifies the direction of the weld, with respect to the element normal of the

element identified via REFEID. Figure 1 can help clarify how the weld

location is identified. EVALDIS is the evaluation distance

specified on the PFATSMW entry.

Figure 1. L Fillet Joint Example (WTYPE=L)